The integrated solution to collect and manage digital gauge measurement data within the PolyWorks® Smart 3D Metrology Digital Ecosystem™

This content was originally written and published by the InnovMetric team on their website. Reproduced here from this link.

InnovMetric Software Inc., the global leader in smart 3D metrology software solutions, announced the release of a new entry-level PolyWorks|Inspector™ Gauging package to help manufacturing organizations collect and manage digital gauge measurements within their PolyWorks® digital ecosystem. In addition to being an out-of-the-box gauging solution that offers the standard functionalities commonly found in digital gauge manufacturers’ software, PolyWorks|Inspector Gauging features powerful CAD-based tools, 3D measurement guidance, nominal feature creation, and more to perform 3D inspections using digital gauge measurements.

“The need to integrate digital gauge measurements to PolyWorks naturally emerged as customers started to implement the PolyWorks|DataLoop™ data management solution,” said Marc Soucy, President of InnovMetric. He added, “Early PolyWorks|Inspector™ DataLoop adopters came to realize the efficiency gains that would be achieved by bringing all types of measurement data from all sources within our enterprise solution. We materialized their wish in the form of a new package specifically dedicated to industrial gauging applications. Once all your point cloud and CMM data are stored, collected, and managed in a centralized database, experts in different fields companywide can collaborate like never before using complete real-time 3D measurement information and SPC statistics, via a Web-based interface, to rapidly solve production quality issues.”

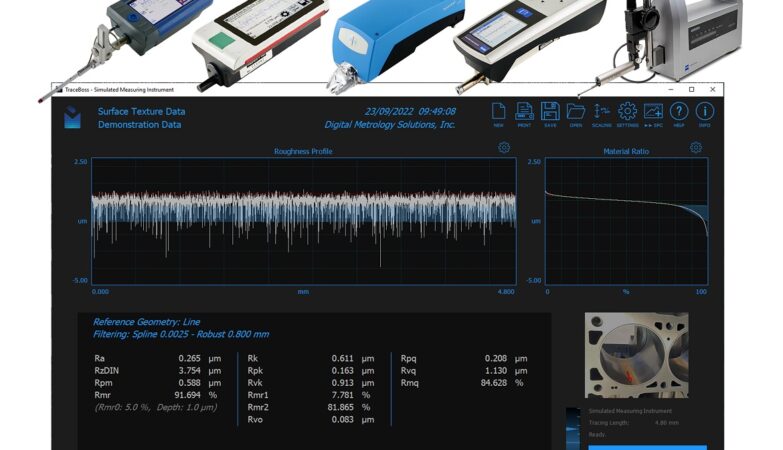

A Modern Toolbox for your Digital Gauging Needs

PolyWorks|Inspector™ Gauging includes powerful inspection tools based on CAD data that facilitate the preparation and execution of measurement sequences and the review of measurement results.

It allows users to:

- Import and display 3D CAD models in IGES or STEP format

- Create nominal 2D/3D features from a single click on a CAD model

- Use created features to specify the dimensions that will be gauged

- Enjoy full 3D measurement guidance while gauging a dimension

- Review and share measurement results in 3D using control views

It also offers the full set of functionalities commonly used in gauging software, including:

- Automated digital gauge data collection, through data collector plug-ins and Bluetooth-ready input dialog boxes

- Manual measurement data entry for analog gauges and visual checks

- Measurement sequence creation and execution

- Measurement guidance through photos and textual instructions

- Formatted PDF reports and smart Excel integration

- Multipiece measurement capabilities and Statistical Process Control (SPC)

PolyWorks|Inspector™ A Single-Vendor Enterprise Solution for All your 3D Measurement Processes

For existing PolyWorks customers, PolyWorks|Inspector™ Gauging represents a unique opportunity to unify their 3D measurement community, create synergies that reduce operating costs, and efficiently share best practices, data, and measurement results:

- The offline preparation team that creates inspection projects for portable metrology devices or CMMs can also create measurement templates for digital gauges

- As PolyWorks offers a universal 3D measurement workflow across all the measurement devices it supports, all PolyWorks users can readily operate digital gauges without a formal training

- Bringing digital gauge data within PolyWorks makes it possible to aggregate all 3D measurement data from all sources within PolyWorks|Inspector projects and share the measurement results in 3D enterprisewide

To know more, please check InnovMetric.