The advancements of modern-day technology within the medical field are fascinating in many ways. Still, the lack of individualization and on-demand availability has meant some serious side-effects for patients in need of implants, prostheses or other medical devices. Luckily, through the impact of combining one the world’s most adaptive and revolutionary manufacturing technologies with the metal of the future, titanium, that’s all about to change.

Life-threatening accidents, vertebral damage, chronic osteopathic conditions and side-effects from medical treatment can all cause irreparable damage for the patients. The consequences can be painful, debilitating and even fatal.

Titanium has excellent properties and is one of few metals accepted by the human body

Medical implant technology has developed vastly over the years, and one of manufacturing’s most disruptive technologies is set to transform the way we treat patients. The medical implant developers require a manufacturing technology that delivers speed, individualization and the ability to produce tailor-made and complex designs. Therefore, 3D printing, paired with materials like titanium, is demonstrating its evident potential as the medical industry’s manufacturing technology of choice for life-changing solutions.

“Titanium has excellent properties and is one of few metals accepted by the human body, while 3D printing can rapidly deliver results for an industry where acting quickly could be the difference between life and death,” says Harald Kissel, R&D Manager at Sandvik Additive Manufacturing.

Harald Kissel, R&D Manager at the Additive Manufacturing division at Sandvik.

Harald Kissel, R&D Manager at the Additive Manufacturing division at Sandvik.

Sandvik has leading capabilities across the entire additive manufacturing value chain – and offers the widest alloy program on the market for 3D printing. The company has recently inaugurated one of the world’s most cutting-edge titanium powder plants in Sweden. Within the walls of the highly automated plant, the well-renowned Osprey® titanium powders are produced, certified for use in the most advanced medical applications.

In addition to titanium’s material benefits, additive manufacturing can help overcome some of the challenges when producing medical implants and prosthetics. Typically, the process of being fit for a prosthesis involves several visits to create a device that fits a patient and their needs. As a result, the time between a patient’s life-changing surgery and them receiving their device can be painstakingly slow.

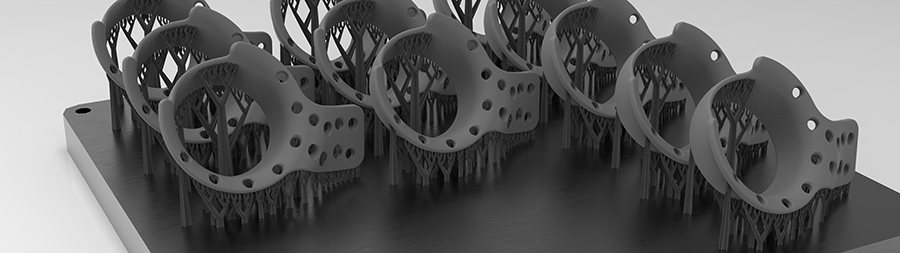

3D-printed implants for use when additional support for fixation of a hip prothesis is needed. Courtesy of Swiss m4m Center.

3D-printed implants for use when additional support for fixation of a hip prothesis is needed. Courtesy of Swiss m4m Center.

“If a patient undergoes a serious accident, one that destroys areas such as the skull or spine beyond repair, they simply do not have time to spare to ensure their reconstructive devices fit correctly. Instead, they’re given solutions that work, but aren’t tailor-made exactly to their bodies,” Harald Kissel explains.

Long waiting times and a lack of customization can really impact how a patient feels.

Using computer tomography, it is now possible to tailor-made the medical device directly from an individual’s anatomical data. These kind of customized designs cannot be produced using other manufacturing methods than additive manufacturing. Patients receive a perfectly matching device, in less time – 3D printed in a high-performing, lightweight material.

“Long waiting times and a lack of customization can really impact how a patient feels after they’ve undergone a life-changing event or procedure. Even in 2020, there are still prosthetic patients using devices that do not move, or are simply just hooks.”

