Ho Chi Minh City University of Technology (HCMUT) boasts a rich history spanning 70 years. As a renowned local institution, HCMUT plays a significant role in technical education and research within the southern region of Vietnam.

In this case, we will show you how this esteemed university optimizes its education and research with Scantech’s 3D solution.

HCMUT offers a wide range of courses, including automotive driving and maintenance as well as metal smelting. These programs equip students with practical skills and theoretical knowledge, preparing them for careers in various industries.

Notably, the university collaborates closely with relevant automobile repair shops and car manufacturers to bridge the gap between academia and real-world applications.

By using Scantech’s TrackScan-Sharp 49, the teachers and students in HCMUT reverse-engineered a car frame from scan to CAD.

Reverse engineering

Reverse engineering is the process of investigating an existing product to uncover the underlying concepts involved in its fabrication. The ultimate goal is to either create a similar product or enhance an existing one. It serves as a powerful tool for innovation.

The exact process for reverse engineering varies based on the type of object being studied, which typically involves the following steps: data capturing, data processing, CAD model recreation, CAD editing and optimization and final verification.

Challenges of Conventional Method for Reverse Engineering

Traditionally, the reverse engineering workflow involved measuring parts manually and creating basic sketches using 3D modeller software. These sketches were then transferred to 3D CAD design software to complete the reverse engineering process.

Cumbersome Process: Unfortunately, when measuring parts with traditional methods like callipers tends to be time-consuming and prone to errors.

Besides that, engineers need to be familiar with the software and have a deep understanding of complex features to ensure precise modelling. The precision of 3D modelling is highly related to the subjective judgement of modellers.

