Nordson TEST & INSPECTION announced its participation in SEMICON Taiwan, one of the most anticipated events in the semiconductor industry. The company will be showcasing its state-of-the-art inspection and metrology solutions, including the CyberOptics SQ3000™+ Multi-Function system, the new Quadra 7 Pro Manual X-ray Inspection (MXI) System, and the revolutionaryWaferSense® Auto Teaching System™(ATS2) . The event will take place from Sept. 6-8, 2023 at TaiNEX 1&2 in Taipei.

The new Quadra 7 Pro MXI system sets a new standard for 3D/2D manual inspection in back-end semiconductor applications. Powered by the revolutionary Onyx® detector technology, it delivers exceptional image clarity and reduced noise levels, elevating the inspection experience to new levels of precision and efficiency.

Equipped with the latest Dual Mode Quadra NT4® tube, the Quadra 7 Pro provides users with maximum flexibility. This innovative feature offers brightness and resolution modes, allowing operators to dynamically switch between them based on specific application requirements.

Enhancing the Quadra 7 Pro’s capabilities is the newly developed Revalution™ software, tailored specifically for high-end semiconductor applications. With an intuitive interface, optimized workflow, and expanded functionality, Revalution™ software empowers operators to efficiently analyze and interpret inspection data, contributing to faster decision-making and improved overall productivity.

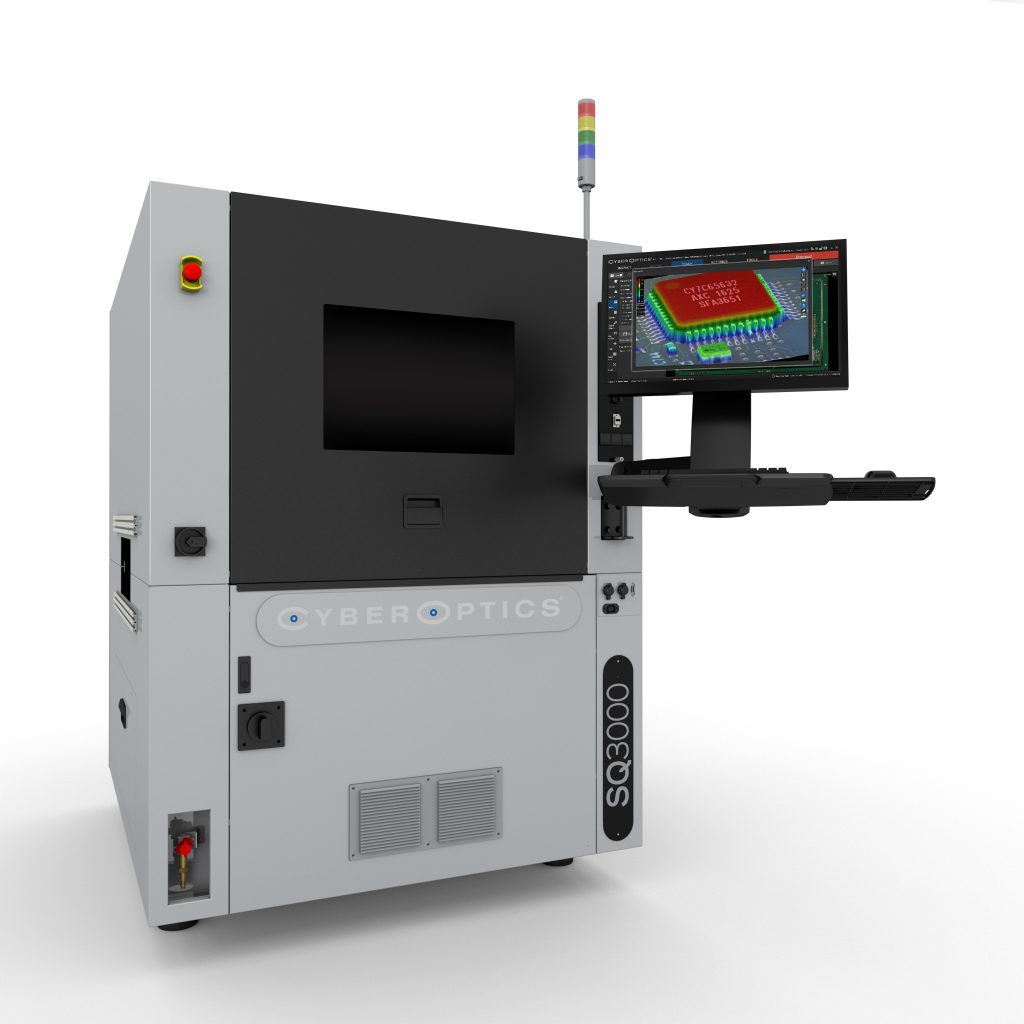

The CyberOptics SQ3000™+ Multi-Function system for AOI, SPI, and CMM is designed for high-end applications, including advanced packaging, mini-LED, advanced SMT, and 008004/0201 SPI. This all-in-one solution offers unmatched accuracy and high speed, utilizing an even higher resolution Multi-Reflection Suppression® (MRS®) sensor that effectively eliminates reflection-based distortions caused by shiny components and specular surfaces.

The WaferSense® Auto Teaching System™ (ATS2) is a multi-camera sensor that, when used in conjunction with CyberSpectrum™ software, enables accurate wafer hand-off calibration for semiconductor tool alignment and setup for front-end semiconductor fab environments. With the ability to capture three-dimensional offset data (x, y, and z) in real time, ATS2 simplifies wafer position teaching without the need to open the tools. This results in repeatable and reproducible setups, streamlined maintenance checks, accelerated troubleshooting, and reduced technician-to-technician variation, leading to significant yield improvements and enhanced productivity for semiconductor fabs worldwide.

To witness the future of advanced inspection and metrology technology, visit booth #L0800 on the 4th floor at SEMICON Taiwan 2023, and explore Nordson TEST & INSPECTION’s range of industry-leading solutions.

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.