Scanning at depth – three-dimensional measurement of an ocean giant

Time is money – that’s the underlying motto in shipbuilding, especially when it comes to repairs and modernization work. After all, the dry dock phase is massively expensive. As a result, the production of 3D documentation for the ships needs to be fast and reliable. And the FARO® Laser Scanner offers optimum support.

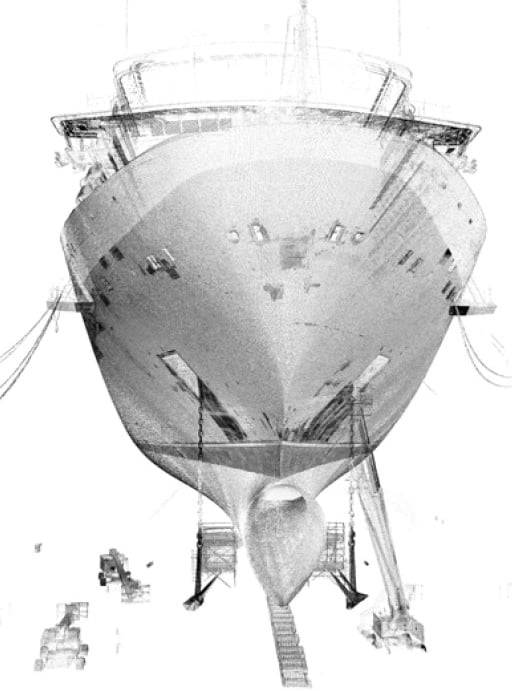

Sea cruises are seen as the epitome of an abundance of time and of relaxation. It’s a completely different ball game when it comes to running repairs on and overhauling an ocean liner in dry dock. Downtime for these giants is extremely expensive. Any work required must therefore be carried out quickly, and usually all at the same time. However, the dry dock does offer a unique opportunity to inspect the ship’s hull in detail and measure it accurately.

The QUEEN ELIZABETH 2 is one of the most arresting luxury liners in the world. She seamlessly blends modern ship design with classic elements from the golden age of ocean crossings. Her measurements are impressive too: 294 meters long, 32 meters wide and a magnificent 55 meters high. 12 passenger decks provide space for more than 2,000 passengers.

Following her launch in October 2010, in spring 2014 it was time for a general overhaul at the Blohm + Voss dry dock in Hamburg. The comprehensive cleaning and modernization programming had to be completed within the space of just two weeks. In addition, accurate measurements of the ship’s hull were scheduled to be taken during this time. Data obtained during this process was used to calculate the optimization of the hull. The goal was to develop new flow flaps and stabilizers and so to improve energy efficiency. In order to keep to the strict schedule and deliver the required accuracy, the contractor in question, SCAN3D Dienstleistungsgesellschaft, recorded the hull using a FARO Focus Laser Scanner.

What was so challenging about this scan was the time pressure and the limited room for maneuver in the dry dock

-Lars Sörensen,

Managing Partner – SCAN3D

Sörensen and his team had to integrate into the shipyard’s 24-hour working day at Dock Elbe 11 whilst causing as little disruption as possible. “When we take measurements in shipyards, we mainly have to work nights and at the weekend”, said Sörensen.

With the Focus, he was able to record the ship’s entire hull in two eight-hour scan processes comprising around 100 individual scans – both from underneath and at various height levels, given that the draft of this luxury liner alone measures 8 meters. “The Focus is ideally suited for working in confined spaces, such as those beneath the keel. It did not take much effort or time to set up, and we did not get in the way of other work taking place around us“. The laser scanner’s high measuring accuracy is incredibly important for the next steps in the process. With a standard deviation of 2.5mm on a ship 300 meters long and range noise in fractions of a millimeter, the laser scanner delivers a highly accurate map of the hull. This level of accuracy is vitally important given that it is not unusual to discover deviations of several decimeters from the planned hull design once the ship has been built.

The FARO Laser Scanner lets you work easily even in confined spaces and under massive time pressure. For us it serves as the ideal foundation for providing our clients with reliable and high-quality data, fast

-Lars Sörensen,

Managing Partner – SCAN3D

SCAN3D used LupoScan to process the captured data and subsequently produced a reliable surface model of the ship’s hull. Experts at an engineering firm in Finland were able to take this digital model and use it with CFD to analyze flow behavior around the hull. Flow flaps, stabilizers, and a new bulbous bow were then designed to help boost the energy efficiency of the ship’s propulsion.

“Our approach had one particular advantage: the data obtained was transformed directly into the ship’s coordinate system. This method produces significant time and cost benefits for future installations”, Lars Sörensen explained. “And the Focus enabled us to record basic geometric data quickly and reliably”.

SCAN3D DIENSTLEISTUNGSGESELLSCHAFT MBH

SCAN3D Dienstleistungsgesellschaft specializes in recording and documenting buildings and objects through 3D laser scanning. The company’s expertise ranges from buildings through mechanical engineering to measuring turbines and shipbuilding. Alongside asbuilt documentation, SCAN3D also delivers analyses, visualizations and models, and offers comprehensive consulting services on the use of scanners and on preparing and processing scan data thus obtained.

Four Good Reasons

- Speed: Recording even large objects and buildings are unbeatably fast with the FARO Focus3D.

- Accuracy: With a standard deviation of just 2.5 millimeters on a ship 300 meters long, the scanner delivers optimum accuracy, reliability, and speed.

- Compatibility: Scan data can easily be integrated into other CAD programs – providing optimum support for further processing of the data.

- Flexibility: This small, handheld device can be set up and dismantled in no time in various locations. You can work fast and flexible from different perspectives.