Introduction

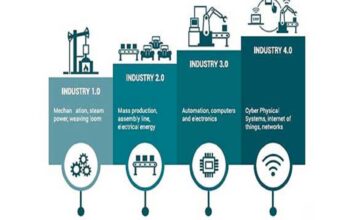

Sand Casting is a time-honoured manufacturing process, notably in the Oil and Gas, Heavy Machinery, and equipment manufacturing industries, where part size is often large and complex, with weight running in tons. The complexity of parts in this process demands a systematic approach with skilled individuals at each stage. However, in the last few years, Steel casting industry has been challenged with diminishing skilled manpower, leading to a global decline in production across renowned foundries.

Enter Additive Manufacturing particularly Binder Jetting, popularly known as Sand 3D Printing offers fresh perspective to technocrats in the conventional manufacturing industry. Integrating 3D Printing with traditional casting offers multitude of benefits such as enhanced design flexibility, consolidated core designs, accelerated production times and significant reduction in resources and costs, improved product quality, optimized part weight. Also, this innovation has thus sparked creativity among enthusiastic innovators and engineers to explore new possibilities.

The technology is finding traction in the foundries, especially in crafting complex components such as turbine casings, pump casings (including multi-stage pumps and double volute castings) and others. For example, manually cast intricate pumps requires making and assembling numerous cores, demanding highly skilled manpower and significant time. Besides, assembly of cores with precision is labour intensive and impacts product quality. Tooling itself takes 6-10 weeks, and casting adds another 16-20 weeks, post-production challenges such as cleaning, fettling and grinding further adds time and resources.

The Peekay Steel Approach

To overcome these challenges, Peekay Steel Castings Pvt. Ltd., pioneers in steel casting adopted 3D sand printing technology. This approach not only saves time but also offers superior finish and accuracy. The company employs a hybrid manufacturing approach utilizing 3D printed sand cores in conventional Molds or printing the complete mould and core using 3D printing and subsequent processes to produce the castings, following the conventional casting approach.

Peekay Steel Castings proudly houses a VoxelJet VX4000 machine at their Additive Manufacturing and Engineering Centre of Excellence in Devanahalli, Bangalore. Equipped with advanced infrastructure, this set up facilitates seamless production of sand molds and cores. The foundry experts here have leveraged this technology to innovate new running systems, and even up to a stage where they have influenced the design and quality of the product working closely with the customer. Recently, the technology was adopted to manufacture a multistage pump (BB3) where the number of parts in the core was reduced from 32 to 2. Additionally, an efficient synthetic sands was chosen to maintain high standards of surface finish on the cast part, thereby minimizing surface finishing operations.

BB3 Multistage Pump

The direct printing of moulds and cores to manufacture cast the types of intricate pump has led to the elimination of draft allowances, thus minimizing material wastages. Moreover, with no tooling manufacturing time required, the lead time plummeted from 16 weeks to 10 weeks. The overall product quality significantly improved, with the surface finish of the cast part having an Ra value of 6.3 µm. This was achieved using Peekay’s in-house casting facility at Calicut which has a capacity to produce upto 15MT single piece weight castings of various alloys.

BB3 Multistage Pump – Cores

This successful development led Peekay to adopt the same technology in other critical components such as double volute pumps, turbine casings and many gas turbine components, where critical cores are manufactured with the hybrid approach. The company’s bold venture into this new manufacturing realm demonstrates the potential of blending traditional methods with advanced technologies.

Conclusion

This approach not only enhances efficiency and product quality but also supports rapid product development for after market segments too. In summary, the integration of Sand 3D printing with traditional casting has revolutionized manufacturing process at Peekay Steel Castings. This approach has addressed longstanding challenges, paving the way for more efficient, sustainable, and superior-quality manufacturing. As the industry continues to evolve, this hybrid approach promises continued innovation, driving the quest for excellence to new heights.