Are you looking for professional handheld 3D scanners to accelerate your project’s workflow? Are you confused by various specifications and descriptions?

To ensure that you have all the necessary information to make the right decision, we have created this blog to help you choose handheld 3D scanners.

This article will explain the difference between 3D laser and structured-light scanners and core factors, such as accuracy, resolution, and scanning rate when choosing 3D scanners. We would like to shed some light on how to choose a 3D scanner.

Cutting-edge 3D scanning technology has been widely adopted in various industries. Engineers, product designers, and researchers use 3D scanning for 3D printing, aerospace, and entertainment.

These 3D scanners can obtain 3D scan data efficiently, which allows them to construct 3D models or run inspections to determine deviations. Handheld 3D scanners are gaining more and more attention because of their portability, ease of operation, and quick results.

These 3D scanners can be mainly divided into 3D laser and structured-light scanners. Let’s first look at the principles behind 3D handheld scanners.

Handheld 3D Laser Scanner

3D laser scanners cast lasers onto objects, and their sensor analyses the lasers reflected to determine positions in space. Being not sensitive to interference, lasers can adapt to different measurement conditions.

However, laser beams can be affected by speckle noise and Gaussian noise; the resulting effects vary depending on the type of laser source: blue laser and red laser.

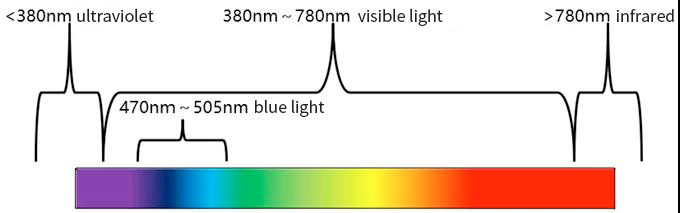

Using a red laser scanner and a blue laser scanner, we scanned a calibration board with points at 1-mm intervals. From the picture shown below, we can see that a red laser shows more significant speckle noises than a blue laser.

It means that the anti-interference ability of the blue laser is more robust than that of the red laser.

Now, let’s compare blue laser and infrared laser. The wavelength of the blue laser is shorter than that of the infrared laser. Because of its characteristics, a blue laser is better for scanning intricate details.

When it comes to scanning large-scale objects, an infrared laser with a longer wavelength shows a better scan result.

Scantech, one of the pioneers in China to develop handheld 3D scanners, brings infrared laser and blue laser into one single instrument. Scantech 3D handheld scanners can scan objects from coins to planes with vivid and fine details.

Handheld 3D Structured-light Scanner

A Handheld 3D structured-light scanner projects white light patterns onto an object and the distortion of the pattern can be used to reconstruct its geometric shape.

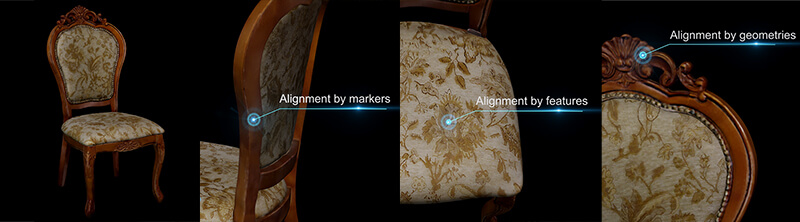

The scanner can position itself through natural features, textures, and colours. It takes one shot per frame and stitches scans from different positions to form a 3D point cloud.

There are two imaging algorithms of structured-light scanners: grating and speckle. When scanning reflective or transparent surfaces with grating technology, we need to apply a light or fine layer of powder onto objects.

3D scanners with speckle technology are featured by flexibility, easy operation, and fast scanning.

These scanners are widely used in non-industrial areas as they perform well when scanning medium-to-large objects like ancient artefacts and humans. The data they captured are of high resolution and have good details.

Next, we move on to the factors we need to consider when choosing a 3D handheld scanner. Find a scanner that fits your size, accuracy, and resolution requirement.

