In materials research, the ability to accurately measure forming limit curves (FLCs) is essential for tool and die designers, FE experts, and others involved in the sheet metal stamping industry. While stereo digital image correlation (3D DIC) coupled with mechanical forming tests has been the state-of-the-art method for FLC testing, its high cost makes it infeasible in budget-constrained settings, such as academia. That’s where the latest work of Dr. Akshat Agha, a materials researcher with FADI-AMT LLC, South Carolina USA, comes in.

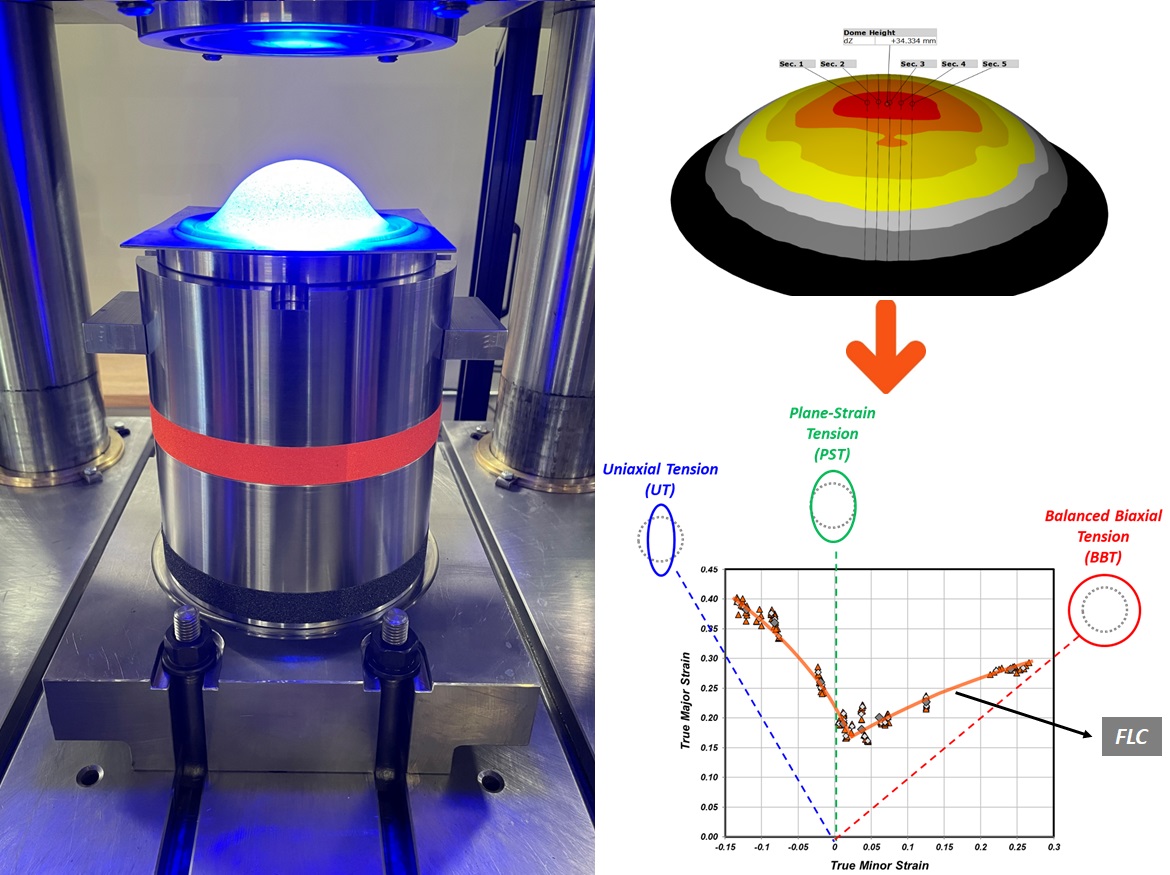

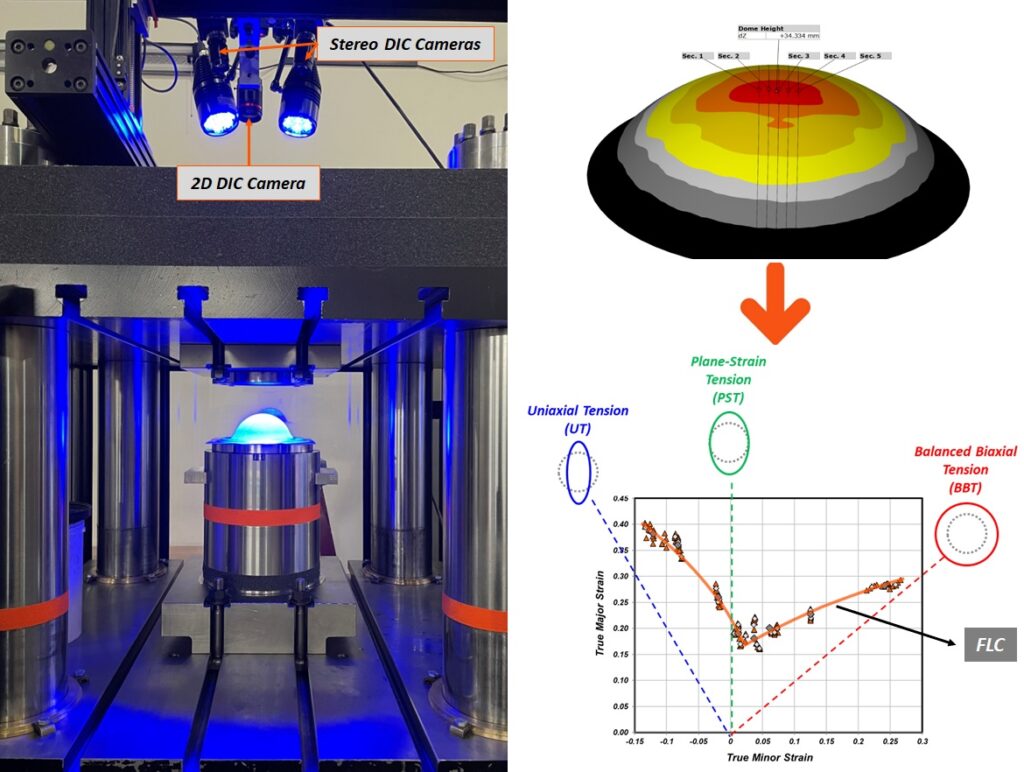

Recently, Dr. Agha proposed an innovative method for measuring FLCs using a low-cost single-camera 2D digital image correlation (DIC) system. While 2D DIC is generally considered less accurate due to potential errors from out-of-plane deformations in test samples or cameras (which is the case with popular forming tests like the Nakajima ball punch test or Marciniak flat punch test), this method overcomes this limitation using a mathematical approach to correct the recorded strains.

The researcher has validated this approach for in-plane Marciniak tests as well as out-of-plane Nakajima tests for high-strength steel (Dual-phase 980 steel) and a 6000 series aluminum alloy. The FLCs obtained by this method were validated against FLCs obtained by stereo DIC and showed an excellent match. By developing this new method of FLC testing with a 2D DIC system, Dr. Agha has opened up new possibilities for researchers and engineers to study and improve sheet metal forming processes using