When it comes to obtaining accurate measurement data, coordinate measurement machines are regarded as the gold standard. The values produced by a CMM are often trusted by everyone. Yet, integrating the capabilities of CMM machines with Laser Measurement Systems can result in hybrid solutions that speed up measurement, increase throughput, and save costs.

What is a CMM?

A CMM, or coordinate measurement machine, is a machine that collects data from the geometry of a solid part on the X, Y, and Z axes using delicate touch sensors. To assess whether the part’s dimensions comply with design criteria, metrology software processes the coordinates of those points, typically from CAD drawings.

Sensors can be placed over and around items using CMMs’ huge worktables with gantry, bridge, cantilever, or horizontal arm constructions. Sensors frequently use extremely precise electronic touch probes, although they can also use non-contact measurement techniques.

What is a Laser Scanner?

Non-contact measurement tools called 3D laser scanners employ laser light to record data points on a part’s surface. The digital 3D models made from the data points are then compared to the manufacturer’s specifications.

Devices for 3D laser scanning come in a wide variety of shapes and sizes, both mobile and fixed. Also, they measure with varied degrees of precision, from consumer-level standards to metrology-grade requirements.

CMM Machines vs. Laser Measurement Systems

CMM machines are renowned for taking measurements that are incredibly accurate down to sub-micron levels. When writing measurement routines to match part requirements, they allow a great deal of freedom. Nevertheless, 3D laser measuring systems can collect tens of thousands or even millions of data points in a fraction of the time as compared to CMMs, which may only collect a few hundred points every routine. Laser scanners can produce 3D models of the complete part, but CMMs are typically used for targeted inspection of specific parts of the part.

Moreover, CMM measuring procedures can take a lot of time. If a CMM is not designed to record regions of the part that are presumed to be compliant before measurement, issues may occur. And finally, for some materials and complex part forms, CMM measurement is just not the best option.

