Detecting and Testing Electric Car Doors

Challenge

Overcoming Rigidity in Traditional Manufacturing

Solution

Precision and Adaptation: SolMotion Enhances Complex Assembly Processes

SolMotion Functions

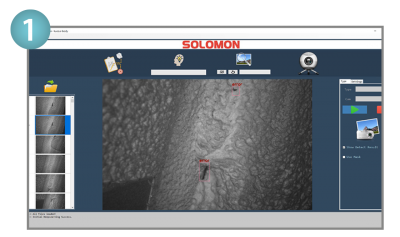

1. AI Deep Learning Tool

Neural networks train AI to recognize object features/defects on item surfaces. Unlike rule-based AOI, SolMotion’s AI inspection has broader, user-friendly applications without deep tech expertise. Paired with SolMotion’s vision-guided robot tech, a robot-mounted camera mimics human eyes, meticulously inspecting object surfaces.

Applications

- Painting defect and welding inspection

- Mold repair

- Metal defect inspection

- Food sorting

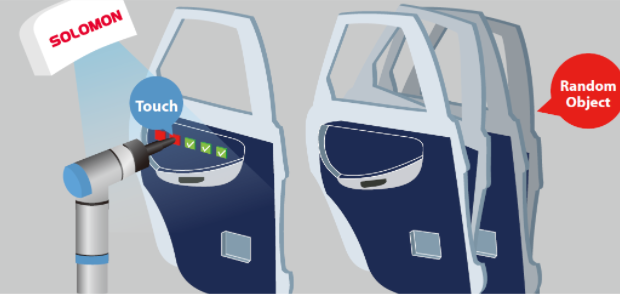

2. 3D Vision Positioning System

Objects can be placed randomly without precise fixtures, thanks to SolMotion’s AI-driven visual recognition of distinct features that accurately pinpoints their spatial positioning for real-time robotic processing. Additionally, the system’s path-loading function, rooted in object feature recognition, enables flexible production.

Applications

- Various machine tending tasks

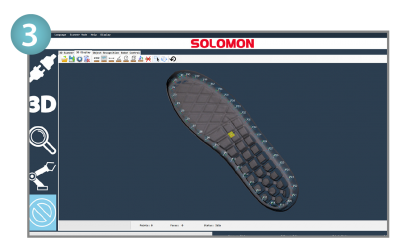

3. Robotic Path Planning Auto-Generation

No manual robot path setup is needed. Solomon’s AI learns environment edges for automatic path planning. Adjust processing angle as needed: “vertical” or a specific angle. Generate surface-filling paths, and optimize corner paths. Works with 20+ robot/PLC brands. Ideal for Hi-Mix/Low-Volume, variable path needs.

Applications

- Cutting

- Gluing

- Edge trimming

- Painting

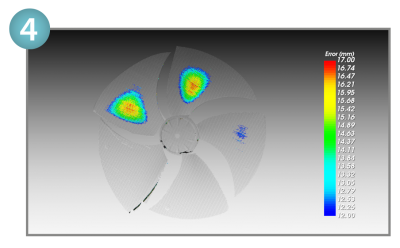

4. 3D Matching Defect Inspection

SolMotion instantly compares real-time 3D point cloud data with the standard CAD. It creates a report based on the set difference threshold, showing height, width, and volume variations. This data can auto-generate robot paths. Ideal for object matching and deformation compensation tasks.

Applications

- Inspection

- Trimming

- Repairing

- Milling

- 3D Printing