Marposs OptoCloud EDU (Electric Drive Unit) is the latest generation of 3D precision inspection solutions, designed for the Electrical Vehicle Industry and its unprecedented quality assurance processes.

OptoCloud EDU is capable of reconstructing the 3D model of complex and articulated workpieces and automatically executing measurements and vision inspection tasks.

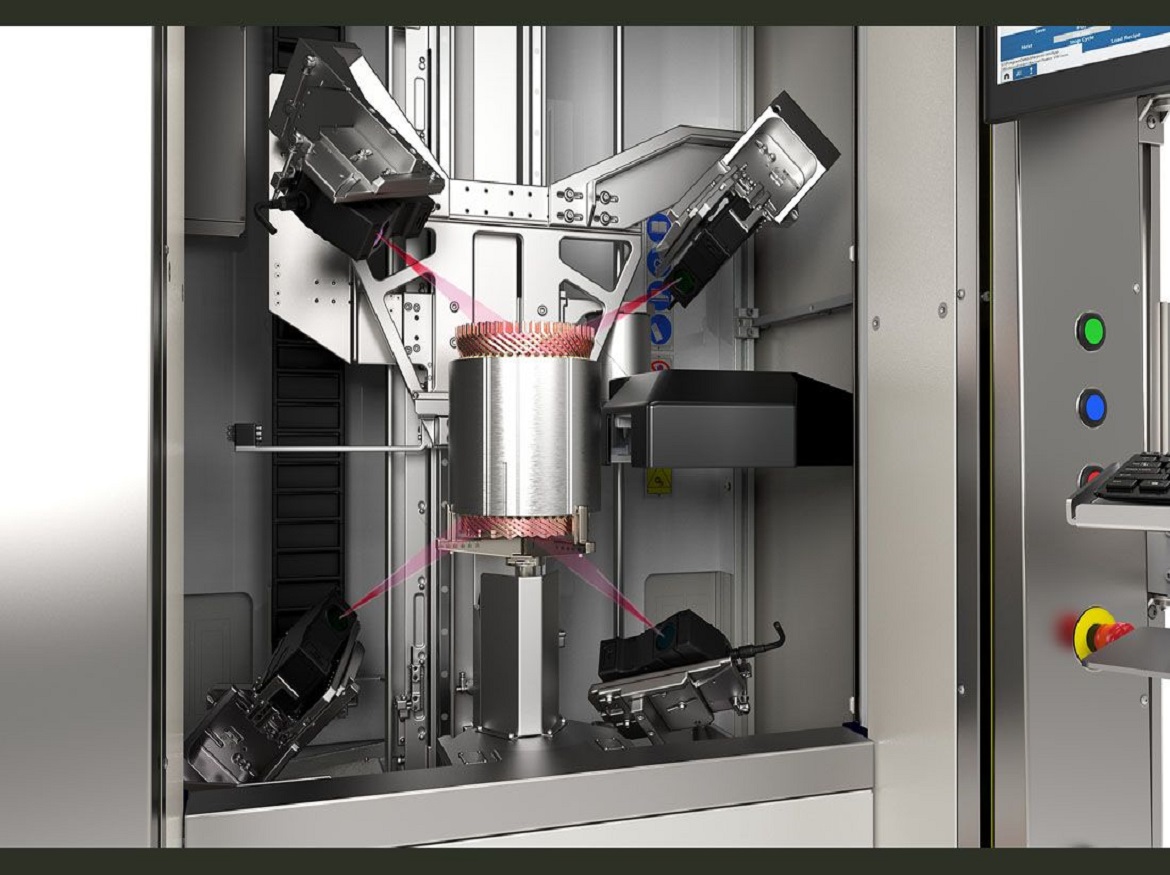

The 3D reconstruction of complex and structured surfaces is operated through multiple laser heads, which generate the Point Cloud of the part, while the workpiece is quickly rotated by 360°. The Point Clouds is acquired by the different laser heads – taking advantage of spatial diversification – and then combined into a single 3D reconstruction. As the final step, Marposs software elaborates the dataset and executes the requested measurements and vision inspection tasks.

SUPER-FAST AND PRECISE

The OptoCloud EDU resolves what is demanding or even impossible for traditional contact measurement machines in less than a minute.

For instance, OptoCloud EDU can fully validate 240 electrical contacts of a motor stator in just 30 seconds! Isn’t it 100 times faster than a traditional contact 3D system?

OptoCloud EDU is so fast that has become a perfect solution for quality control at the production line, both with manual and robot loading.

Also, the inspection results by the line operator are fast and intuitive: the 3D reconstruction, the inspection overlay over the 3D visualization, and the interactive navigation allow easy operator review in a few seconds.

SUPER-EASE-OF-USE, THANKS TO ITS 3D VISUALIZATIONS OF THE WORKPIECE

OptoCloud EDU is powered by an effective software suite, capable of elaborating the Point Cloud into a 3D reconstruction and – as the last step – into an intuitive graphical representation. Line operators can easily review – by images – the result of the automatic inspection and navigate up to the desired level of detail. Perfect for quality control, but not only. The multiple lasers in the OptoCloud EDU generate a Point Cloud with a very high level of spatial resolution, incorporating details that are a powerful dataset for design reviews and final project validation.

Moreover, OptoCloud EDU is designed for fast and easy part handling: part loading and unloading operations can be critical, but not for the OptoCloud EDU. Thanks to the Z-axis, the laser heads are automatically moved out from the handling area, leaving large space for the workpiece handling and removing the risk of sensor damage by handling mistakes.

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.