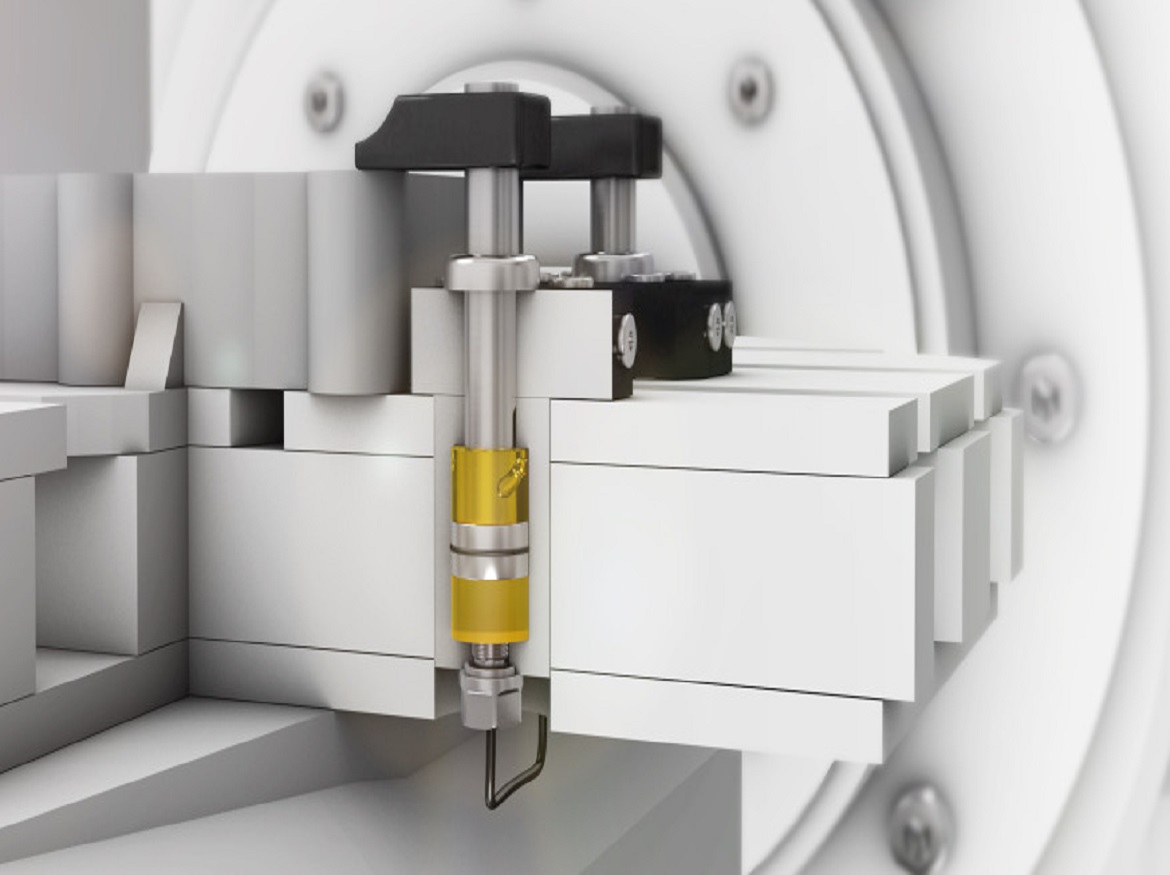

Whether detecting position, distance measurement, or the detection of solid, powdery or liquid media, ultrasonic sensors from Balluff are versatile. With tise BFD ultrasonic position sensor with media contact, we are expanding our portfolio to add an innovative way to directly monitor hydraulic short-stroke cylinders.

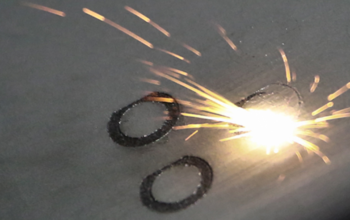

This reliable and economical solution for workpiece clamping monitoring is a real milestone in the field of metalworking.

Direct response to increasing production requirements

Existing solutions for monitoring workpiece clamping are based on indirect methods: they measure the volume flow of the hydraulic fluid or monitor the piston end position. However, such solutions are either cost-intensive, inflexible or less reliable.

In addition, conventional products cannot detect and monitor the clamping state and the clamping travel equally. As a result, they are not only not particularly economical, but also cannot always meet the increasing demands on machine safety.

Our new ultrasonic position sensor provides a remedy: By emitting ultrasound into the hydraulic fluid, the BFD monitors the clamping process of the workpiece directly, continuously and quickly. This generates reliable information on the clamping status and lets you detect deviations early on, like problems with the oil supply, casting errors, contour deviations, insertion errors and deformed workpieces. By monitoring the entire clamping process, you can also spot pressure fluctuations in the hydraulic unit, defects in the swivel mechanism and defective seals in ample time to take action.

In short, with the new BFD ultrasonic position sensor, Balluff is directly addressing customer needs and expectations–a solution that is innovative and yet has the potential to establish itself as a standard.

Easy integration and scalable use

Thanks to its small form factor, standardized interfaces that can be configured as required, and continuous automated compensation, the sensor is easy and flexible to integrate and can be used “plug & play” in different media. Together with standard system components from Balluff, this makes for an exceptionally economical, complete solution.

Relevant additional information is provided through IO-Link. Functions include, for example, device status monitoring, device temperature or signal quality. This allows you to detect critical changes in the medium, e.g. due to air or particles in the hydraulic system.

Special features

- Economical integration thanks to compact design, standardized system components and interfaces.

- Flexible integration via IO-Link, as analog transmitter or as two-stage switch

- High-performance measurement over the entire measuring range of 0…80 mm: high repeatability of ≤ 100 µm, linearity deviation of ±250 µm, resolution IO-Link 1 µm / analog 12 bit, measuring rate IO-Link 500 Hz / analog 1000 Hz

- High pressure resistance up to 350 bar

- Protection class IP67 and operating temperature 0…85 °C

- Continuous compensation to adapt the measurement to the type, composition and quality of the hydraulic fluid

- Firmware functions to provide additional data for condition monitoring