This news has been reproduced from Renishaw’s website. The link to this news is given below :

https://www.renishaw.com/en/alignment-laser-accelerates-machine-tool-assembly-checks–45588

The ultimate accuracy and reliability of a machine tool depends in no small degree on the alignment checking during its assembly. For machine tools produced in high volumes, the efficiency of the alignment checking process is paramount. Seeking an alternative to traditional error measurement techniques, Hurco Manufacturing Ltd. (Hurco) chose Renishaw’s XK10 alignment laser system to increase both precision and throughput.

Background

A true pioneer in the application of computer technologies in machine tool design, Hurco is a global provider of CNC machines. Founded in Indiana, USA in 1968, the company manufactures a comprehensive range of products including 5-axis CNC machines, multi-axis CNC lathes, vertical machining centres and turning centres.

Its worldwide customer base comprises precision tool, die and mold manufacturers, independent job shops, specialised short-run production manufacturing companies and OEMs of metal fabrication tools. The company’s product portfolio includes three well-known brands: Hurco, Milltronics and Takumi.

Hurco Manufacturing was established in Taiwan in 1999 and is today responsible for the manufacture and assembly of the complete range of Hurco machine tools. To ensure requirements for machine tool precision, safety and reliability are met, strict quality control is paramount for each step in the manufacturing process.

Hurco and Renishaw team members

Challenge

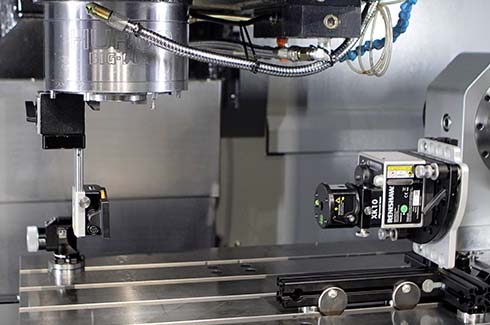

Hurco using XK10 alignment laser system

With Hurco producing more than 2,000 machine tools every year, increasing measurement efficiency was a vital driver for the company’s inspection and verification processes. Not only did machine measurement and alignment need to be highly accurate, it also needed to be faster.

Alignment inspections during the assembly process were carried out by Hurco using a blend of traditional measurement tools, CMMs and state-of-the-art calibration equipment. The company had long employed a range of Renishaw solutions, including the XL-80 laser interferometer, QC20-W ballbar system and XR20-W rotary axis calibrator.

The sheer size and scale of cast machine tool components presented significant restrictions for CMM solutions, while the inherent weaknesses of traditional measurement techniques risked limiting operational performance. Wang Shun-Chien, Vice President of Hurco Manufacturing explained: “In the past, we have measured and aligned our cast products using coordinate-measuring machinery, but the larger dimensions of cast parts were always a limiting factor, and made it rather labour intensive.”

He continued, “We would also use traditional error checking tools like granite squares, dial gauges and autocollimators during the assembly process, but these were never efficient enough, and the measurement results were too inconsistent.”

“When we needed to measure the parallelism of some large cast parts, if the granite square and guide rail are a distance away, then the dial gauge needed to be extended to reach the granite, which would then cause any deviation result to amplify.”

Hurco set itself the task of identifying a more accurate machine tool alignment solution. One which was much less time and labour-intensive to set up and use, and which could replace the traditional measurement methods.

Solution

Following extensive research and testing, Hurco chose to adopt Renishaw’s XK10 alignment laser system. The XK10 can be applied to linear rails to ensure they are straight, square, flat, parallel and level, as well as to spindles and chucks to assess direction and coaxiality of rotary machines.

An all-in-one digital measurement solution suitable for a range of different CNC machine tools, the XK10 comprises a launch unit for primary laser transmission; wireless transmitter and receiver units; a portable display unit and a fixturing kit. An additional XK parallelism kit carries out parallelism measurements.

The XK10’s compact size, wireless connectivity and versatile fixturing means that it can be used in many different configurations, enabling detection and measurement of both geometric and rotational errors across all types and sizes of machine tool.

The display unit enables the operator to collect, analyse and record measurement data. It provides step-by-step instructions for each type of measurement, with intuitive graphics and real-time readings guiding the operator through each stage of the measurement process.

Unlike an autocollimator, which depends on the principle of converting angular measurements into linear measurements, the XK10 alignment laser system takes linear measurements directly, thereby removing the inherent conversion error. Importantly, breaking the XK10’s laser beam during data capture does not require a complete restart, unlike with a laser interferometer solution.

By replacing various sizes of granite squares, the XK10 has also solved the problem of limited storage space and logistics. Thanks to its portability and flexibility, it is easy to take to site, performing precision measurements in real time.

Hurco Manufacturing Ltd. (Taiwan)

XK10 all-in-one digital measurement solution

XK10’s display unit to collect, analyse and record measurement data

Results

The XK10 alignment laser system succeeded in significantly reducing the amount of time Hurco needed to implement high-accuracy machine tool alignment. After testing the XK10 system repeatedly, they found that it provided a solution that is genuinely capable of replacing traditional methods.

Mr Wang said, “As a conservative estimate, I’d say that Renishaw’s XK10 alignment laser system has at least doubled our overall measurement efficiency, and our evaluation process has proven that the measurement results tally precisely with those from high-precision coordinate measuring machines.”

With a generous measurement range of 30 m the XK10 handles the requirements of many large machine tools. Negotiating the span between guide rails for parallelism measurements has become easy, removing the need for large granite squares and avoiding the deviation risk of hyper-extended dial gauges.

Mr Wang continued, “The XK10 has particularly impressed us in terms of the parallelism measurement between two measurement rails. Compared to autocollimators, setting up the XK10 for multiple rail measurements is much simpler. We align the laser unit and turn the laser beams through 90° with the XK parallelism kit. The system then automatically analyses the data collected and provides us with measurements of the parallelism between the two rails. It couldn’t be easier.”

“By replacing various sizes of granite squares, the XK10 has also solved the problem of limited storage space and logistics. Thanks to its portability and flexibility, it is easy to take to site, performing precision measurements in real time. It is used for machine tool assembly, calibration and maintenance, and by enabling better understanding of the status of each CNC machine, resources can be allocated more effectively.”

Mr Wang added, “The reports that the XK10 produce are also highly intuitive, and through a choice of tables or charts, clients can very quickly determine the status of a machine tool during an acceptance inspection.”

“Now that we have the XK10, we can quickly ascertain whether the source of deviation is connected to the assembly process, rather than workpiece machining or cast part rigidity. And if we discover issues with the precision of the workpiece machining, we can rapidly respond by checking the CNC machines and performing any necessary adjustments. It has really helped us to drive up efficiency.”

Since it was first founded, Hurco has used virtually all of Renishaw’s calibration products, including the XL-80 laser interferometer, QC20-W ballbar system and XR20-W rotary axis calibrator. Mr Wang explained: “The addition of the XK10 has made our arsenal of measurement instruments even more comprehensive, giving us dedicated instruments for machine tool assembly, calibration and maintenance. It also allows us to gain a better understanding of the status of each CNC machine so that we can allocate resources more flexibly.”