The company’s objective is to examine the geometric stability of specific railway security features, including the chassis and body of a vehicle or an engine.

Even a large-scale measuring arm gives highly accurate measurements with a precision that is far greater than the inspection tolerances.

When evaluating railway bogies, a measuring arm is not typically the tool of choice. Traditional jigs and calibrated test benches are utilized as an alternative. The Ace measuring arm can be attached to any sort of trolley, unlike these specially built seats. Therefore, a single measuring arm can replace several conventional jigs and offer greater measurement precision and reliability.

Due to the flexibility and convenience of the use of the Kreon measuring arm, Traction&Services is currently looking into the prospect of offering measurement services off-site. This was not a possibility with the prior hefty and large jigs.

The Kreon Ace measuring arm’s adaptability enables the business to expand the range of measurement services it offers. In order to assess any potential structural deformation, dimensional examinations of damaged carriages have been performed by measuring the flatness, alignment, and perpendicularity of various surfaces. The business also intends to use the Ace measuring arm for internal tasks including inspecting current control tools like jigs and gauges.

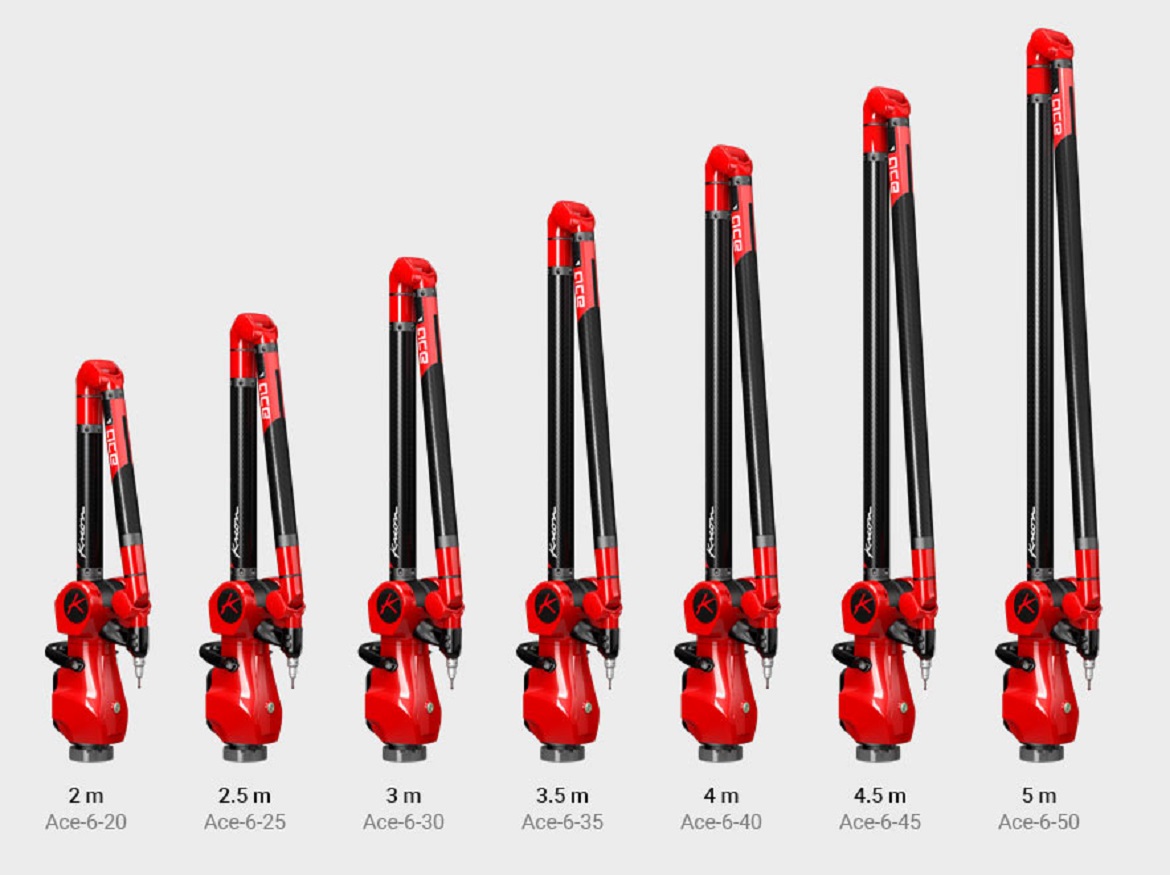

The KREON ACE 7 axis 4.5m measuring arm with the probe is suitable for the following applications, in conjunction with the Polyworks software:

- Inspections using probes on bogies, casings, trolleys, and components

- Generating measurement and conformity reports

- Inspection of existing control tools, such as jigs and gauges

- Possibility to carry out measurement services off-site

Before carrying out any specific operations the measuring system has never been used for before, such as verifying alignment and perpendicularity on damaged cars, a feasibility analysis is carried out. The customer is then given access to a technical dossier, which is used to create the proper measurement range in the Polyworks program.

The company has found Polyworks to be a highly useful tool, especially in terms of its capacity to direct the operator and reduce errors. Additionally, producing and understanding clear reports is simple, which cuts down on the time needed for control process execution.

Traction&Service is really happy with the measurement tools and the assistance it has gotten from Kreon. The availability of the Kreon experts and their analytic skills allowed for the greatest possible product customization to meet the needs.

Click on the following link Metrologically Speaking to read more such case studies about the Metrology Industry.