Collaborating closely with engineers and scientists, skilled optical technicians play a pivotal role in producing many essential modern-day goods such as cameras, consumer electronics, sensors, and solar panels – to name but a few. That’s why the demand for optics professionals is so high. In fact, most Monroe Community College (MCC) Optics students have jobs lined up even before graduating…

Senior Lab technician and lecturer Mike Pomerantz sheds light for us on MCC’s program and explains the key role played by Taylor Hobson Metrology:

Mike elaborates, “The MCC Optical Systems Technology (OST) program is the oldest and largest of its kind in the United States. Our students come through the program with a 1-year certificate or a 2-year associate degree and are immediately ready to add value to any optics manufacturing facility.” He continues “Our faculty and staff have extensive experience in the optics industry and our students, learning from these ‘real-world’ insights, are ready to enter the workforce as educated technicians.”

As our program expands, MCC OST continually updates its equipment and curriculum to keep aligned with Optics industry advancements. This ensures our status as the premier hub for optical technician education and training,” Mike affirms.

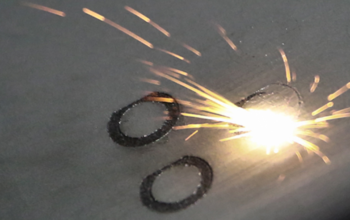

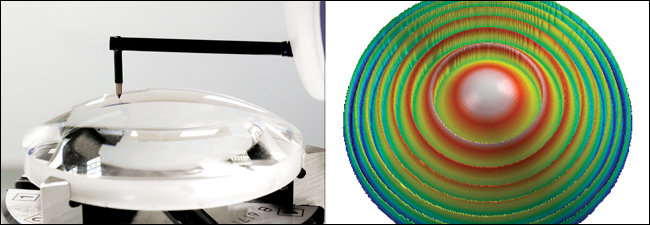

Mike explains in more detail, “Metrology training is a key part of the MCC OST program, and we received our Taylor Hobson PGI Optics profilometer in 2019. The PGI Optics system provides the much-needed precision metrology for measuring the Aspheres that the students produce as part of their advanced manufacturing course (OPT 235). Having a contact profilometer in the classroom provides the students with real-world, hands-on instruction that makes them stronger candidates when they apply for a job. During instruction, many different metrology methods and machine tools are discussed. Once the students begin using the instruments, they build confidence and reinforce good practice. Our mission within the OST program is to expose the students to the equipment they will see in industry. Taylor Hobson Profilometers has always been a standard in precision optics’ manufacturing, and so it was imperative that we included a PGI Optics system in our program”. Taylor Hobson has been a great supporter of the program, providing service and application support when needed. The instrument has been very reliable for us. Even one of our own MCC alumni is working with the Taylor Hobson team – Kenyon has been involved in coming to campus and talking with the students, getting them excited about the opportunities within Taylor Hobson as well as telling his success story after graduating from the program”.

MCC OST also received a visit from Taylor Hobson’s Dr. Jurgen, the co-inventor of the 3D LUPHOScan non-contact profilometer. Mike recalls, “He came to campus to visit our class and provided a very insightful discussion about how LUPHOS was started, and his experience as a technician, engineer, and entrepreneur.”

Mike concludes, “We really appreciate the support that we receive from Taylor Hobson and will be adding more of their equipment to our laboratories as we continue to grow”.

Taylor Hobson has many decades of experience in the manufacture and measurement of precision optics and can offer a wide range of instruments and software solutions for high-value optics applications.

Jamie (Taylor Hobson’s ‘Business Development Director Americas’) sums it up for us, “It’s great to see Mike and other members at MCC OST supporting the next generations of optical fabricators. The knowledge they share is invaluable for the optics industry”. Mike alone has nearly 30 years’ experience at one of the top optics companies in the world, based in Rochester, NY as well as supporting optics programs at MCC OST and UOR (University of Rochester)”.

FORM TALYSURF® PGI OPTICS – A fast, high-accuracy measurement system for precision optics

Our patented PGI (Phase Grating Interferometer) technology enables you to measure large sags with short-length styli for the highest accuracy measurements.

- Easy to program, fast and accurate

- Designed for production environments

- Powerful analysis tools

- Measurement of large sag lenses without compromise

- Automated software routines for repeatable high-accuracy measurements

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.