8tree’s dentCHECK inspection tool is being utilized at Boeing’s 787 production facility in North Charleston, South Carolina, to help ensure the quality of fuselage sections prior to final assembly.

CONSTANCE, GERMANY & RANCHO CUCAMONGA, CALIFORNIA, MAY 2, 2024

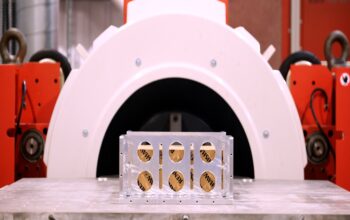

In collaboration with Boeing, 8tree’s dentCHECK tool, initially developed for and heavily used within the MRO sector for dent-mapping, was adapted by Boeing for use as an initial inspection tool. Boeing uses the dentCHECK tool to check the 787 fuselage skin for nearly microscopic anomalies in flatness.

Arun Chhabra, CEO at 8tree, said: “At 8tree, we continue to address a broad array of surface quality improvements across the aerospace supply-chain, empowering technicians and engineers to efficiently make more informed decisions about airframe integrity.”

The dentCHECK platform is the world’s only handheld-portable, completely wireless 3D scanner tool with integrated AR that is purpose-built for the aviation maintenance industry and recognized by all major aerospace OEMs for use by their respective airline operators. It can also be found integrated into drones and robotic automation cells. Leading Airlines & MROs across the Commercial, Military, Cargo and Business aviation sectors use 8tree’s dentCHECK tool and 8tree’s dentCHECK-as-a-service for mapping aircraft damage and creating detailed SRM-compliant digital damage reports.

With integrated AR, dentCHECK empowers the aircraft technician with instant, actionable measurements while boosting consistency (18x), accuracy (20x), efficiency (90% time-savings), and eliminating human subjectivity, compared to traditional manual inspection methods. dentCHECK delivers precision measurements ‘as simple as taking a photo’, and enhances safety through an improved understanding of airframe reliability.