The German fixturing specialist Witte is now presenting vacuum chucks in aluminium with integrated microporous material that can be heated up to 200 degrees Celsius. With this top feature, the new chucks primarily meet complex requirements in the high-tech area.

The core of the microporous chuck is a new heating element solution and a sophisticated programmable control system. In addition, the free and independent mounting on plate segments using different temperatures and suction forces. This flexibility in connection with an extremely harmonious surface temperature pattern make the chucks especially suitable for use in high-tech applications. For example when printing RFID foils or when measuring under the influence of temperature, for example carrier layers for flexible mobile phone displays, etc.

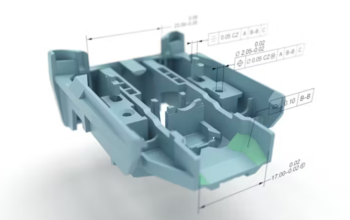

Microporous vacuum chucks from Witte ensure that the test part is clamped or held absolutely “level”. Thin materials are not pulled down by suction holes, suction grooves, etc., which avoids the risk of deformation. Especially in automation processes, the low weight and precision of the microporous chucks also score points.

The pressure distribution on the special structure of the chucks enables even load-bearing forces, even if the surface is only partially covered. This means that also workpieces of different sizes can be fixed on the same plate.

The new aluminium chucks with integrated microporous surface, which can be heated up to 200 degrees Celsius, are designed and manufactured by Witte according to individual customer specifications and their applications.