SmartRay, the leading manufacturer of 3D sensors that focus on metrology grade inspection through laser triangulation, is showcasing its latest developments and product launches at VISION 2024 from 8th to 10th October in Stuttgart, Germany.

Renowned as the most important international industry meeting point for computer vision technologies, SmartRay will be joining more than 400 exhibitors, demonstrating its latest developments in its cutting-edge ECCO X 3D sensors. These sensors provide a typical scan rate of up to 40 kHz.

Visitors to Stand 10E20 will see first-hand SmartRay’s new products with live demonstrations. These include the ECCO X 012 3D sensor offering an exceptional resolution of 0.3 – 0.4 µm (vertical), 2.7 – 3.2 µm (lateral) and a scan rate of up to 40 kHz which visitors will see through a demonstration of scanning injection needles with different diameters.

Also on display is the new ECCO X 025 Dual-Head sensor. Currently a prototype but in development for a 2025 release, this Dual-Head sensor provides high-speed, shadow-free scanning, which will be demonstrated on a ball grid array (BGA).

Finally, the new ECCO X 100 provides extraordinary speed and will demonstrate gap measurement which is widely used in the automotive industry and also in white goods manufacturing. The live demo will show two sensors with different laser wavelengths as the ECCO X 100 is available with 450nm (Brilliant blue) and 660 nm (red) featuring high dynamic range and image stitching.

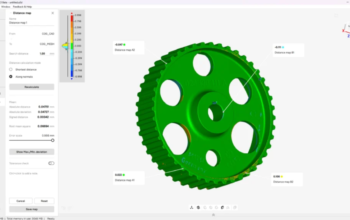

In addition, SmartRay will demonstrate JOSY, its weld inspection solution, by scanning a prismatic battery top weld, a crucial element in the production of batteries for electric vehicles. With an extraordinary inspection speed of less than two seconds and a reliable defect detection down to 0.1 mm, this solution is a true game-changer in this industry and demonstrates the already-proven intuitive result display of JOSY for rework and process optimization.

As well as standard sensors, SmartRay offers an OEM customisation service, tailoring advanced 3D inspection to meet individual requirements, from small specification changes to the development of highly specialised sensors for individual applications. Customers benefit from the highest resolution, optimum accuracy and best repeatability through this versatile approach. Speak with the experts on-site to tailor the sensor to your individual needs.

Clare Rathsack, Business Unit Manager ECCO from SmartRay said: “We are proud to launch our new 3D sensors at this key event for the image processing world. The smallest, most compact sensor in its class, our ECCO X range is revolutionising 3D inspection. With a wide range of fields of FOV models, ECCO sensors provide high-performance, high-resolution and flexible scanning, whatever your target requirements offering inline metrology and inspection”.