What Is Reverse Engineering?

The act of dissecting a physical thing to determine how it functions and developing a digital representation of it is known as reverse engineering, sometimes known as backward engineering.

This method can be used to develop fresh iterations of items or update stale ones. Engineers and designers can use it to deal with existing goods that don’t have CAD models or technical documentation.

Reverse engineering methods have advanced from manual measurements to 3D scanning, which offers a range of options.

3D Scanning in Reverse Engineering

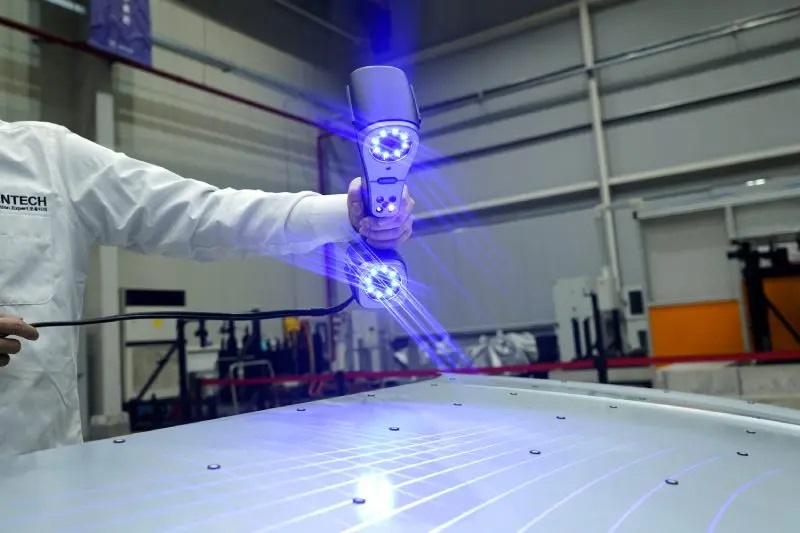

High-tech 3D scanning for reverse engineering is a method that uses lasers or structured lights to record the 3D data of items, from which you may learn the forms and dimensions of those objects.

Users can acquire point clouds—which represent the surfaces of things and can be translated into mesh models—from 3D scanning.

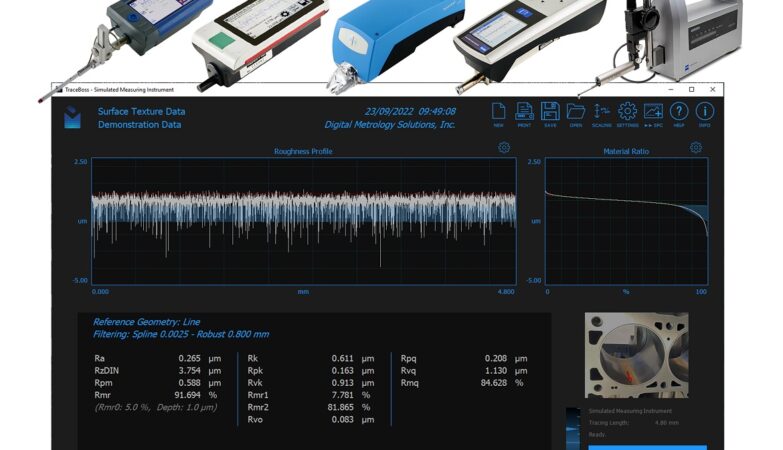

Categories of Measuring Methods

Depending on the size, complexity, required accuracy, and material qualities of the object to be scanned, various measurement kinds are available for reverse engineering applications. Typical categories include:

Contact Probes: Engineers utilize probes to determine an object’s coordinates and surface area. Contact scanners can harm soft or delicate objects and are accurate yet slow.

Non-contact 3D Laser Scanners: There are two primary types of non-contact 3D laser scanners for reverse engineering: 3D laser scanners and structured-light 3D scanners. Professional 3D laser scanners can gather the coordinates of points on surfaces and objects by projecting laser beams onto the objects.

Non-contact Portable 3D scanners that use structured-light technology display patterns onto objects and use cameras to capture surface deformations.

As a result, these 3D scanners may collect product geometrical data as well as colors and textures. No-contact 3D scanners are adaptable, precise, and quick at collecting 3D data.

