The new target frame from AESUB sets objects into position for optical measurement in just a few steps. A modular set allows to assemble target frames with a diameter of 200mm or 300mm. The frame is additively manufactured with plug and screw connections directly integrated to it. It can be, therefore, assembled without additional tools. As the frame is printed in black, no chemical finishing by coloring or anodizing is needed. All elements are compactly packed into one case, making the entire set ideal for mobile use.

Scan from all angles

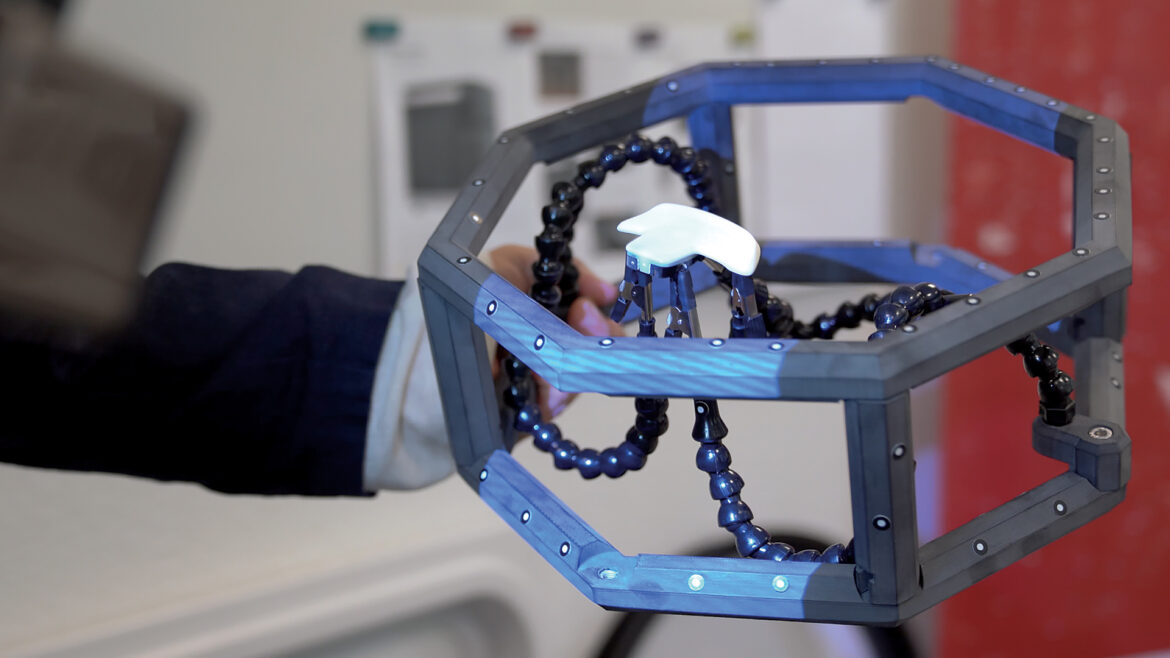

Flexible arms with clamps hold the object within the black frame so that it can be scanned from all angles. Reference points required for scanning can be placed directly on the frame instead of on the object. This saves a lot of time, especially during a repetitive measurement of identical objects such as for small batches or pre-series. The frame also simplifies the measuring process of single parts that require front and back scans. Without a target frame, such parts would have to be covered with many reference points so that overlapping points are visible from both sides. The modular frame can be adjusted to the size (height and width or diameter) of the measured object. This ensures that the optimum distance between the measuring points and the measuring object is always maintained.

Enjoy a new scanning experience

The frame is made of aerospace materials and weighs only half of the conventionally manufactured aluminum frames. Due to its light weight, users enjoy a fully new, fully flexible scanning experience when holding the frame in one hand and the scanner in the other. Individual frame structures can be also designed and manufactured on request.

Video:

Photo 1:

Case with additively manufactured components. Ideal for mobile use.

Photo 2:

The target frame with a diameter of 200 millimeters weighs only 500 grams, suitable for measurements with a hand-held scanner.

Photo 3:

Hold the frame with the one hand while scanning with the other

Photo credit: AESUB