The significance of 3D scanning in various industries cannot be overstated, especially when the focus shifts towards reverse engineering. These tools continue to be increasingly integral to industry operations, so it’s paramount for engineers to thoroughly understand the nuances of selecting the right scanner for their needs. This guide delves deeper into six essential factors engineers should consider to make informed decisions without blowing budgets.

1. Purpose and Application: Understanding the Specific Needs

Before diving into the technical details, let’s first ask: “What do we intend to use this for?” Each sector, be it aerospace, manufacturing, architecture, or medicine, brings along its unique challenges and requirements. Understanding these nuances can make the difference between a project’s success or failure.

For instance, if you’re in the manufacturing sector, a scanner designed for aerospace might be overkill or may not even align with your specific needs. Alternatively, medical applications might necessitate a high degree of precision, whereas architectural endeavors may prioritize scale.

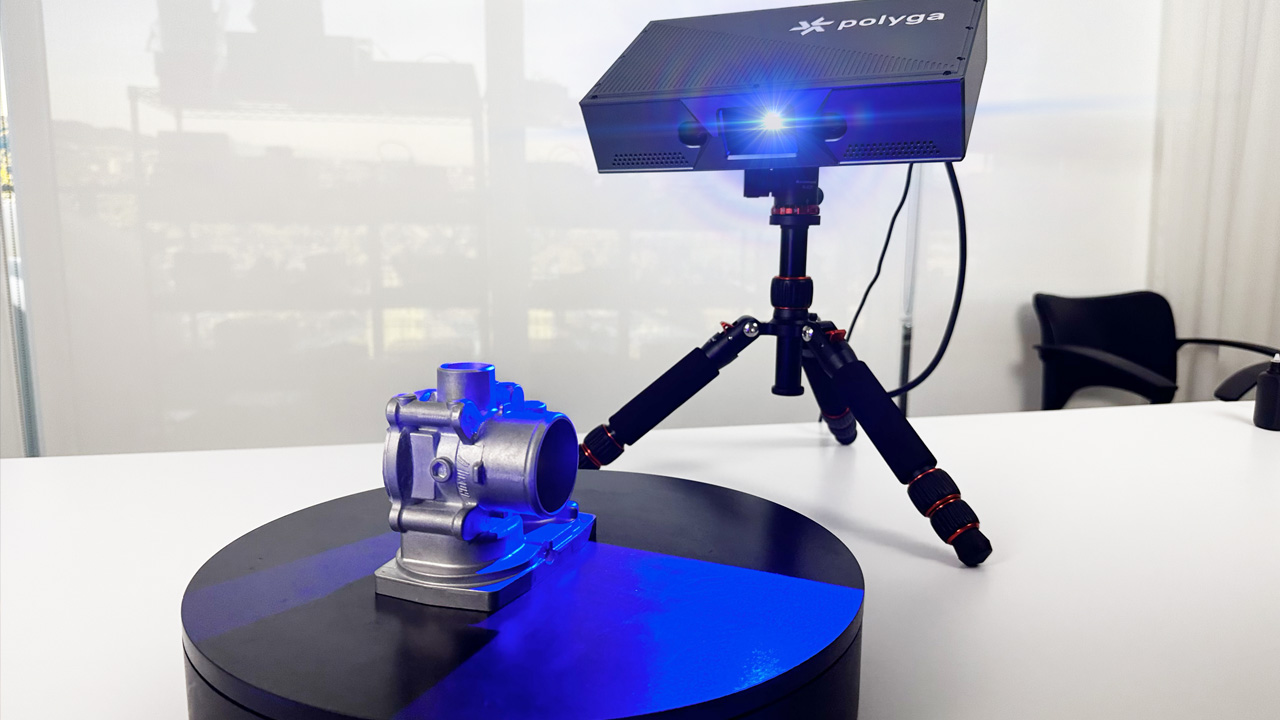

Highlighting the versatility and diversity in the market, products like the Polyga’s S1 Compact Pro Series have been developed to provide outstanding results at an affordable price. This desktop scanner is a testament to how manufacturers are designing products that seamlessly blend aesthetic appeal, top-of-the-line functionality, and affordability.

2. Durability: An Investment Worth Protecting

After ascertaining the purpose, consider the scanner’s longevity. For many companies, purchasing a 3D scanner is a significant capital investment, making its durability a prime concern.