They are able to perform full-field 3D scanning without endangering any of the objects. Reflective, dark, or clear surfaces may provide challenges for certain of these 3D scanners.

Photogrammetry: This method reconstructs an object’s geometry using a number of photos taken at various angles. Although photogrammetry is simple to use, it may not catch fine details and calls for high-quality photos.

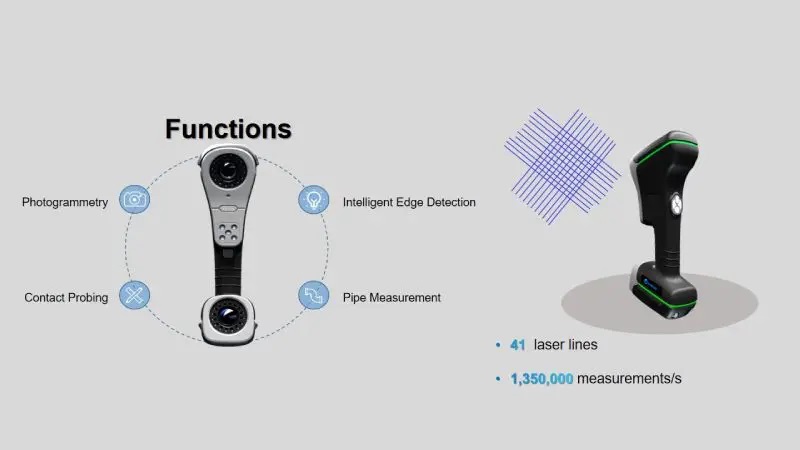

Scantech’s Industrial 3D Scanners for Reverse Engineering

The KSCAN-Magic series 3D laser scanner is the first that combines infrared and blue lasers into one single instrument.

It offers five standard working modes:

♦ Large-area scanning (global initiative infrared laser)

♦ Fast scanning (blue laser crosses)

♦ Fine scanning (blue parallel laser)

♦ Deep-hole scanning (single blue laser)

♦ Built-in photogrammetry system.

With two sets of high-definition industrial cameras, it can conduct 3D scanning meticulously. It is suitable for backward engineering in industries such as manufacturing, energy, automotive, and rail transportation.

Workflows of 3D Scanning to CAD Modelling

An object can be reverse-engineered using software tools that allow editing, altering, analyzing, or recreating its design after it has been scanned using a 3D scanner.

Using 3D scanning, some typical reverse engineering steps include:

3D scanning: To create point clouds, 3D scan the component using accurate, expert-grade 3D laser scanners.

Cleaning out noise, outliers, or undesirable points from the point cloud data is called point cloud processing.

Mesh Generation and Optimisation: Create a mesh model from the point cloud and fine-tune it to make the data easier to manage in CAD.

Surface extraction involves importing the mesh into CAD software to identify key surfaces. In this step, smooth surfaces are created and fitted to the mesh model’s recognized regions. Using the scan model as a guide, designers may rapidly and precisely construct sketch planes.

By defining features, characteristics, and other elements, a surface can be transformed into a solid model using solid modeling and redesign. For further design, the solid model can be applied and altered.

Benefits of Using 3D Scanners

Measure Complex Parts

Complex structures that are impossible or challenging to measure using traditional techniques can be captured with 3D scanning.

Handheld 3D scanners make it considerably simpler to measure tight spaces, difficult-to-reach places, or parts with fine details like gears and turbines because of their laser scanning and non-contact measurement capabilities.

As a result, engineers may rapidly build new products based on current parts and designers are able to produce realistic models that reflect real-world aspects.

Enhance Creativity and Innovation

Reverse engineering using 3D scanning can boost imagination and inventiveness. The use of a 3D scanner allows designers to experiment with various concepts and options based on already existing objects.

For instance, a 3D scanner can digitally alter the curves of an existing car model to increase aerodynamics.

As an alternative, a 3D scanner may capture images of several things and merge them to create a single new design. Designers may be able to produce distinctive goods that address particular demands as a result.

Save Time and Money

When compared to more conventional techniques, reverse engineering using 3D scanning can save time and money.

For instance, a 3D scanner can accurately collect millions of points on an object’s surface in a matter of seconds instead of manually measuring an object with calipers or coordinate measuring machines (CMMs), which can be time-consuming and difficult. This can shorten the design process and prevent rework and errors.

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.