Little trick for scanning small, very shiny components: thanks to an airbrush, the AESUB yellow scanning spray can reach into even the most delicate grooves or indentations. The 1 µm matting layer ensures optimum scanning results.

To improve the measurement of filigree clockworks, delicate jewelry or tiny microchips, the scanning spray AESUB yellow has been developed for very thin spray coatings.

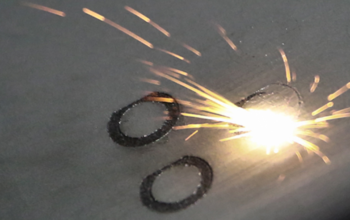

Using an airbrush gun, the very fine spray is applied evenly to the objects. Due to its low viscosity it reaches even the smallest notches and grooves. Within a few seconds, the spray has dried and forms an extremely thin and homogeneous matting layer with a thickness of 0.5 – 1 µm. The matting creates high contrast values on the component surface and thus optimum conditions for optical measurements, which can be carried out over a period of about two hours. After four to six hours, the spray coating has completely evaporated. The component is clean again and can be reused without any problems. “Since the scanning spray evaporates completely, the objects can be sprayed directly in the measuring area,” explains Max Liese, AESUB managing director.

AESUB yellow contains no pigments and is also free of titanium dioxide, which is hazardous to health.

About AESUB:

Scanningspray Vertriebs GmbH (Germany), founded in 2018, has specialised in the development and manufacture of scan sprays. With well-founded knowledge of 3D scanning and aerosol development, AESUB products are continuously improved to allow faster, more efficient and exact 3D scanning processes.

Press/PR for AESUB Scanningsprays

Maren Röding

Technikpresse Maren Röding

Address: Zollstraße 8a, D-21354 Bleckede

e-Mail: m.roeding@technikpresse.de

Phone: +49 15678 748586