3D scanning technology has been widely applied in many industrial fields, with the automobile transportation industry a typical example. There is fierce competition between carmakers. Throughout the whole cycle of car manufacturing, 3D scanning can be applied:

- At the design and development stage, it can collect 3D data of the outline of a product and its parts to assist the engineers in improving the outline, modifying the design, verifying structural rationality and doing virtual assembly and prototype adjustment, etc.

- At the manufacturing stage, we can use 3D scanning to inspect the quality of the whole car and its parts to ensure product qualification.

- At the after-sales and repair stage, it can analyze and detect parts with deformation to help to troubleshoot.

Case Analyze

Our client, a hardware accelerator company, prepared a Tesla Model 3 for data collection of the whole car and parts. They hope to do digital modeling, with the help of ScanTech 3D scanning technology, of the whole car, and all dismantled parts of it and realize the 1:1 digital reestablishment with 3D printing technology.

For large-sized workpieces like an automobile, the scanning area and speed are important factors when selecting a 3D scanner. Tesla Model 3 is 4.7m long, 1.85m wide, and weighs 1,614kg. A narrow scanning area will lead to multiple stitching to get complete 3D data, which will easily cause accumulative errors. Meanwhile, the scanning area and speed will have a direct influence on work efficiency.

Besides, the automobile is such a highly sophisticated industrial product that it has a high demand for the accuracy of a 3D scanner. The higher accuracy means the more proximal of the digital model to the real object, which is better for further analysis and study.

The structure of the automobile is complex. Whether the 3D scanner can work normally on complicated positions such as curved surface, deep hole, and dead angle or a black surface or not will affect the result of scanning.

ScanTech 3D Solution

KSCAN-Magic 3D scanner opens up the first introduction of infrared laser + blue laser technology, with built-in photogrammetric system, scanning area up to 1440 mm × 860 mm, scanning speed 1,350,000 measurements/s, scanning accuracy 0.020 mm, resolution 0.010 mm, and volume accuracy 0.030 mm/m. The KSCAN-Magic 3D scanner is suitable for high accuracy large area scanning, the best choice for Tesla whole car scanning.

For details and parts of the car, KSCAN-Magic can realize superfine scanning with 7 parallel blue laser lines and deep hole scanning with a single blue laser line, to acquire precise 3D data of deep holes and dead singles. Even at the highlighted surface and black surface, KSCAN-Magic can work normally.

Therefore, KSCAN-Magic composite 3D laser scanner is a real multi-purpose device. It can complete the 3D scanning of the whole car and all dismantled parts without an assist from other machines.

Photogrammetric system

The bulk of the car is large, for the ordinary 3D scanner, the scanning requires a huge amount of work. However, for KSCAN-Magic, the work process can be simplified, and the work efficiency improved because the built-in photogrammetry system can obtain more accurate 3D data of positioning markers and get 3D data with higher accuracy. Thus, we can correct the point cloud information of the large curved surfaces and greatly increase the overall stitching accuracy of the point cloud stitching.

3D laser scanning

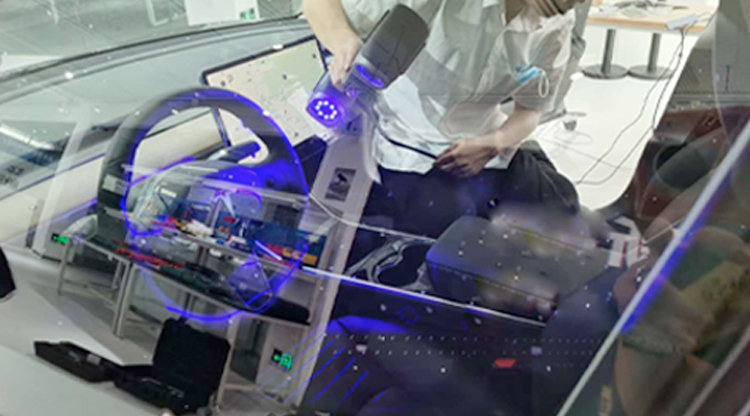

Scanning Tesla includes the scanning of the whole car and parts like car interiors, seats, and steering wheel. There are five work modes for KSCAN-Magic: global initiative infrared laser large area scanning, blue laser crosses fast scanning, blue parallel laser fine scanning, single blue laser deep hole scanning, built-in photogrammetry system. Different work modes can be flexibly shifted according to different parts.

Meanwhile, KSCAN-Magic is a handheld 3D scanner. Its portability and flexibility make it convenient to be applied in a narrow space like car interiors. It can also be applied to the shiny and black surface without the need to spray powders on it, reducing the harm to the car body.

Obtaining STL data

Import the scan data into professional 3D software ScanViewer to do post-processing and get an accurate 3D model. Then with the help of 3D printing, the 1:1 Tesla model will come into being.

3D scanning solution can accelerate product development, raise inspection efficiency and improve the product quality for the whole car and automotive parts manufacturers, and help them occupy dominant positions in the fierce competition. In addition, the 3D data can also be applied in the teaching of automobile repair. In this case, ScanTech helped the client import these data resource into its digital automobile repair training base for the usage of virtual simulation teaching, meeting the needs of teachers and students in the tide of 5G+VR/AR.

For more information, please check ScanTech.