Credits: Polyga

1.0 Introduction

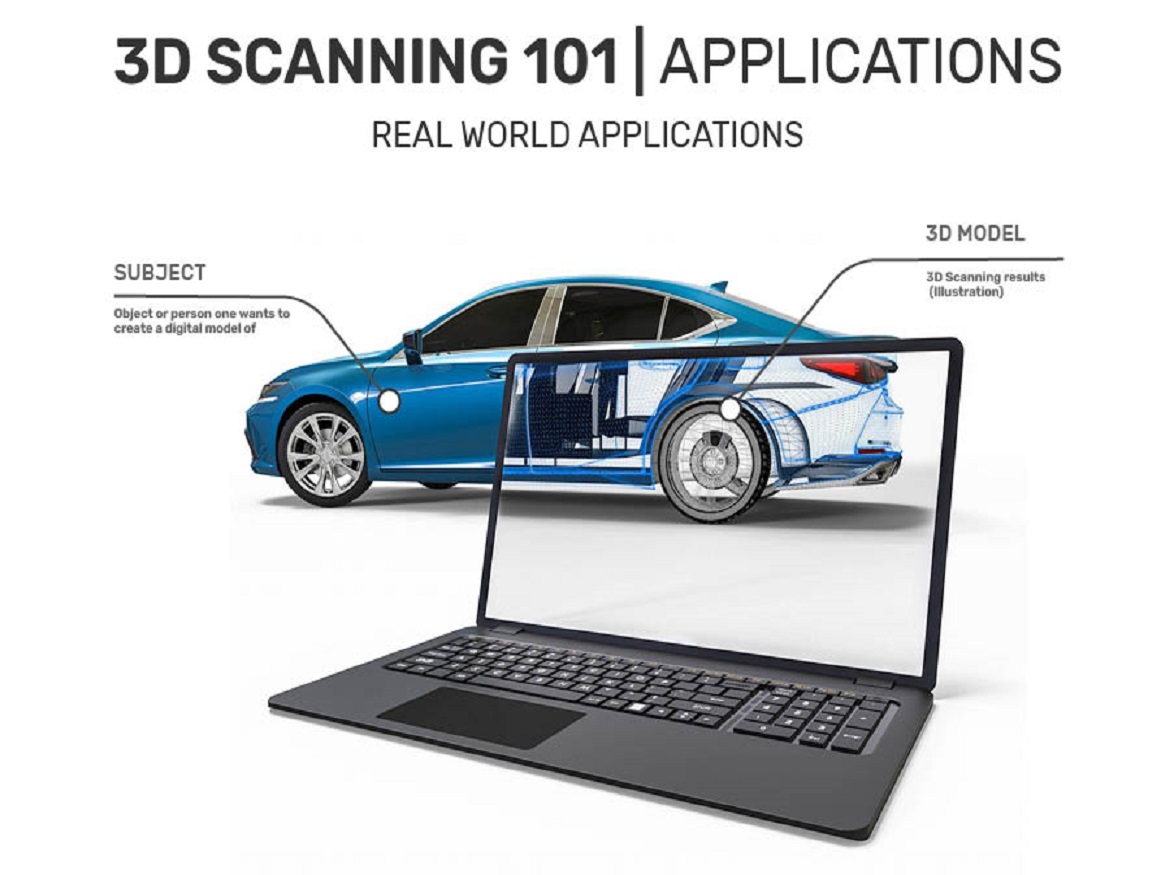

In Part 1 of 3D Scanning 101, we learned the basics of how structured light technology uses projected light patterns and camera to accurately measure three-dimensional shapes. Now let’s delve into the practical, real-world applications of structured light 3D scanning. Part 2 explores the multifaceted commercial applications of structured light 3D scanning from industries all over the world.