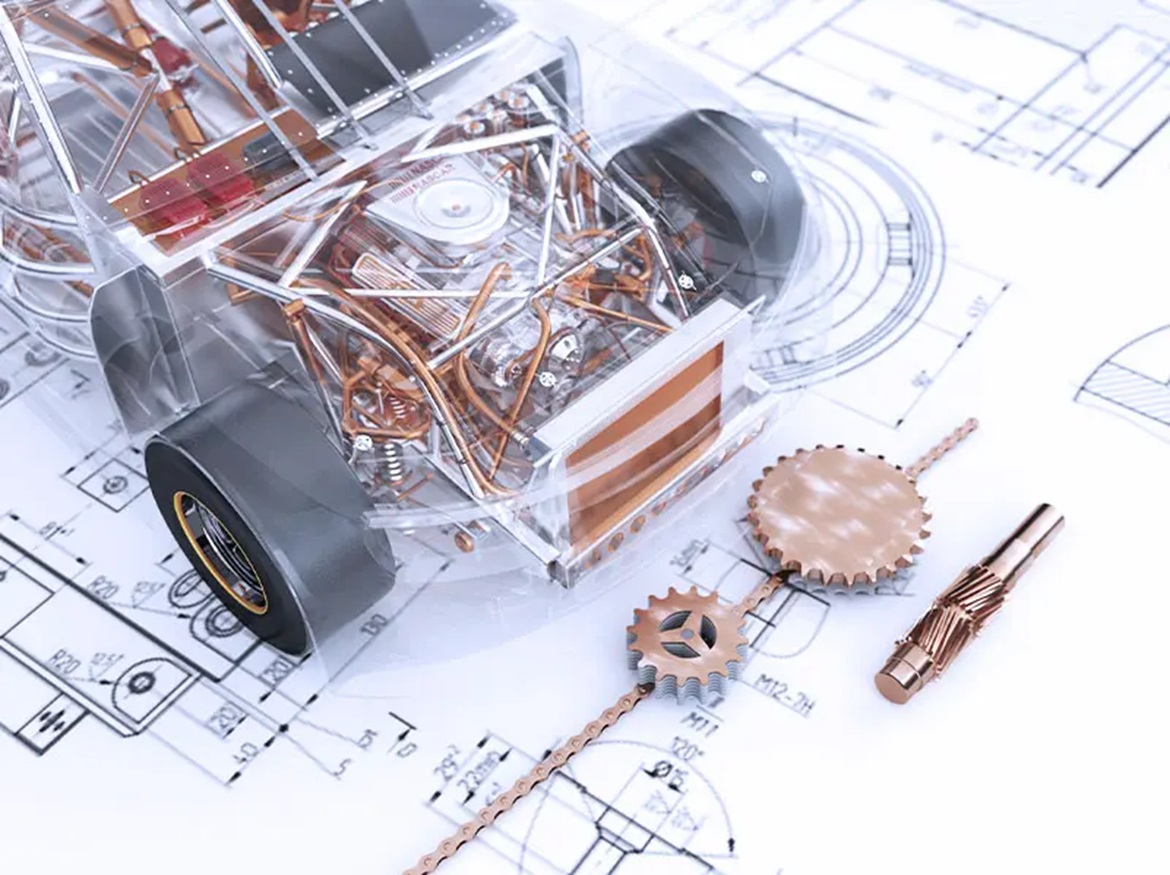

The Project: Reverse Engineering a Vehicle Frame

HCMUT aimed to scan the entire vehicle frame for reverse engineering purposes. The goal was to capture detailed 3D data of the frame, enabling further analysis and innovation.

Given the substantial dimensions and intricacy of its design, using conventional techniques for reverse engineering becomes challenging. However, this is where 3D scanning technology proves invaluable.

Enabling Direct Reverse Engineering into CAD Design Software

HCMUT has used an innovative Scan-to-CAD process for reverse engineering, which is much more efficient than traditional methods.

Using the optical 3D measurement system TrackScan-Sharp 49, HCMUT significantly enhances its capability to reverse engineer projects in its education and research.

This streamlined approach enables the direct capture of 3D measurements from physical components, serving as a precise reference for creating the corresponding CAD model.

Challenges in Scanning Car Frame

The frame acts as the skeleton of the vehicle, offering a robust structure that bears the vehicle’s weight and accommodates critical components.

Complex Features: The vehicle frame features complex structure, and intricate details including curvatures, holes and edges, which add complexity to the scanning process.

Large Dimensions: With approximate dimensions of 2.5 meters in length, 1.5 meters in width, and 0.8 meters in height, the frame presents a significant challenge for 3D scanning due to its large size.

Eroded and Complex Surfaces: Having been in use for an extended period, the frame shows signs of rust, which further complicates the task of capturing precise data during the scanning process.

The Solution: Trackscan-Sharp 49

To address these challenges, HCMUT used the optical 3D measurement system TrackScan-Sharp 49. It consists of a 3D scanner and i-Tracker, which is suitable for measuring large-scale parts with a volumetric accuracy of up to 0.049 mm (10.4 m3) and a measurement volume of up to 49 m3.

Efficient Scanning Process

The TrackScan-Sharp 49 significantly reduced scanning time. By using advanced algorithms and optimized hardware, the scanning process had been streamlined to an impressive 1.5 hours.

This efficiency is crucial for time-sensitive projects, allowing researchers, engineers, and artists to focus on analyzing the data rather than waiting for lengthy scans.

Accurate Measurement Results

TrackScan-Sharp 49 delivered unparalleled results. Its high-resolution sensors captured intricate details with remarkable fidelity. When used in educational settings in this case, the device ensured that the acquired data was reliable and precise.

The scans produced by the TrackScan-Sharp 49 served as valuable resources for creating 3D models, advancing understanding of complex structures, and achieving innovations.

Benefits of 3D Scanning for Reverse Engineering

Enhancing Efficiency with 3D Data: When compared to traditional time-consuming manual measurement and CAD modelling processes, using 3D data significantly reduces time investment. The process begins by capturing a point cloud. From this point cloud, a highly detailed 3D model can be generated.

Precision Enhancement: This streamlined approach not only saves time but also enhances precision and accuracy. SCANTECH 3D scanning excels at capturing the precise shapes and features of real-world objects. This accuracy contributes to the creation of more reliable digital models.

Fast Sketching: Using 3D scanning, the operator captured the precise 3D data of a real-world car frame. By importing 3D data into reverse engineering software, the client effortlessly extracted sections, and fit features to create a precise sketch, which is essential for subsequent modelling and design processes.

Rapid Designing: With the help of functions such as extruding, revolving and solid primitive in the CAD design software, the user created a detailed 3D model of the car frame. Based on the precise 3D model, students and teachers are confident in determining the design intent of the car frame.

Significance of the Project

In summary, HCMUT continues to drive innovation, bridging academia and industry through cutting-edge technologies like the TrackScan-Sharp 49. This project marks a significant step forward in their journey of educational excellence.