Factors for Choosing Handheld 3D Scanners

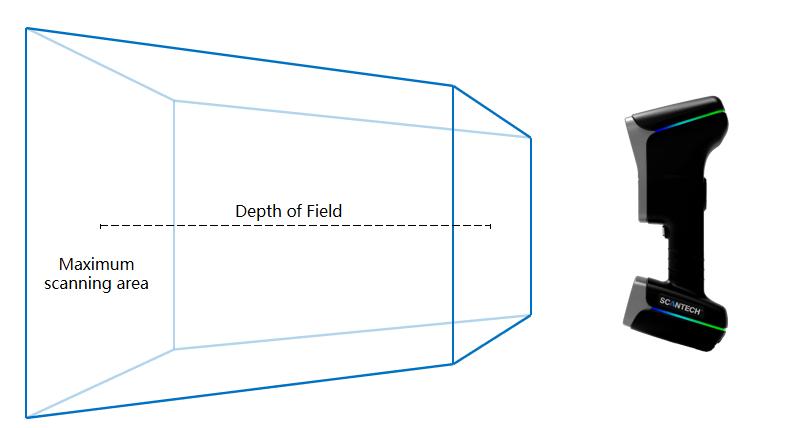

- Sizes of Objects& Scanning Area

How to choose a 3D scanner? You need to first think about the size of the object you want to scan. If you’re going to scan a small coin, a short-range 3D scanner that can capture intricate details in high resolution would be good.

If you plan to scan a large size object or part like a wind turbine, you need a long-range scanner with a larger field of view (scanning area). Let’s take Scantech’KSCAN-Magic as an example.

With its scanning area as large as 1440 mm * 860 mm, it can scan parts as long as 4 meters. It is especially suitable for 3D scanning for 3D printing and manufacturing.

- Accuracy

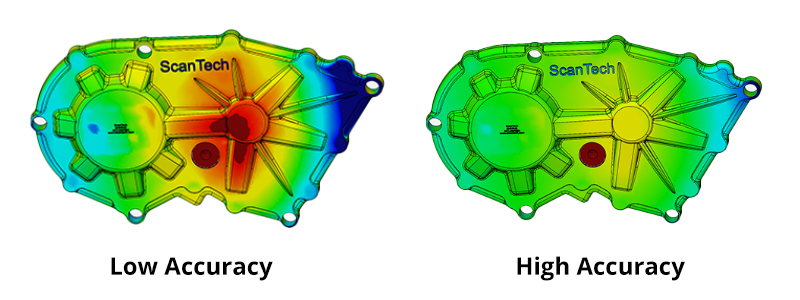

The accuracy of the scanning means the permissible deviation of each point captured. Generally, the accuracy of 3D scanners is within a range of 0.01 mm to 0.1 mm.

It would be acceptable for most tasks to use a 3D scanner with an accuracy of 0.06-0.07 mm. If you plan to scan a complex industrial part such as an airplane engine, choose a 3D scanner with high accuracy.

- Resolution

Resolution describes the minimum distance between captured points at a given scan distance. The higher the resolution, the denser the cloud of scan points.

When the details of a 3D model are essential to you, you would require a high resolution. If not, low-resolution requirements are suitable for you.

- Scanning Rate

When we talk about the scanning rate, we refer to how fast a 3D scanner can capture data off any given object. The rate varies depending on the number of laser lines, the size of the scanning area, and the algorithm of the equipment.

A top-of-the-range handheld scanner can measure up to 2 million times per second.

Know Who You Are Buying From

With a wide range of 3D scanners that come in all sizes, prices, and capabilities, choosing 3D scanners can be tricky. The top principle is choosing what’s right for you without causing too many expenses.

It is important to know who you are buying from. Make sure that you buy from a reputable company that provides advanced 3D scanning technology.

You can visit its official website to check the products, certificates, and customers. You can connect with the company to know what you are concerned about.

It’s good to read reviews online and check their social media accounts. In this way, you can know what the manufacturer is and what users say about them.

What kind of support does the company provide? Are there professional application engineers that can aid in calibrating and operating the 3D scanners?

Are there any professional after-sales teams that can provide support for maintenance or answer your questions? To know the details of what kind of support they can provide.

It is also a clever way to visit trade fairs to have a hands-on trial of the products. Talk to professionals to know the latest technology.

What We Offer

Scantech supplies professional handheld 3D scanners in all phases of the product manufacturing and production process to drive your business to great success.

These innovative professional 3D scanners increase your productivity and optimize your product life cycle management without the need to compromise between accuracy and efficiency.

KSCAN composite 3D scanner lineup is a series of professional, highly integrated, and handheld 3D scanners. It features an innovative “infrared laser + blue laser” scanning model, built-in photogrammetry, and is compatible with portable CMM and an automated 3D system.

It delivers highly repeatable scanning results with great details in high efficiency. It is suitable for both large-scale and tiny objects when it comes to measurement,. If you would like to know more, click the video below.

SIMSCAN, a compact handheld 3D scanner for industrial uses, is the only hand-sized portable 3D scanner on the market so far.

Whether in narrow spaces or under massive objects, SIMSCAN performs high-quality 3D scanning without any restriction of the working environment. Metrology-grade measurement system helps capture every detail and construct the 3D model in a very short time.