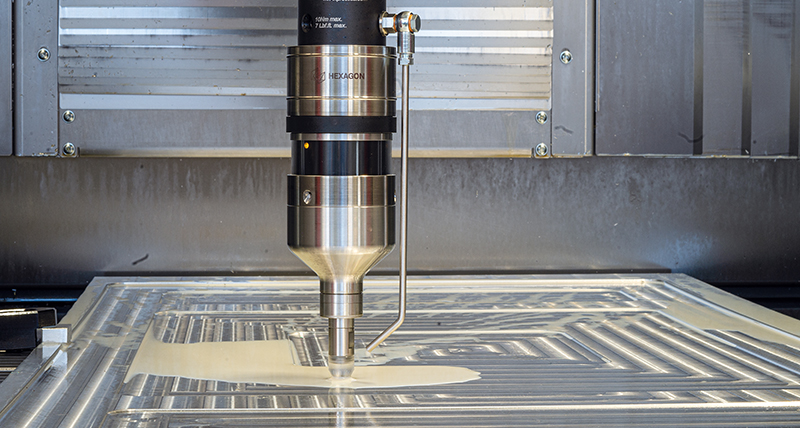

Hexagon’s Manufacturing Intelligence division has enhanced its ground-breaking ultrasonic probe for automated wall thickness measurement on machine tools with the launch of two new versions

Category: MS Blog

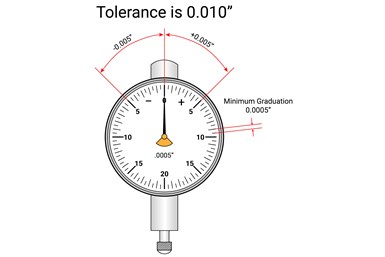

How to Choose the Right Dial Indicator

The article has been originally written by :- GEORGE SCHUETZ Director of Precision Gages, Mahr Inc. Digital alternatives are replacing dial indicators – but dial indicators can

How do I Calculate TUR?

This article is originally written by Henry Zumbrun, President, Morehouse Instrument Company. This article was published as a blog at https://mhforce.com/how-to-calculate-tur/ on Dec. 13, 2021.

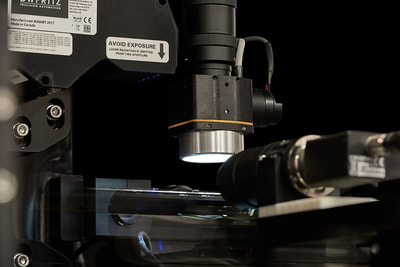

3 Key Benefits of an Automated Non-Contact Metrology System

In the precise world of high volume manufacturing (HVM), microns and milliseconds matter when inspecting medical staples, fitness trackers and smartphones to meet either government

Consumer Goods Inspection and Hybrid AI

Quality inspection of consumer goods ensures products meet specifications, brand criteria for appearance, and mandatory standards for packaging, labeling, and instructions. With increasing consumer demand

The future of metrology

The below article has been directly reproduced as it is for our audience. The below link corresponds to the original article :- “https://www.npl.co.uk/foresighting/metrology” Accurate measurement

GD&T’s New Rule and What it means for Measurement

“This article has been written by Mark Malburg, A. J. Mennuti and Mike Zecchino. It originally appeared in Quality Magazine, May 6, 2021.” Here we

Eleven Benefits of the Cloud for Calibration Management Software Systems

Software as a service can help reduce costs and provide a more robust platform The National Institute of Standards and Technology (NIST) was directed by

ISO 10360-10:2021 Offers Simplified Process for Interim Field Test of Laser Trackers

Brunson’s KinAiry Solution Adapts to New ISO Procedure Kansas City, Missouri, USA – With the release of ISO 10360-10:2021, laser tracker end-users can now test

Additive Manufacturing — New Frontiers for Production and Validation

Today, additive manufacturing (AM) is dramatically changing the way that manufacturers produce end-use parts and components. Not surprisingly, analysis of the accuracy and repeatable tolerance