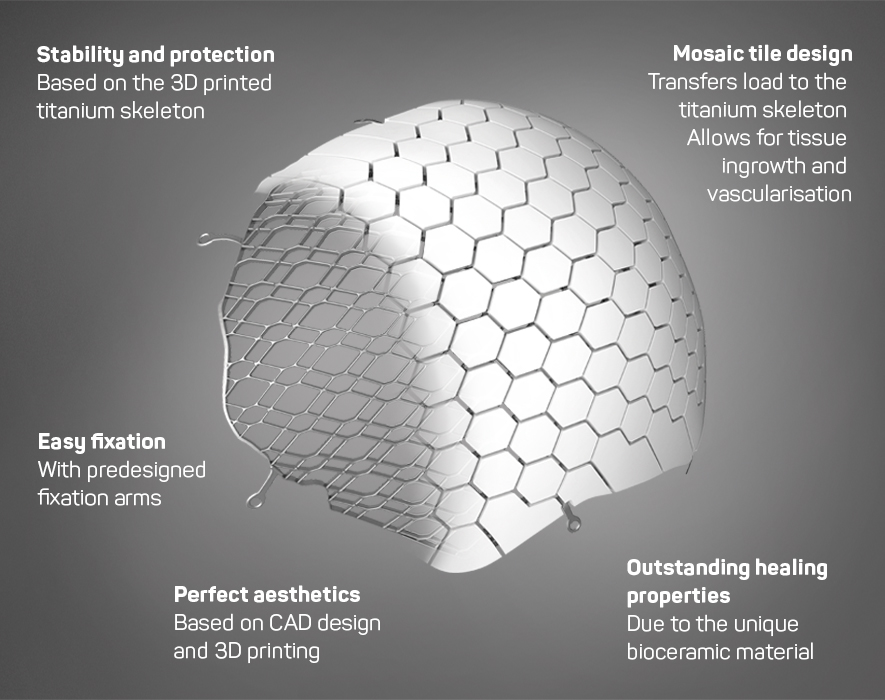

Another innovator within the medical sector is OssDsign – a medtech company dedicated to creating cranial implants for improved healing of bone defects. They provide neurosurgeons and reconstructive plastic surgeons around the world with an expanding range of innovative implant solutions, in part made from a 3D printed titanium mesh, for improved patient outcomes.

3D printed cranial implant. Courtesy of OssDsign.

3D printed cranial implant. Courtesy of OssDsign.

Kajsa Björklund, Director Technical Operations at OssDsign.“Being able to combine additive manufacturing of a reinforcing structure with our own proprietary ceramic material is really what defines OssDsign, and has allowed us to evolve into the world’s premiere manufacturer of tailor-made cranial implants,” says Kajsa Björklund, Director Technical Operations at OssDsign. “Titanium, with its proven biocompatibility, is a natural choice of material for a medical application such as ours – and additive manufacturing makes it possible for us to design and manufacture unique implants for each and every patient in need of a cranial reconstruction”.

Kajsa Björklund, Director Technical Operations at OssDsign.“Being able to combine additive manufacturing of a reinforcing structure with our own proprietary ceramic material is really what defines OssDsign, and has allowed us to evolve into the world’s premiere manufacturer of tailor-made cranial implants,” says Kajsa Björklund, Director Technical Operations at OssDsign. “Titanium, with its proven biocompatibility, is a natural choice of material for a medical application such as ours – and additive manufacturing makes it possible for us to design and manufacture unique implants for each and every patient in need of a cranial reconstruction”.

To reinvent the future of medical devices as well as the lives of thousands of people, is an experience out of the ordinary

Sandvik is also part of one of the most ground-breaking research projects within the medical segment to date, contributing with its extensive material expertise. The Swiss M4M Center in Switzerland is a public-private partnership initiated by the Swiss government, aiming to evolve medical 3D printing to a level where patient-specific, innovative implants can be developed and manufactured quickly, with high quality and cost-effectively.

3D printed medical components, courtesy of Swiss m4m Center.

3D printed medical components, courtesy of Swiss m4m Center.

“The Swiss M4M Center is intended to build up and certify a complete end-to-end production line for medical applications, like implants. Being able to facilitate this initiative through the unique material knowledge that is found within Sandvik is an empowering experience. Joining forces with an array of experts, to reinvent the future of medical devices as well as the lives of thousands of people, is an experience out of the ordinary,” Harald Kissel concludes.