In today’s world, 3D technologies are frequently applied in the automotive sector. In addition to being employed in automotive design, 3D scanners are also used to tune and repair vehicles. Formerly, automotive design was solely done by hand, therefore the new technology has become a true advancement. However, even slight calculation errors severely damaged the vehicle’s look and harmed its aerodynamics.

Only if precise calculations are made are design flaws avoidable. With the 3D scanner, you can complete this crucial task automatically. Professionals in the automotive sector now depend on 3D scanning more than ever since technology makes it possible to design parts with the highest degree of precision and quickly resolve challenging issues.

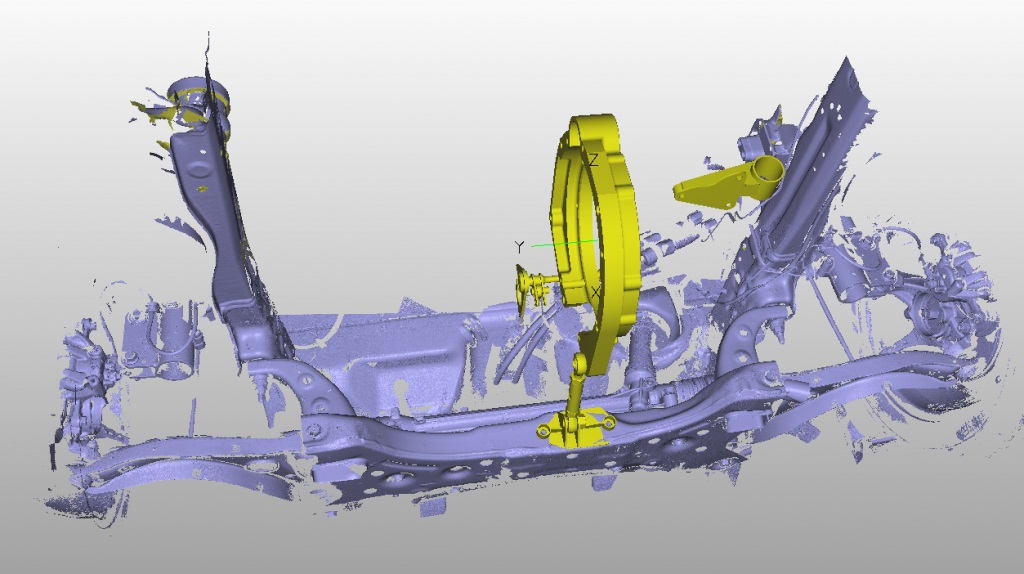

The high-precision geometry of the KIA RIO front suspension was required by NRing specialists who work on, maintain, and prepare vehicles for any Russian racing series’ specifications. The use of 3D scanning technology is the best remedy for this issue.

RangeVision professionals were chosen to handle the scanning of the running gear because as both a 3D scanner manufacturer and software developer, they are well-versed in all aspects of 3D scanning.

Professionals have access to a wide range of options thanks to 3D scanning technology from RangeVision, including the following:

- speed up the process of manufacturing, repairing, or tuning a car;

- achieve a high level of accuracy;

- improve work efficiency;

- reduce the cost of the service;

- visualize the project.

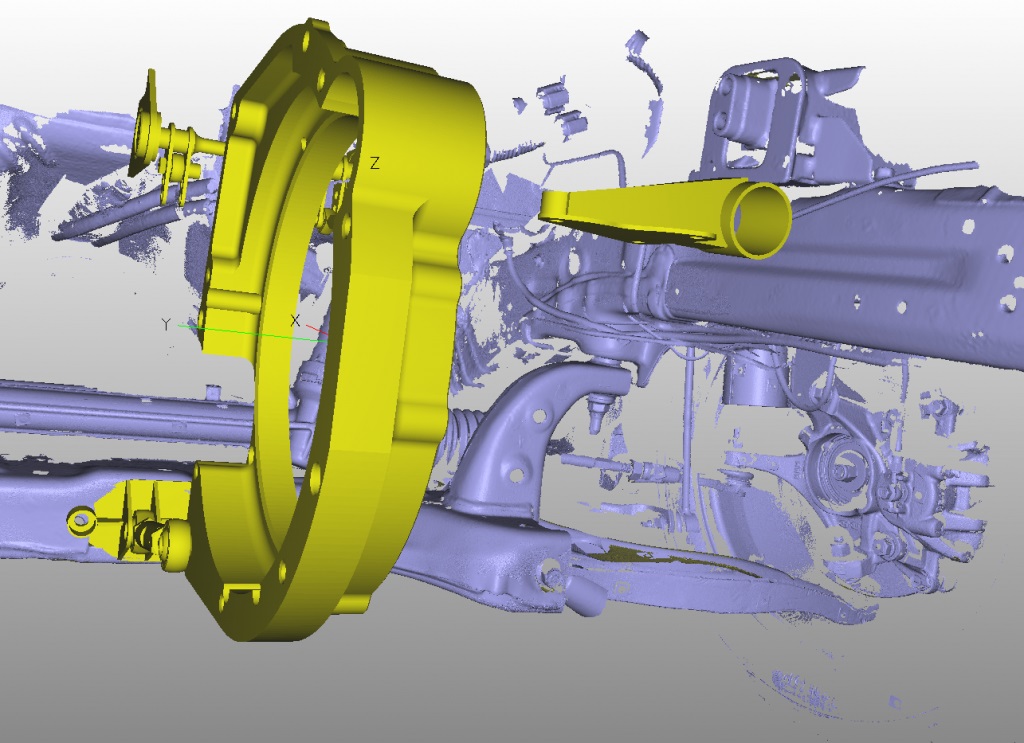

The customer required the original chassis surface and engine attachment points so that mounting brackets for a redesigned gearbox could be measured and designed. A RangeVision expert with the relevant tools went to the NRing service after the terms and the extent of the work was agreed upon.

RangeVision PRO, an industrial 3D scanner, was used to digitize the vehicle geometry. Within a day, the STL format of the scan result, which had a high volumetric accuracy of less than 0.2 mm, was generated and sent to the customer.

The captured suspension geometry was placed in the coordinate system of the customer-provided 3D model in order to optimize the design of the brackets securing the upgraded gearbox.

In order to update and get the car ready for racing contests, a lot of hard work and time has been put into 3D scanning.

You can accomplish the very precise design of auto parts with a sophisticated 3D scanner like RangeVision PRO. You can obtain a high-resolution digital version in STL format, including the little components, using a 3D scanner. You may observe the outcome in great detail and, if necessary, perform more measurements, virtual tests, and design calculations without incurring additional costs in terms of money or time thanks to the computer model of the parts and its visual presentation. The best parts possible were obtained as a result of the process, fully satisfying the needs of equipment specialists for maintenance and modification.

Click on the following link Metrologically Speaking to read more such blogs on Metrology.