Enhancing Glass Welding Quality with Precitec’s CHRocodile 2 S Chromatic Line Sensor

In the realm of glass welding processes, achieving the desired level of quality hinges on a crucial factor: the accurate measurement of air gaps between glass sheets. Addressing this need with precision and efficiency, Precitec introduces the CHRocodile 2 S chromatic line sensor. Through its innovative interferometric technology, this sensor not only measures air gaps as minute as 2 µ (micrometre’s), but also gauges the thickness of glass sheets up to 55 mm. With an impressive measurement speed of up to 66 kHz, the CHRocodile 2 S emerges as the optimal solution for time-sensitive inline inspections, accommodating air gaps of varying sizes between two glass sheets. Its versatile capabilities position it as a reliable choice for quality control applications across a spectrum of production environments.

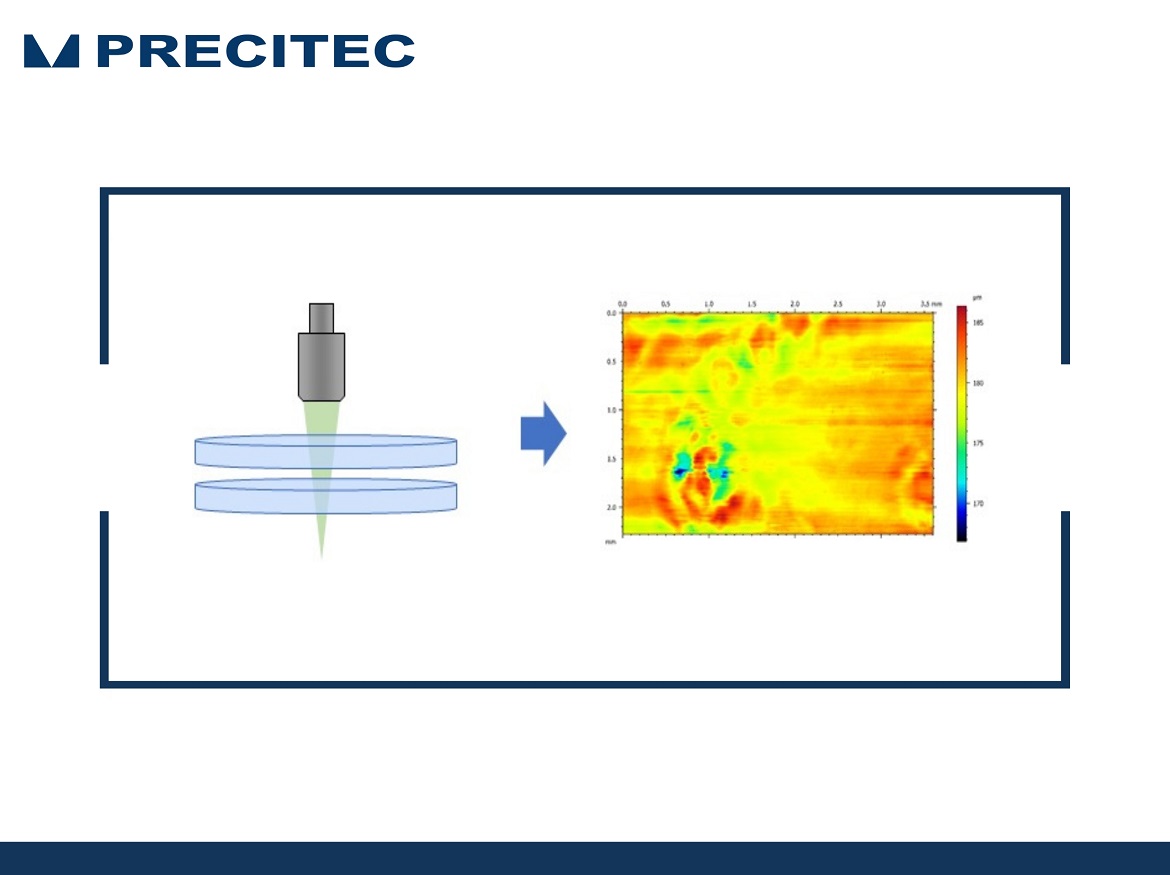

The CHRocodile 2 S’s use of interferometric technology marks a breakthrough in glass welding quality assessment. The system operates on the principle of utilizing light interference to measure distances with exceptional accuracy. By emitting a light beam onto the surface of the glass and analyzing the reflections, the sensor derives precise measurements of air gaps between the glass sheets. This ensures that even the tiniest gaps of 2 µ do not go unnoticed, contributing significantly to the overall structural integrity and aesthetic appeal of the final product.

One of the standout features of the CHRocodile 2 S is its capacity to measure glass sheet thickness, a vital parameter in the welding process. The sensor’s proficiency in measuring glass thickness up to 55 mm provides manufacturers with a comprehensive view of the material’s dimensions. This capability aids in identifying irregularities and inconsistencies that might compromise the welding process, allowing for swift corrective actions and an enhanced end product.

In manufacturing environments where speed and precision are of the essence, the CHRocodile 2 S shines. Its remarkable measurement speed of up to 66 kHz empowers real-time, inline inspections of air gaps, ensuring that any variations are promptly detected and addressed. This characteristic is particularly beneficial for industries that demand efficient quality control processes, preventing defects and minimizing wastage.

The adaptability of the CHRocodile 2 S further amplifies its value. Its all-rounder qualities make it an ideal fit for diverse quality control applications across various production settings. Whether it’s the automotive, construction, or electronics sector, the sensor seamlessly integrates into different workflows, bolstering the reliability of the end products and streamlining the quality assurance process.

In conclusion, the CHRocodile 2 S chromatic line sensor from Precitec emerges as a game-changer in the domain of glass welding quality control. Through its employment of advanced interferometric technology, it deftly measures air gaps as small as 2 µ and gauges the thickness of glass sheets up to 55 mm. The sensor’s impressive measurement speed, coupled with its versatility, renders it a sought-after tool for inline inspections in industries that prioritize precision and efficiency. By ensuring the integrity of glass welding processes, the CHRocodile 2 S contributes to the creation of impeccable end products while optimizing production workflows.

Want to know more about their solutions for the glass industry then contact their team in India Karthik Boinapally: K.Boinapally@precitec.com or Suraj Dhanraj Jadhav: D.Suraj@precitec.com