At IMTS 2024, Renishaw will showcase a range of new products that deliver improved performance accuracy and repeatability, including a new line of products for industrial automation, and Renishaw Central, its new smart manufacturing data platform. As part of its Quality Assurance exhibit (Booth #134314), Renishaw will highlight capabilities that make it a trusted partner for innovation. The company’s AM solutions exhibit (Booth #433239) will feature Renishaw’s new TEMPUS™ technology and the new RenAM 500 Ultra metal AM system , designed to reduce build times by up to 50 percent.

Renishaw will demonstrate technologies that help increase manufacturing productivity, eliminate user error and improve production processes. This includes its new data-driven solution, Renishaw Central – a manufacturing connectivity and data platform that collates and presents data collected throughout manufacturing processes, enabling users to monitor and update machining and quality control systems. The data platform can digitalize, visualize and control manufacturing and measurement processes, and has helped Renishaw achieve a 69 per cent reduction in automation stoppages in its own machine shops.

Renishaw’s new product line for the industrial robotics market will also be on display at IMTS, aiming to transform the process of commissioning and servicing industrial robots. The product range includes three products: RCS L-90, RCS T-90 and RCS P-series, all supported by a dedicated software suite to help simplify robot set-up, health checks and recovery of robotic applications following collisions.

“Manufacturers worldwide — ourselves included — are facing multiple challenges to increase automation and become more productive, competitive and sustainable while overcoming skills shortages and major technology shifts in the automotive industry,” explained Dan Skulan, General Manager – Industrial Metrology at Renishaw Inc. “We’re looking forward to showcasing our wide range of technologies for smart manufacturing, process automation and increased digitalization around CNC machining. Visitors to our Quality Assurance booth at IMTS will discover our innovative solutions for shopfloor metrology and consolidating end-to-end process data for closed-loop CNC automation, manufacturing traceability and ongoing process and product optimization.”

At IMTS, Renishaw will also demonstrate how manufacturers can use tools to improve precision, speed and productivity at every stage of the manufacturing process, without compromising on accuracy. For example, the REVO® 5-axis multi-sensor system for co-ordinate measuring machines (CMMs) will be featured with its extensive range of probes for complex inspection applications. The system provides automatic switching between tactile scanning, touch-trigger, ultrasonic, vision and surface finish measurement. The system’s innovative design maximizes CMM inspection capabilities with patented 5-axis measurement technology to offer a future-proof inspection solution to manufacturers across multiple industries, including aerospace, automotive and medical.

For machine tool users, Renishaw will highlight the new RMP24-micro, the world’s smallest wireless machine tool probe, that measures just 24 mm in diameter and 31.4 mm in length. Designed for automated job set-up and inspection, it will appeal to manufacturers making high-value, high-precision miniature components, such as those found in the medical, watchmaking and micro-mechanics industries.

For visitors looking for machine calibration products, the latest update to the CARTO software suite (version 4.8) will also be on the stand, now featuring support for the Renishaw XM-60 multi-axis calibrator to enhance the monitoring of precision machinery. Also shown will be FORTiS™ enclosed encoders, which can help machine tool builders produce machines that meet high performance and environmental standards.

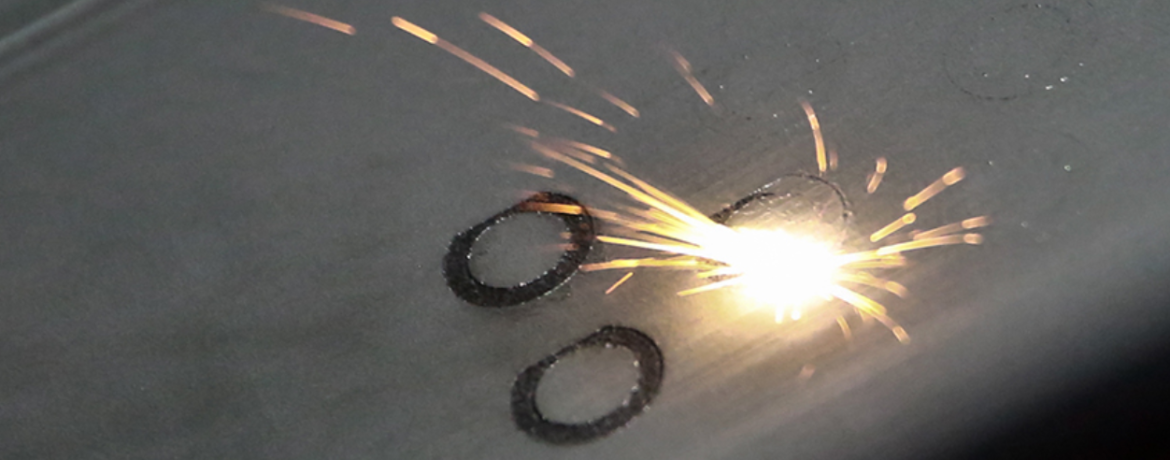

Renishaw’s AM exhibit will feature the new TEMPUS technology for metal additive part production. TEMPUS technology uses advanced scanning algorithms that sequence the layer data to maximize productivity while maintaining part quality. TEMPUS is standard with the new RenAM 500 Ultra system, as well as advanced process monitoring software. The combination of significantly reduced build times and detailed build insights means that the RenAM 500 Ultra delivers cost-effective, reliable additive manufacturing for metal component production. Existing RenAM 500 series customers can access TEMPUS technology as a paid-for upgrade, to make the most of their machine investment.

“Our success over 50 years has been built on providing robust and reliable products that solve manufacturing problems across a wide range of industry sectors,” explained Will Lee, Chief Executive at Renishaw. “We’re seeing customers struggle to reduce production errors and material waste, and wanted to provide them with automated tools to better connect data across the various production stages. That way, customers don’t need to compromise on speed, accuracy or flexibility. Our solutions can demonstrate the role of newer technologies, such as AM, in the future of manufacturing and how its technologies can help meet sustainability goals.”