| The environment is often the largest contributor to measurement errors. Conversely, once the environment is under control, great strides can be made in improving the overall measurement process. That’s the basic idea behind building a laboratory for dimensional measurement: control the environment to reduce measurement variation and improve agreement with other laboratories.

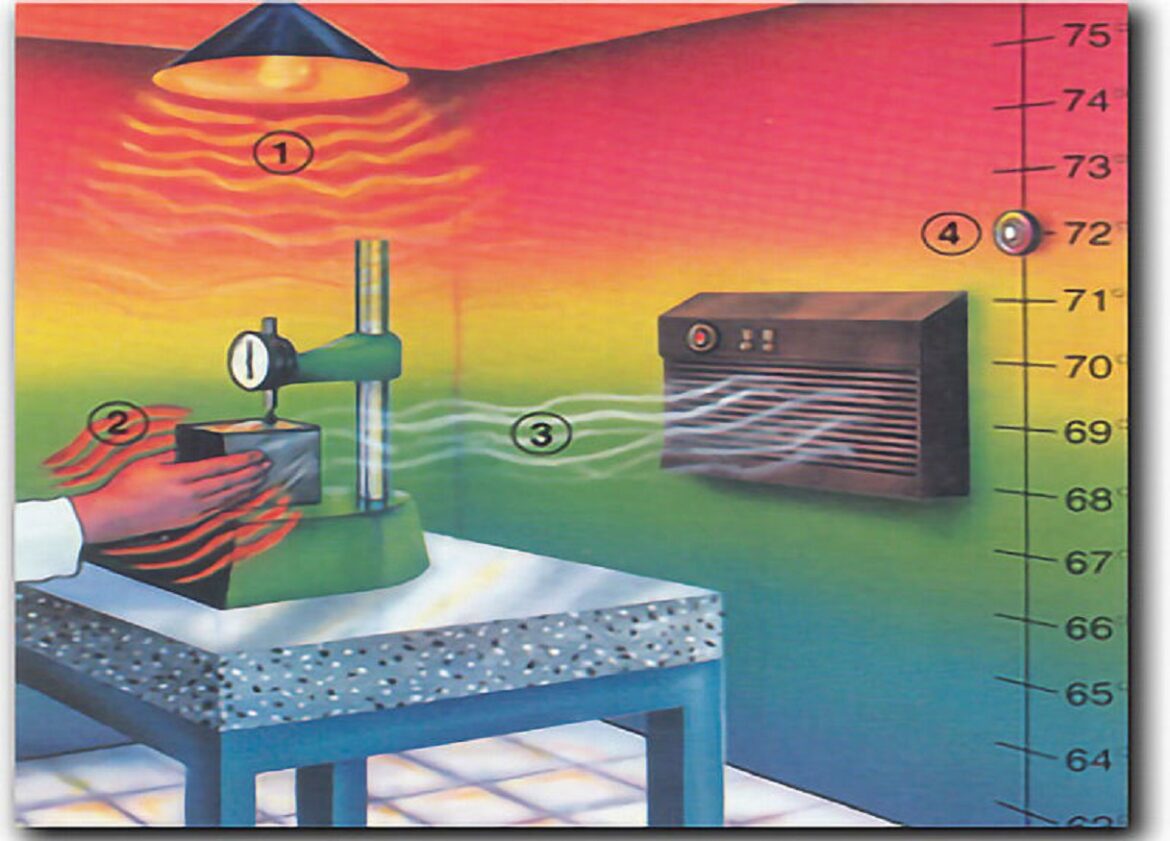

The effort and expense of setting up a controlled environment can vary dramatically. On one extreme you may decide it’s necessary to protect a geometry machine or CMM out on the shop floor from dirt, dust, oil mist and sudden changes in temperature. In this case enclosure will probably provide all the protection you need. On the other hand, if it is necessary to measure gage blocks or other dimensional standards, a lot more sophisticated temperature control would be needed to obtain the desired results. In deciding what you need, the first step is to look at the environmental issues that will influence your measuring process. Get out a piece of paper and jot them down. They probably include sources of heat and cooling, such as radiators, windows, vents, operator body heat, lights, sunlight on walls, and perhaps even cold north walls in the winter. You should also jot down other influences such as vibrations sources and humidity, and even things like barometric pressure if laser interferometers are to be used. Then identify the types of measurements you will likely be doing. Are they short, simple measurements with tight tolerances—things like gage blocks, wires or pins? Or are they more complex—parts over 10 inches using big measuring machines with multiple lengths and diameters, for example, that may take up to an hour to measure. These requirements provide hints as to the environmental controls required. You may already have some type of controlled room in place. Is it good enough and how do you tell? The first thing is to check for thermal stability. This takes a bit of time but it doesn’t require a lot of effort. The thing to do is to check for thermal drift, first over a short period—say a couple of hours—then overnight, and then over a week. The basic test is the same. Set a gage with a reference dimension and check it for repeat. Do this measurement over several 15 minute increments to see if any short-term gage stabilization issues are changing the zero reading. Then start the longer-term drift check. Place the reference in the gage and let it sit there. Manually or automatically record the values over time. If you don’t have a digital gage, set a video camera up to record the hand of the mechanical gage. Your movies may not win any awards for documentaries, but they should be valuable in learning what your temperature control system is doing. You should also be recording the temperature monitor. Compare the gage reading and temperature reading for some often enlightening correlations. When it comes to providing temperature control, the information learned from your needs list comes into play. If you need to do only the basics, a simple on-off temperature control may be enough. On the other hand, mass is an excellent temperature variation compensator. A large mass provides stability despite what may be happening around it. A gage with a large steel base and a large granite or steel plate to rest the sample parts on can help compensate for air temperature changes. Do the stability test, but monitor the air temperature and gage temperature while doing the stability check. You will likely see the air temperature vary a lot, while the gage temperature and reading may change only minimally. But if you’re going to have to go to the extreme of building a top-grade temperature controlled room, it’s no place to cut corners. In fact, the cost of the equipment to control the environment will probably only run about one-tenth the cost of the employees needed to operate the lab over a ten-year span. Of course, this can vary with the size of the lab and the number of people, but people and their associated cost is always going to be the biggest expense. When going the route of a true controlled environment, you need to follow the ABC’s of lab layout. These include: control the temperature around the lab; insulate the lab from the outside environment; prevent sunlight from entering; limit access; think about the type of lighting used and balance the airflow in the room. Most controlled environments use a method that cools the air to a temperature lower than is required, then uses heaters to bring the temperature up to the desired 68 degrees. This type of system is more expensive then an on-off system, but it will control the temperature very precisely. If this is the type of control you need you probably will require a little help from an expert. Companies with demonstrable clean room and temperature control expertise are the ones you would need to talk to. They are experienced with airflow and can work with you to reduce hot or cold spots while making the room comfortable for those doing the work. |