This collaboration has brought a new set of Mastercam turning strategies, which supports Sandvik Coromant CoroTurn® Prime inserts and the PrimeTurning ™ technology.

A closer look at the integration of Sandvik Coromant’s PrimeTurning™ into Mastercam®

The convergence of advanced technologies and innovative machining methods has paved the way for significant advancements in manufacturing. One such integration is the Sandvik Coromant PrimeTurning™ with Mastercam® CAD/CAM software.

Mastercam ®, renowned for its comprehensive suite of CAD/CAM software solutions, has long been one of the go-to choices for manufacturers seeking efficient programming and optimization tools. This integration takes Mastercam’s capabilities to new heights to simplify CAM programming which can increase productivity 50-80% – all to benefit high material removal rates and extending the tool life by double vs using current standard inserts on the market.

Main benefits

- Enhanced productivity: The integration of Sandvik PrimeTurning™ with Mastercam ® streamlines the manufacturing process, enabling operators to achieve higher productivity levels. The PrimeTurning™ method’s unique approach allows simultaneous turning in all directions, eliminating the need for multiple tool changes and reducing machine idle time. This optimization significantly enhances production throughput, resulting in shorter lead times and improved overall efficiency.

- Improved Tool Life and Durability: The integration also introduces Sandvik’s innovative cutting tools into the Mastercam® system. Sandvik Coromant is renowned for its expertise in designing high-performance tools that deliver superior cutting performance, extended tool life, and exceptional surface finishes. By incorporating these tools within the PrimeTurning™ method, manufacturers can achieve significant improvements in tool life and durability, reducing tooling costs and enhancing overall process stability.

