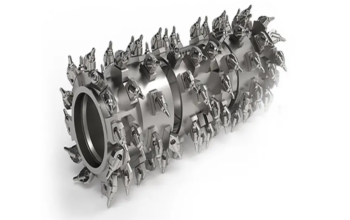

The manufacturing and forging industries rely heavily on the efficiency and precision of the tools used in the production process. Among these tools, forging dies plays a vital role. These dies are also prone to wear and tear during the production process, making repairing them a severe problem. This case describes a new approach to forging die repair that combines the 3D scanner with the industrial robot to improve the efficiency and precision of die repair.

Traditional Forging Die Repair Method

Traditional forging die repair is mainly done by manual overlay welding and machining. The manual overlay welding process is time-consuming and requires highly skilled welders to achieve accuracy. The subsequent machining stage involves the removal of excess material, which further adds to the time and cost. This traditional method is not only costly but also prone to inconsistencies that affect the overall quality of the dies.

3D Scanners & Industrial Robots: Automating Die Repair

The integration of 3D scanners and industrial robots has become a more efficient solution than traditional repair methods. 3D scanning technology creates highly accurate 3D models of damaged molds, which can be seamlessly converted into robotic operating paths for precise and automated overlay welding.

The repair process begins with obtaining a 3D model of the damaged dolly, a step that is essential to ensure that every contour, groove and defect is accurately documented. The equipment used in this case was a SHINING 3D FreeScan Combo metrology 3D scanner, which offers three crucial advantages in forging dies repair applications:

● High Precision: With an accuracy of up to 0.02mm and stable repeatability, the FreeScan Combo is able to provide accurate data for subsequent repairs.

● Fast Scan Speed: The FreeScan Combo scans at up to 1,860,000 points/s, and with the software algorithms, scans are fast and smooth.

● Multiple Scan Modes: The FreeScan Combo is equipped with four working modes: multiple lines scanning, single line scanning, fine scanning, and infrared scanning. It can easily cope with a wide range of molds of various sizes, materials and features.

After obtaining an accurate 3D model, it is often necessary to import it into programming software to create a robot program that defines the weld path and sequence of operations. The robot is equipped with a welding tool that can accurately deposit material onto the damaged mold in a predetermined path, enabling automated overlay welding. Automated overlay welding is not only highly accurate but also much faster than manual overlay welding, reducing overall repair time.

Conclusion

The SHINING 3D FreeScan Combo Scanner, in combination with industrial robots, has ushered in a new era of efficiency and precision in forging dies repair. By automating the overlay welding process and eliminating the need for manual cladding and machining, the system significantly reduces repair time, labor costs, and material waste.

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.