Measuring even a very large variety of workpieces does not necessarily have to involve a great deal of programming. A software project that Mahr has implemented for an Austrian manufacturer of standardized machine elements (standard parts) shows how it can be done quickly and easily.

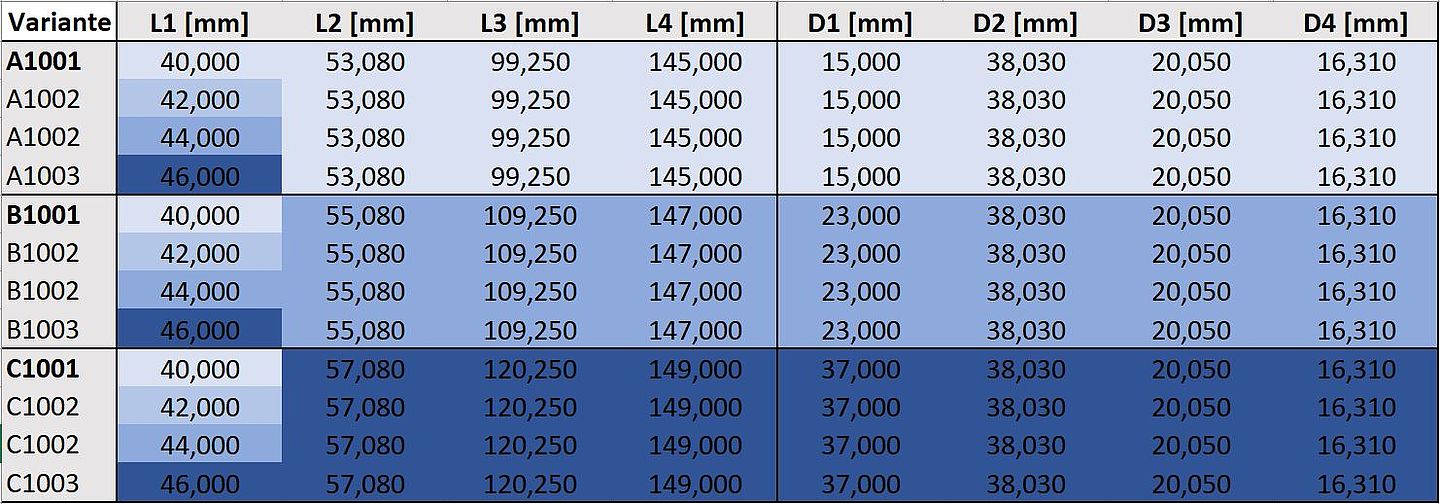

The initial situation was that the customer had around 4,000 different but similar rotationally symmetrical standard parts with a MarShaft Scope 750 plus. In theory, this would have required 12,000 MarWin EasyShaft programs. However, the software specialists at Mahr found another solution with the help of Excel.