cost-effective technology. Dr. Agha has got his work published in the SAE International Journal [1] and recently presented his work to the materials research community in a guest talk in a webinar organized by FADI-AMT LLC (Link to watch the recorded webinar is below) [2].

The potential impact of this work goes beyond the materials research community. By making digital image correlation technology more accessible, more researchers and engineers can benefit from this powerful tool to better understand material properties and design better processes and products. The researcher’s dedication to improving the depth of knowledge of materials and promoting faster adoption of new technologies is inspiring and could lead to future breakthroughs in the field.

Overall, this proposed method using a single-camera 2D DIC system to measure FLCs is a significant contribution to the materials research community. It provides a cost-effective solution that makes it more accessible to a wider range of researchers and engineers, potentially leading to new discoveries and advancements in the field. We look forward to seeing the impact of this work in the years to come and are excited to see what he will achieve in future research endeavors.

[1] Agha, A., and Abu-Farha, F., “A Method for Measuring In-Plane Forming Limit Curves (FLC) using 2D Digital Image Correlation,” SAE MobilityRxiv™ Preprint, submitted February 5, 2023, https://doi.org/10.47953/SAE-PP-00322.

[2] https://subscribepage.io/fadi-amt-webinar-2023-02-1BC

Click on the following link Metrologically Speaking to read more such blogs on Metrology.