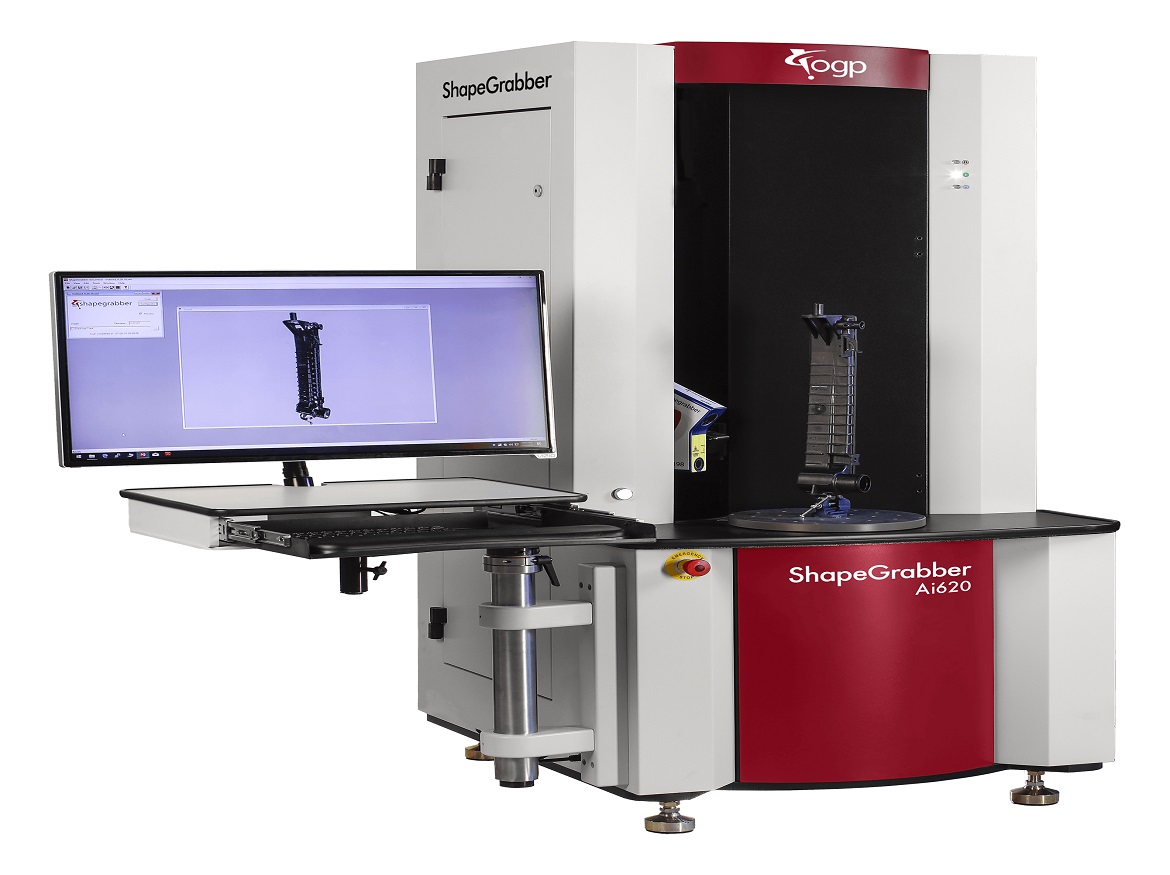

3 Advantages of ShapeGrabber 3D Laser Systems

OGP ShapeGrabber Automated 3D Laser Scanning Systems are metrology-class 3D scanners that employ highly accurate scanheads to accurately and swiftly measure intricately formed items. ShapeGrabber scanheads simultaneously collect lines of coordinate data points, as opposed to CMM probing, which only records data points one at a time. More than 1.5 million data points can be captured each second. The three additional advantages of the OGP ShapeGrabber are as follows:

- Because ShapeGrabber systems are automated, they do not require software alignment or registration. The part can be put on the rotating stage and the scan starts with a click on the interface by operators with a variety of skill sets.

- With a wide range of materials, hues, and finishes, ShapeGrabber systems are perfect for measuring complex objects like molded plastics, castings, stampings, and 3D-printed items.

- Part locations that CMM processes may have missed can frequently be scanned by ShapeGrabber systems.

While ShapeGrabber 3D laser scanners continue to advance and get close to the capabilities of CMMs, physical probes still hold an advantage when it comes to accuracy.

Combining Benefits of CMMs and ShapeGrabber 3D Laser Scanners

In general, manufactured parts will have a wide range of characteristics and tolerances. The tightest tolerance on the drawing is frequently what quality inspectors use to determine whether a CMM is necessary. Unfortunately, using a CMM for 100% of feature inspection results in extremely time-consuming inspection procedures that reduce throughput.

The most effective method for boosting throughput is a hybrid approach, according to OGP’s experience working with hundreds of customers to install laser scanning measuring solutions in recent years. This entails utilizing the best instrument for the measurement task at hand and leveraging the advantages of both CMMs and laser scanners.

Capture Measurement Data Quickly

ShapeGrabber scanners quickly verify the identical parts being measured on a CMM in hybrid setups. The employment of both instruments together can maximize throughput while enhancing measurement efficiency by allowing the CMM to be focused on those most rigorous requirements, even while the laser scanner may not be able to match the high accuracy needs of the tightest tolerances.

The 4-Step Hybrid Measurement Approach

In practice, this means first checking the part that needs to be measured with the ShapeGrabber system.

- Prior to commencing the CMM procedure, scan the part with ShapeGrabber.

- Examine the outcomes. The study using a 3D scanner gives an immediate response on the majority of dimensions and gives a general impression of the part in comparison to the nominal design.

- Send the part to the CMM for measurement of the remaining important features only if the initial inspection is successful.

- If the laser scanner inspection of the part is unsuccessful, the part stops, and no CMM time is lost.

Using Coordinate Measuring Machines + Laser Measurement Machines Saves Time and Money

Although combining two processes rather than one to save time may seem counterintuitive, we have seen overall part inspection durations decrease by more than 60% when using this hybrid technique. Customers claim that by discovering faults at the scanning stage in sections of the part that would typically be ignored by CMM algorithms, they may avoid sending defective parts.

Both coordinate measuring machines and three-dimensional laser scanners are effective metrology tools, although they each have specific advantages and restrictions. By combining them in hybrid ways, you may take advantage of their finest qualities to speed up inspections, cut down on measuring time, and save money. Allow your local OGP Representative to collaborate with you on the design and implementation of a hybrid measuring solution that incorporates the advantages of both your CMM devices and the ShapeGrabber Automated 3D Laser Scanning Systems.

Click on the following link Metrologically Speaking to read more such blogs on Metrology.