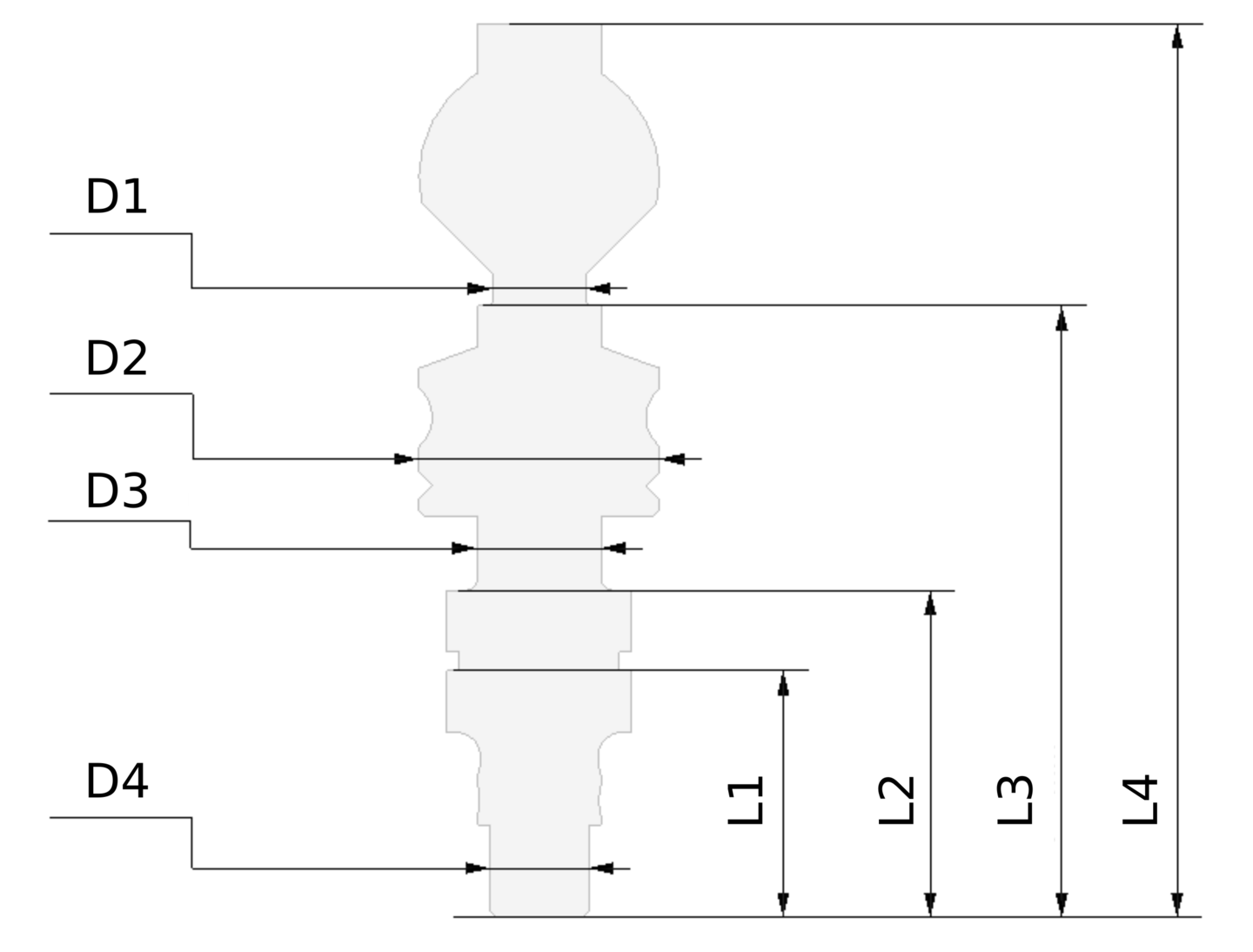

Illustrative example of a parameterized drawing

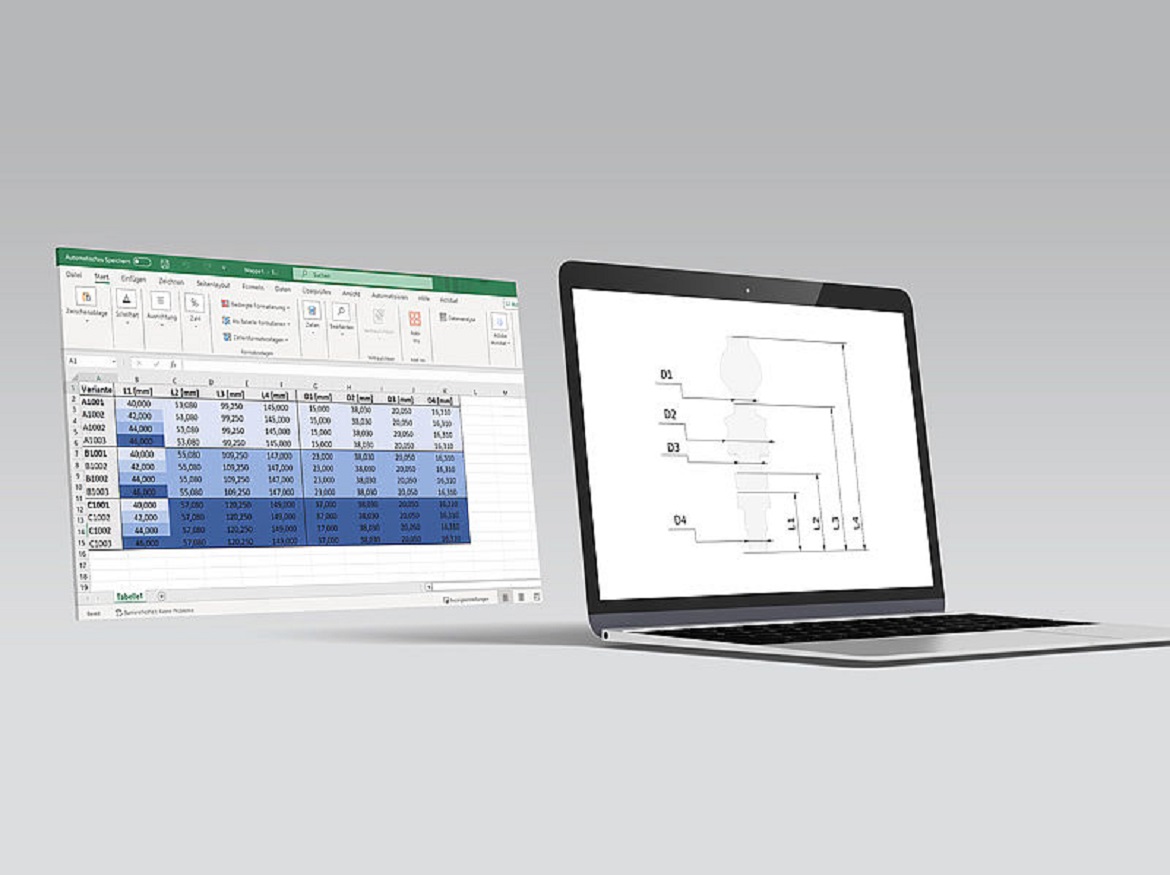

Parameterized programs

And this is how it works: The customer already had a database with the measured values of the 4,000 components. This database was read out via Excel as a table of workpiece characteristics. At the same time, the Mahr programmers created a template measuring program. This could then be multiplied over three processing steps in Excel for the previously read characteristics: MarWin EasyShaft was able to create a measuring program for each individual component automatically and without any extra programming effort. Optical diameters; distances to flat surfaces, radii and diameter transitions; radii, roundness and coaxialities were checked.

Basis for parameterized programs: Illustrative example of an Excel table with data from parameterized drawings

“With this solution, our customer only had to create around 20 parameterized programs,” says Stefan Lüders, application engineer at Mahr. “This saves him a lot of time while maintaining the high quality of the measurement results.”