The Basics

What are 3D Scanning Applications for? A 3D scanner is useful in applications where:

- You rely on having accurate 3D measurements

- You need to capture large amount of surface measurements quickly and efficiently

- Need to reconstruct a physical object in 3D to be visualize digitally

- You require a subject safe non-destructive measurement or capture

Automotive & Transportation

Design & Prototyping: Automotive designers rely on structured light 3D scanning for creating models of cars and components. It also provides designers with immediate cost-effective testing in virtual wind tunnels compared to time consuming real-world testing methods like physical tracks and wind tunnels. Structured light 3D scanning technology enables rapid prototyping, faster iterations, and design improvements while lowering costs.

Quality Control & Inspection: In manufacturing, these scanners ensure parts meet specifications. They are used for inspecting, verifying dimensions, and detecting manufacturing defects, thereby reducing waste and improving efficiency.

Reverse Engineering: Scanners facilitate the reproduction of parts such as in vintage cars where original blueprints might not be available, allowing for precise replication and measurement.

Aerospace & Defense

Component Analysis & Maintenance: Used for inspecting and analyzing aircraft components, these scanners provide crucial data for maintenance and safety checks, especially in areas difficult to measure manually.

Custom Tooling & Fixtures: Structured light scanning aids in designing custom tools, parts and fixtures tailored to specific aerospace components, enhancing the efficiency of manufacturing and assembly.

Reverse Engineering of Legacy Parts: It enables the replication of parts for older discontinued aircraft models or parts, ensuring continued operation and maintenance while reducing costs.

Healthcare & Dental

Prosthetics & Orthopedics: Custom prosthetics and orthotics are created using 3D scans of the subject’s body, ensuring a perfect fit and increased comfort while reducing any risk or pain to the subject as a non-contact measurement method.

Dental Scanning: Dentists use structured light scanners for precise dental impressions, leading to better fitting crowns, bridges, and orthodontic devices while reducing the pain and discomfort associated with casts and older replication methods.

Surgical Planning & Implants: Surgeons utilize 3D models for pre-surgical planning, especially for complex procedures reducing risk for the subject. Custom implants and medical devices can also be created based on these scans.

Historical Preservation & Archaeology

Artifact Digitization: As a non-destructive contactless method of digitization; structured light scanning is excellent in digitizing artifacts for preservation, measurement, and study where conserving the subject is important.

Restoration Work: Structured light scanning assists in the restoration of historical sites and artifacts by providing accurate 3D models that can be analyzed and manipulated without any risk to the subject.

Entertainment & Media

Visual Effects (VFX): In film and gaming, scanners capture detailed 3D models of objects and actors for realistic VFX and animation faster and more precisely then other VFX methods.

Video Game Development: In the realm of video game development, structured light 3D scanning offers developers the ability to bring characters and worlds to life with unprecedented detail and authenticity.

Virtual Reality (VR) & Augmented Reality (AR): Scanning real-world objects and environments creates immersive VR and AR experiences.

Tool & Die Making: Scanners aid in the design and manufacturing of tools, dies, and molds with high precision ensuring the highest manufacturing standards.

Quality Assurance: In production lines, structured light scanners are used for rapid quality checks, ensuring products meet design specifications.

Assembly Line Integration: They are used to ensure components fit perfectly, reducing assembly time and errors.

Retail & Fashion

Custom Apparel Design: Fashion and retail have embraced structured light scanning for custom tailoring, ensuring garments fit perfectly to individual body shapes without requiring the subject to physically be there.

Footwear Industry: In footwear design and orthopedics, 3D scans ensure ergonomically designed, comfortable shoes tailored to individual feet.

Conclusion

The adoption of structured light 3D scanning continues to mature and grow across many different industries, underlining its role as a cornerstone of modern commercial and industrial technology. Its applications span diverse sectors, driving innovation, enhancing quality, and optimizing processes. The future looks bright with the promise of even more ingenious applications, solidifying structured light 3D scanning as a pivotal tool in the commercial and industrial segment.