AI Cameras and EDAS

What are AI Cameras, and how do they differ from traditional cameras in industrial applications?

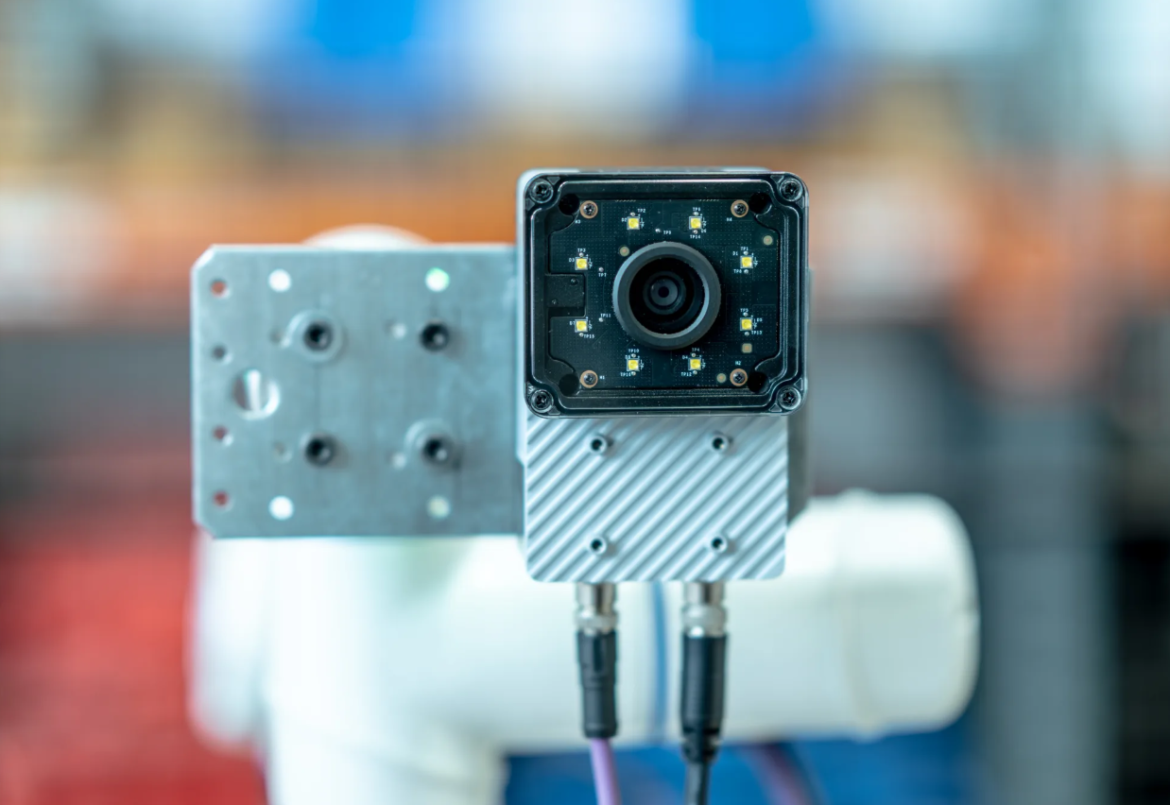

AI cameras stand apart from traditional industrial cameras primarily through their ability to self-learn. While traditional cameras require pre-programmed rules to detect pixel patterns, colors, or shapes, AI cameras can independently adapt and evolve. This means they can identify a wider variety of defects without the need for manual adjustments to brightness, angles, or settings.

AI cameras take the guesswork out of inspections, eliminating the need to fine-tune parameters for each new scenario. Their machine learning algorithms enhance their ability to spot anomalies—defects that may have otherwise gone unnoticed using conventional methods.

How do AI Cameras integrate with EDAS software for advanced metrology tasks?

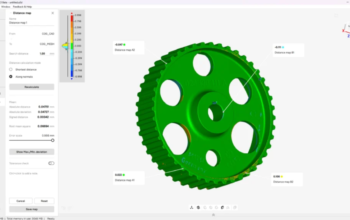

The integration of AI cameras with EDAS elevates quality control to the next level. Traditionally, 3D scanning technology was relied upon for detecting surface defects. However, AI cameras bring an additional layer of precision, identifying small imperfections that even 3D scans may overlook.

This combination of hardware (AI cameras) and software (EDAS) creates a powerful ecosystem. Operators can now benefit from an intuitive interface, flexible workflows, and efficient feedback loops. This results in smoother quality control (QC) automation and better communication between the operator, integrator, and QC department, making it easier to ensure consistent product quality.

