This post will describe how Top3dShop scanned an electric vehicle for EVTech utilizing a RangeVision PRO 3D scanner. The project’s goal was to update the car’s details and redesign its outside. According to the scan’s findings, the car’s body, hood, and fenders needed to be upgraded, and they had to be made utilizing rotational molding and automatic vacuum forming.

In a short period of time, it was required to improve the car’s body and interior, streamline the arrangement of various parts and assemblies, and update the design to reflect the modifications.

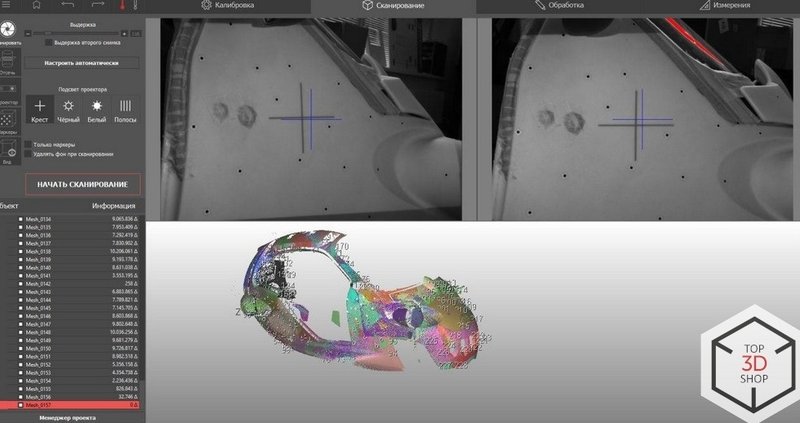

Before scanning, the reflective and dazzling surfaces were covered. The markers were used to form a grid that aids in computing the coordinates of the points by the scanner. For easy calibration, if the scanner has been moved, the tools and the calibration board were also installed.

There will be no issues during frame alignment because the markers are positioned in a random order, and the scanner will be able to precisely recognize the geometry of the scanned surface without any complications.

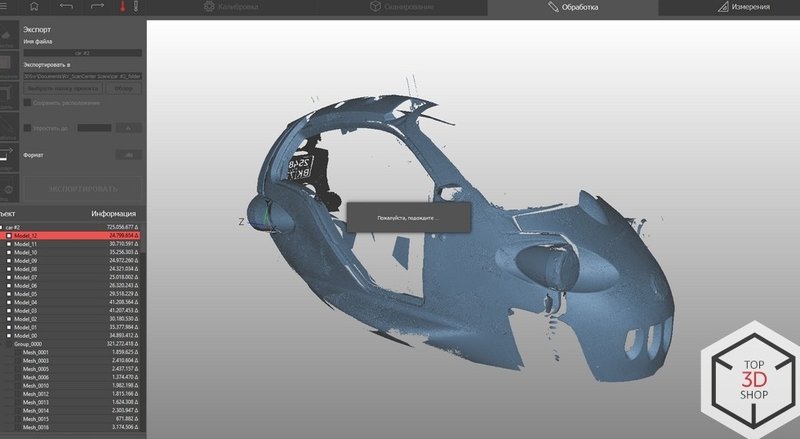

The automatic simplifying feature of the Rangevision Scancenter program was used to consolidate and save projects with more than 1,500 points.

After the setup and work instructions were followed, Top3DShop was pleased with the result: “The Rangevision Pro has proven to be a high-quality professional scanner. We can suggest using it for engineering reasons across a variety of industries, including R&D for automobiles, motorbikes, small boats, and motorboat body parts, as well as for modding and maintenance.

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.