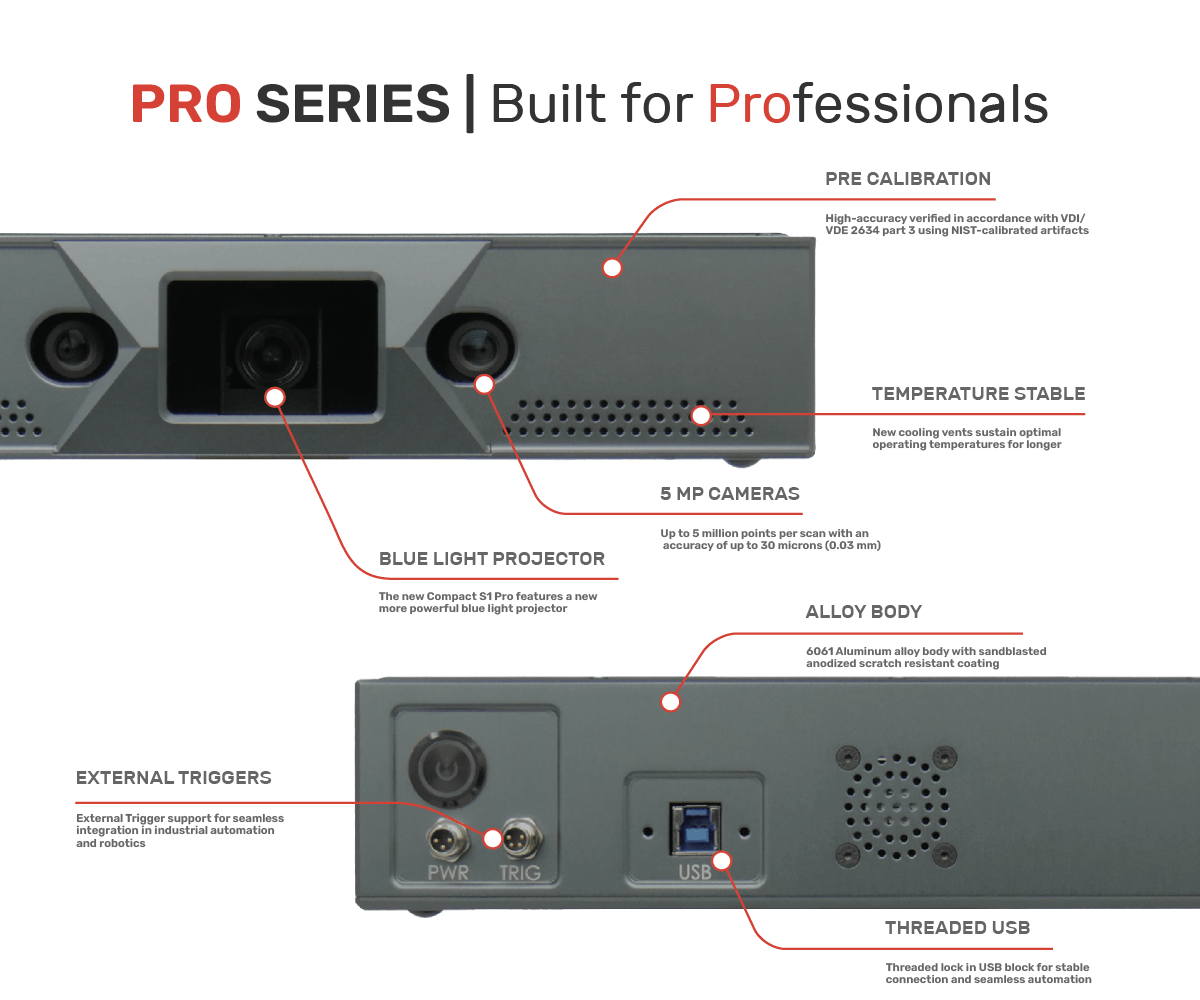

When considering various options, it’s worthwhile to check for scanners made from robust materials, such as aluminum alloy. These materials don’t just ensure that the device stands the test of time, but they also ensure optimal performance throughout its lifecycle.

Moreover, the nitty-gritty details can make a substantial difference. Features such as scratch resistance or efficient cooling systems can often be overlooked but play an essential role in ensuring a device’s longevity.