How EDAS optimizes the functionality of AI Cameras

One standout feature of EDAS that maximizes AI camera efficiency is its simulation tool. For optimal image capture, a 2D camera requires precise positioning relative to the surface being inspected. Thanks to EDAS’s simulation capabilities, users can now generate the ideal camera angles and orientations with minimal effort. Simply position the robot tool above the target surface, or let EDAS’s path-planning features determine the best positions to capture all relevant features.

This innovation not only simplifies the setup process but also ensures that inspections are thorough, reducing the risk of oversight.

Reducing human error and increasing automation with AI Cameras

Incorporating AI cameras into automated workflows minimizes human error by standardizing inspection criteria. Once the system is set up, operators only need to define “go” or “no-go” conditions. The AI camera will consistently apply these criteria, ensuring that inspections remain uniform over time—unaffected by variables like operator fatigue, training levels, or personal bias.

Moreover, automation fosters a higher level of accuracy, as the AI system is constantly learning and improving. The result? A more reliable, error-free inspection process that contributes to overall product quality and safety.

Real-Time data processing for enhanced quality control

AI cameras shine in real-time data processing, providing several key advantages for quality control:

-

Larger Data Sets: AI cameras can process and analyze significantly more data than traditional methods, enabling more thorough and continuous monitoring.

-

Learning and Adaptation: The system gets smarter over time, learning from the data it receives and refining its defect detection capabilities.

-

Human-AI Collaboration: When the AI camera identifies defects with low confidence, human operators can intervene and provide feedback, refining the system’s understanding and improving its accuracy for future inspections.

This dynamic, real-time quality control system not only ensures immediate response to defects but also creates a continuous improvement loop, allowing the AI system to evolve alongside production requirements.

Key Benefits of Using AI Cameras with EDAS for Defect Detection and Analysis

The integration of AI cameras with EDAS unlocks several benefits that revolutionize defect detection and analysis:

-

Automated Inspection of Complex Parts: AI cameras can inspect intricate geometries that are difficult to assess through traditional methods, particularly parts that require analysis from multiple angles.

-

Efficient Data Acquisition: The synergy between AI cameras and EDAS enables rapid capture of high-resolution images, speeding up the data collection and analysis process.

-

Faster Model Training: The system supports accelerated model training due to the high-quality images it captures, leading to more accurate defect detection in less time.

-

Increased Accuracy Over Time: As the system collects more images for training, its accuracy continues to improve, enhancing the overall effectiveness of the quality control process.

How AI Cameras Support Industry 4.0 Objectives

AI cameras play a crucial role in the digitalization of quality control—a key aspect of Industry 4.0. By capturing high-quality images of defects and storing them on a digital platform, manufacturers can build a systematic repository of visual quality data. This shift from informal, subjective assessments to data-driven decision-making ensures greater consistency in quality evaluations.

Furthermore, as the AI models train on more data, they become better at identifying defects and their root causes. This self-sustaining cycle of improvement aligns perfectly with the goals of Industry 4.0, which emphasizes increased efficiency, automation, and the use of data to drive better outcomes.

Industries that benefit from AI Camera Integration

Industries like aerospace and high-precision manufacturing stand to gain the most from AI camera integration with EDAS. Both industries demand meticulous inspection of complex, high-value parts, where even the smallest defect can compromise product performance and safety. The ability to automate these inspections while ensuring accuracy makes AI cameras a game-changer for these sectors.

Future advancements in AI Camera technology and EDAS evolution

Looking ahead, AI cameras will continue to improve in speed, accuracy, and efficiency. Future models are expected to require fewer images for training while delivering faster results. Manufacturers that start building quality datasets today will be in the best position to take advantage of these advancements.

EDAS will evolve in tandem with AI camera technology, enhancing its support for future innovations and offering a scalable, modular approach for companies at different stages of automation adoption. Those who fail to adopt AI cameras risk falling behind, as their competitors leverage AI to achieve efficiencies that are currently unimaginable.

Conclusion

AI cameras, combined with the power of Eleven Dynamics’ EDAS platform, offer manufacturers a revolutionary approach to quality control. From automated defect detection to real-time data analysis, this technology creates a smarter, more efficient production environment. By embracing AI cameras now, companies can not only improve their current operations but also prepare for the future of Industry 4.0.