Museums amass priceless historical artefacts. It serves as a portal to the past. Many sculptures, pieces of sculpture, and other historical artefacts serve to memorialise the past. With the use of 3D scanning technologies, historical preservation and reverse engineering procedures are made possible. Find out more about a scan of a historic statue here.

The goal: a precise scan for the replica of the statue Nike

The War Museum in Greece is one of Southeastern Europe’s and the nation’s largest military history museums. It gathers artefacts from all eras of Greek warfare. A memorial will be erected at the war museum in recognition of the approximately 1600 Greeks who gave their services—and sometimes even their lives—to aid in the liberation of Greece.

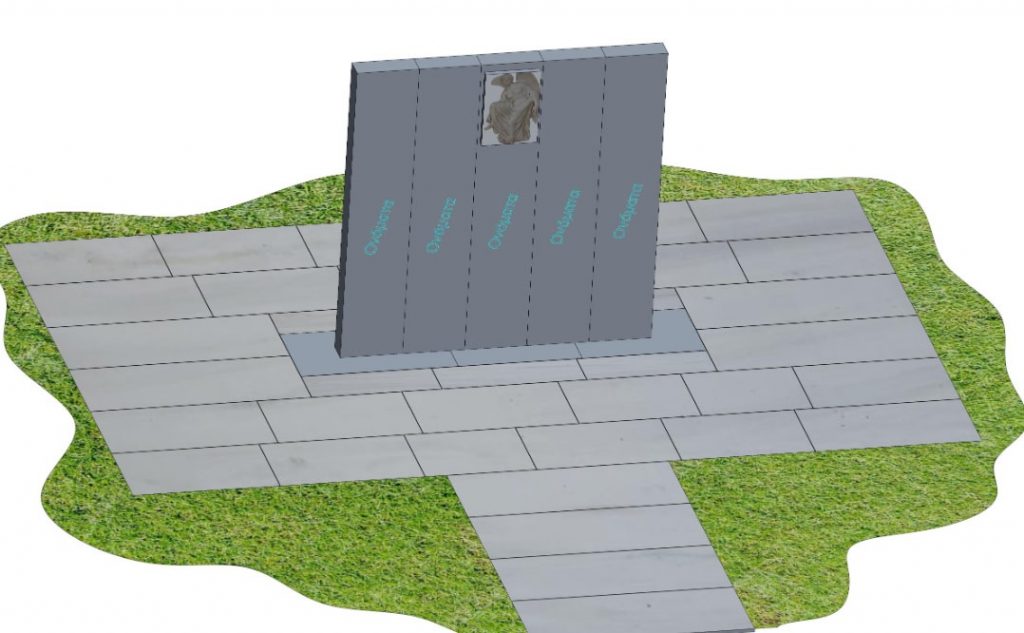

The well-known Nike (Goddess of Victory) statue needs to be reproduced for the Monument of Philhellenes in its corrected form. The replica will be inscribed in the monument’s centre (Fig. 1).

In this application example, a 3D scan of the original statue is made specifically for this purpose. A CNC cutting machine will then be utilised to create the marble copy utilising the information gathered.

The challenge of scanning

The application’s difficulty is in producing a perfect scan and later clone of the monument.

The application environment makes the work initially difficult. Collecting scan data is challenging because of the small area and the statue’s installation on the wall.

The statue is a rather large object to scan at 1,2 m by 0,60 m in size. Also, the original is distinguished by a wealth of details that should be preserved as much as feasible. Every piece of information must be accurate and dependably collected in order to produce a statue replica that is as precise as possible.

When scanning the Victory of Goddess, both conditions must be taken into account.

Since the statue is made out of a marble block using a CNC marble cutting machine, the scan data must be as accurate as possible.

The solution for exact 3D scans

The computerised statue served as the final element of the replication jigsaw.

GOM Scan 1 was used to scan as quickly and precisely as feasible. The stereo camera method and blue light technology used by the 3D scanner allow for the creation of precise and accurate meshes.

The GOM Scan 1’s lightweight design and small size proved to be particularly advantageous for tight settings at a museum. The measurement volume also made it possible to digitise the medium-sized portion and capture fine and minute information.

Curious about what else the GOM Scan 1 has to offer?

This work was done by Lino Integrated Printing Solutions. Lino has been a trusted member of our network and is skilled in the application of 3D scan technologies. They decided on the GOM Scan 1 based on their extensive experience.

According to Michalis Bratsolias of Lino Integrated Printing Solutions, scanning the entire statue nearly entirely without reference points was accomplished by utilising the fringe projection method.

The GOM Inspect software is used to run the scanner. The statue was substantially digitalized using this method. It led the user through the scanning procedure step-by-step. As a result, the software’s ongoing assurance made accurate measuring possible.

Click on the following link Metrologically Speaking to read more such blogs on Metrology.