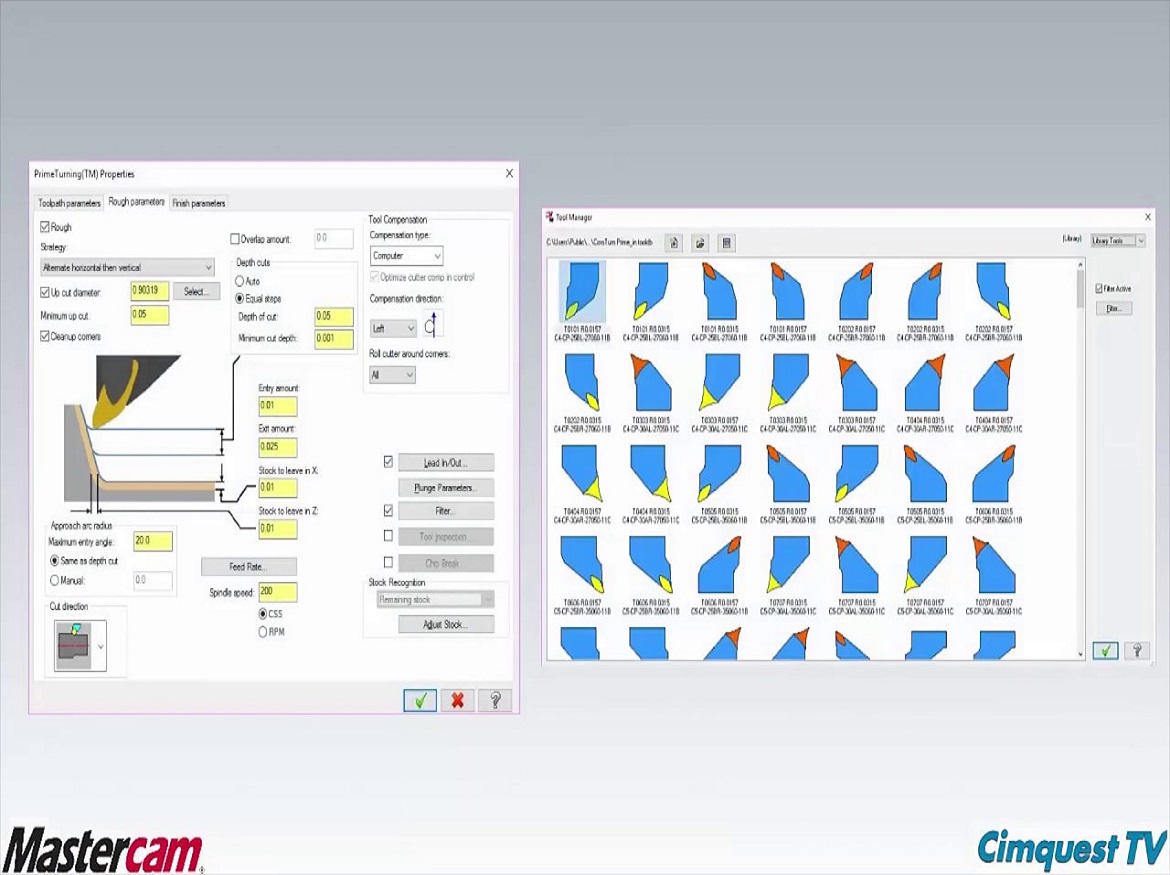

- Simplified Programming: The user-friendly interface Mastercam® offers combined with the integration of PrimeTurning™ makes programming and toolpath creation more intuitive and efficient. Operators can easily generate optimized toolpaths, taking advantage of the unique benefits offered by this new program feature. The seamless integration eliminates the need for complex programming techniques, reducing the learning curve for new users and enhancing overall workflow efficiency.

- Increased Flexibility and Versatility: The PrimeTurning™ method, integrated into Mastercam ®, allows for greater flexibility and versatility in machining operations. The ability to turn in multiple directions without requiring tool changes opens new possibilities for complex part geometries and reduces the need for specialized tools. This versatility enables manufacturers to expand their capabilities and take on a broader range of projects, resulting in a more competitive edge in the market.

- Enhanced Surface Quality: Achieving exceptional surface finishes is crucial in many manufacturing applications, and the Mastercam-Sandvik integration excels in this regard. The combination of Sandvik’s cutting tools and Mastercam’s advanced toolpath optimization algorithms ensures superior surface quality. This reduces post-processing requirements, saving valuable time and resources while maintaining the desired level of precision and aesthetics.

The integration of PrimeTurning™ into Mastercam ® represents a significant leap forward in precision machining capabilities. By combining the strengths of Mastercam’s CAD/CAM software and Sandvik Coromant’s cutting-edge tools, manufacturers can unlock new levels of productivity, efficiency, and versatility. The benefits of this integration are far-reaching, encompassing enhanced productivity, improved tool life and durability, simplified programming, increased flexibility, and exceptional surface quality.

“The Sandvik Coromant PrimeTurning™ method and new CoroTurn® Prime inserts represent a game-changing development for turning, and we’re thrilled to partner with Sandvik Coromant to help bring this innovation to the market,” says Meghan West, President and CEO of Mastercam.

Mastercam®

As an industry leader for more than 35 years, Mastercam takes pride in meeting the demanding needs of our customers by providing excellent products at affordable prices. We adhere to our strategy of combining superior software programming with practical shop floor experience. We have remained at the forefront of CAD/CAM technology by listening to our customers’ needs, being accessible, and most of all, being dedicated to our customers. Mastercam has provided CAD/CAM solutions to more than 250,000 installations worldwide in the moldmaking, automotive, aerospace, and consumer industries.

Learn more about Mastercam®

PrimeTurning™

Sandvik Coromant is part of the global industrial engineering group Sandvik. Sandvik Coromant is leading the way of manufacturing tools, machining solutions and knowledge that drive industry standards and innovations demanded by the metalworking industry now and into the next industrial era. Educational support, extensive R&D investment and strong customer partnerships ensure the development of machining technologies that change, lead and drive the future of manufacturing. Sandvik Coromant owns over 3100 patents worldwide, employs over 7,600 staff, and is represented in 150 countries.

Learn more about Sandvik PrimeTurning™