Automation is being embraced by logistics and packaging companies to help them cut waste during product packaging. The amount of vacant space in the box immediately following the customer order’s placement within the box can be used to estimate how much box filler material to need. If it is too much, the package might not close properly, and if there isn’t enough, the product might get damaged.

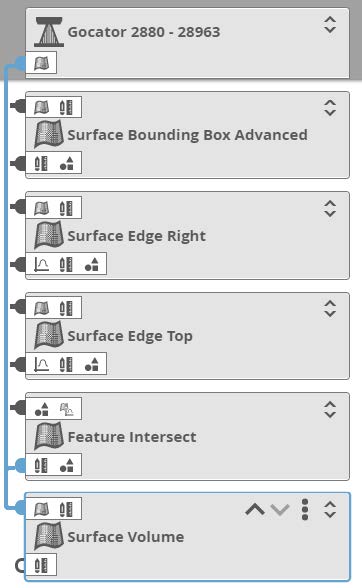

Solution Summary

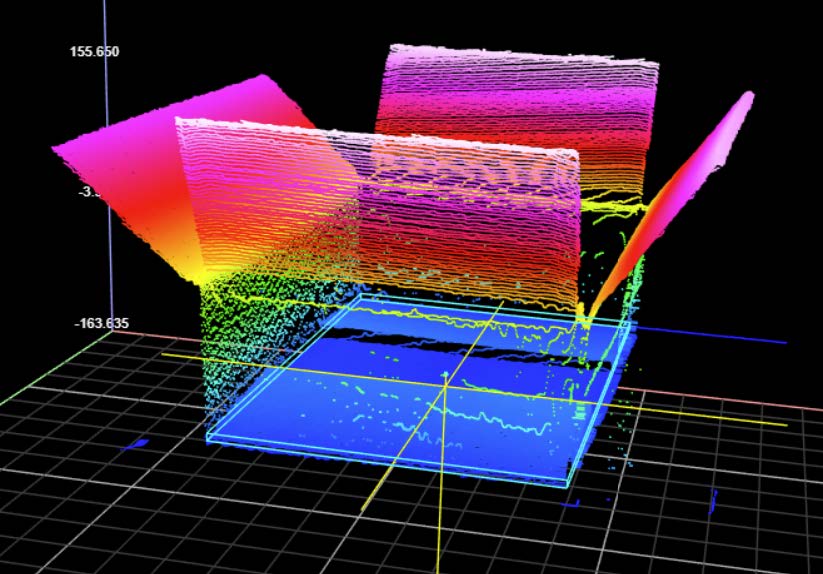

A Gocator 2880 is used to calculate how much empty space is still in the box. Due to its twin-sensor setup, this sensor allows us to see into taller boxes. The Gocator’s surface processing tools are connected to the scan output.

Surface Bounding Box Advanced

The placements of the boxes on the conveyor belt that are passing under the sensor may vary. The Surface Bounding Box Advanced tool is used to locate each box so that other tools can be anchored to it.

Surface Edge

We utilize the Surface Edge tool to find the correct side of the box to ensure the accuracy of our empty space measurement.

Then, we make two perpendicular lines that intersect at the box’s corner using the same tool to identify the box’s upper edge.

Feature Intersect

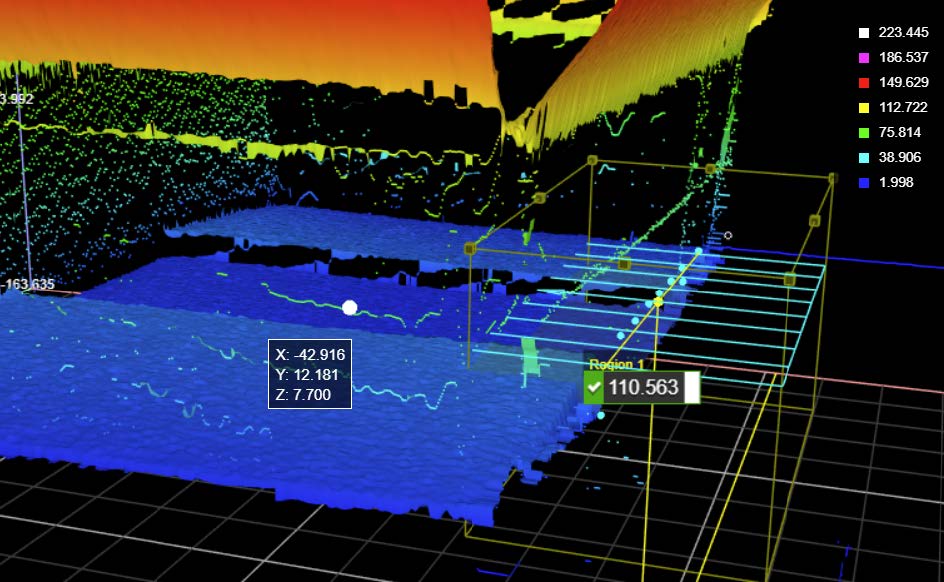

This tool inputs the Surface Edge Right and Topline coordinates and produces an intersecting point that can be used as an anchor.

Surface Volume

The application’s final step is a straightforward volume measurement that uses the coordinates of the Feature intersect as an anchor point. This enables us to generate a precise measurement of the empty space inside the box regardless of where or how it is oriented.

Click on the following link Metrologically Speaking to read more such blogs on Metrology.