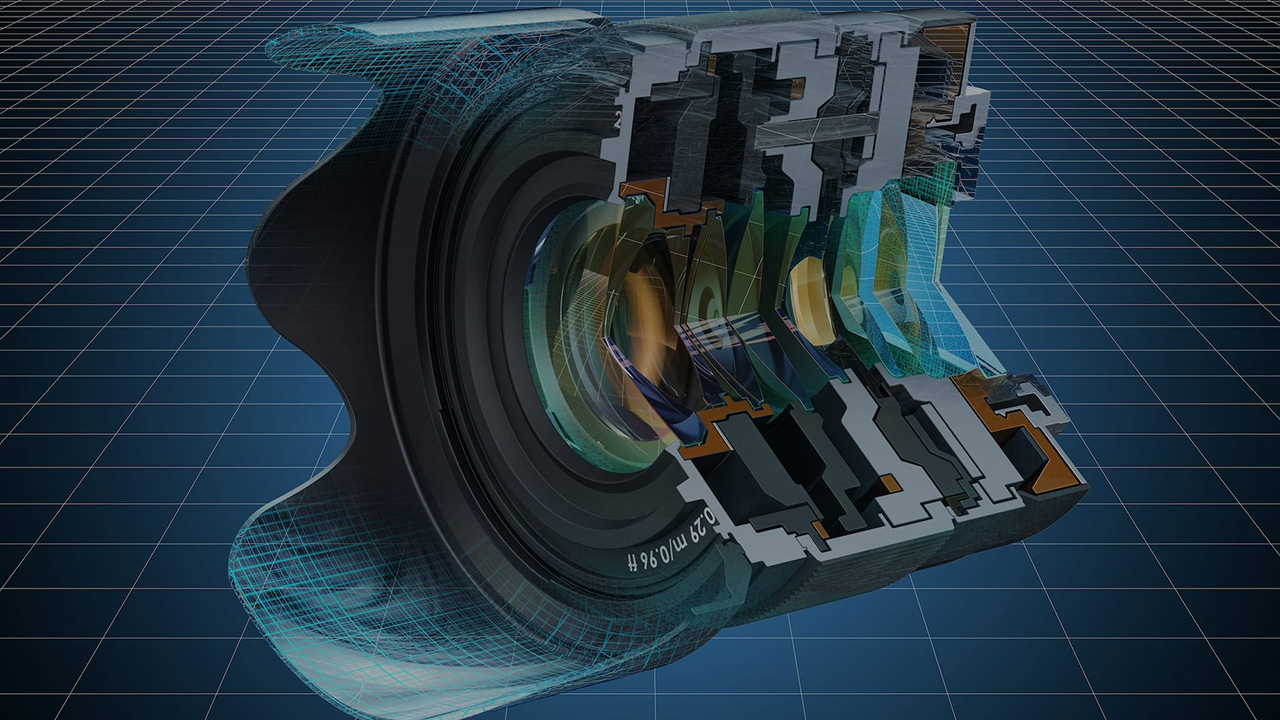

3. Image Quality: Beyond Just Resolution

In the world of 3D scanning, the term ‘image quality’ transcends mere resolution. It encapsulates the marriage of superior hardware and sophisticated software to guarantee high-fidelity data capture. Dual 5MP camera systems, for instance, have become a sought-after feature, primarily because they ensure the capture of even the most intricate details.

However, it’s not just about the camera. The symbiotic relationship between the hardware and the software plays an equally pivotal role. Seamless integration ensures that the data captured is not just detailed but also accurate and ready for further processing or application.

4. Lighting System: Illuminating the Future

One of the lesser-known yet critical advancements in modern 3D scanners is the shift in lighting systems. Moving away from traditional white light sources, the industry is rapidly embracing more advanced options, such as blue light projectors.

The reason for this shift is simple: blue light offers clearer scans with significantly reduced noise and interference. This means that engineers can expect more accurate results, especially in challenging conditions or with complex materials.

5. Accuracy and Precision: The Heart of 3D Scanning

High-resolution imaging is a feather in a scanner’s cap, but the true essence of 3D scanning lies in its accuracy and precision. Some industry frontrunners, like the S1 Compact Pro Series, have taken this to heart, incorporating state-of-the-art image-processing platforms that stand up to rigorous industry standards.

When considering a scanner, it’s essential to look beyond just the resolution and dive deep into its accuracy metrics. How does the scanner fare when reproducing intricate details? Is the data consistent across various scans? Answers to these questions can make or break a reverse engineering project.

6. Automation Capabilities: Preparing for the Future

When considering a scanner, it’s essential to look beyond just the resolution and dive deep into its accuracy metrics. How does the scanner fare when reproducing intricate details? Is the data consistent across various scans? Answers to these questions can make or break a reverse engineering project.

Choosing the ideal 3D scanner for reverse engineering is indeed a challenging endeavor. While tools like the Compact S1 Pro offer a compelling package, it’s crucial for engineers to holistically consider their unique requirements against the features discussed above.

The right 3D scanner can revolutionize reverse engineering projects, making them more efficient, precise, and in line with the industry’s demands. As technology continues to advance, making an informed decision now will ensure that you remain at the forefront of innovation and progress.

Credits: Polyga

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.