Efficient hydro part maintenance is essential to the overall operation of hydro power plants. It ensures the reliability and safety of these facilities, helping to prevent unexpected failures that could lead to costly downtime or accidents.

Advanced 3D scanning has become essential in the maintenance and repair of hydro parts, including critical components like turbines, pumps, and valves.

The Limitations of Conventional Maintenance Methods

In hydro systems, the complexity of parts can pose significant challenges. Standard measurement techniques frequently fall short, failing to capture the detailed shapes and features essential for effective repairs.

Manual measurement methods, while reliable in the past, can introduce errors, affecting both the quality of repairs and the overall efficiency of the hydro system. Additionally, the time required for these manual processes can be extensive, leading to costly operational downtime.

In an industry where quick turnaround is crucial, especially during component failures, the need for efficient and accurate repair methods is essential. This is where the benefits of 3D scanning become evident, providing a contemporary solution to challenges in hydropower part maintenance.

The Advantages of 3D Scanning Technology

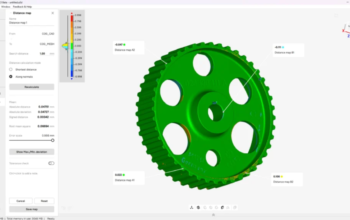

3D scanning allows for the rapid and precise capture of a physical object’s geometry. With advanced 3D laser scanners, engineers can quickly generate a digital model of a hydropower part, which can then be analyzed using 3D software.

This digital representation serves as an exact duplicate of the part, enabling in-depth analysis, modification, and optimization.

Precision and Detail

In hydro systems, the intricate geometries of components, such as the complex contours of turbine blades, the precision fittings of generator housings, and the detailed pathways within piping systems, can present substantial challenges during maintenance.

Standard measurement techniques often struggle to accurately capture these complex shapes and features. This lack of precision can hinder maintenance efforts, potentially leading to extended downtimes and increased operational costs.

One of the standout features of 3D scanning is its ability to deliver exceptional accuracy. Wireless 3D scanning system NimbleTrack can achieve an accuracy of up to 0.025 mm and maximum volumetric accuracy of 0.064 mm. NimbleTrack enables users to capture 3D data with meticulous details and industrial-grade precision.

Increased Speed and Efficiency

Another significant advantage of 3D scanning is its speed. Processes that once took days or weeks for manual measurement can now be completed in mere hours or even minutes.

For example, Scantech’s composite 3D laser scanner KSCAN-Magic delivers a measurement rate of up to 4.15 million measurements/s, which is efficient to capture intricate geometries, ensuring the digital model is generated fast.

By quickly obtaining detailed data, engineers can reduce downtime and expedite the maintenance process. This efficiency not only saves time but also enhances overall productivity, allowing hydro facilities to minimize disruptions.

Permanent Digital Records

3D scanning also facilitates the creation of lasting digital records of hydro parts. Once a component is scanned, the digital model can be stored for future reference.

This archive is invaluable for ongoing maintenance, as it provides a comprehensive record of the part’s condition and dimensions. Engineers can refer back to this data when making decisions about future repairs or replacements, ensuring informed and effective maintenance strategies.

Enhancing Repairs Through Reverse Engineering

The combination of 3D scanning and reverse engineering presents a powerful approach to improve repair and maintenance processes.

Reverse engineering involves dissecting a physical part to gain insights into its design and functionality, allowing engineers to develop new designs or repair existing components based on their findings.

By using 3D scanners, manufacturers can turn physical parts into computerized forms to carry out product development, design optimization and useful computational analysis.

Creating Accurate Replicas

When a hydro part sustains damage or becomes worn, reverse engineering enables the production of an accurate replica.

The 3D scan of the original component serves as the basis for fabricating a new part that meets or surpasses the specifications of its predecessor.

This process ensures compatibility and can lead to performance enhancements if design modifications are implemented based on the analysis.

Analyzing Component Design

Reverse engineering also allows for a comprehensive analysis of a part’s design, and performance traits.

For instance, if turbine blades are failing prematurely, a detailed examination can identify underlying issues, such as design flaws or material weaknesses.

This information is critical for creating more durable replacement parts, ultimately improving system reliability.

Custom Solutions for Unique Needs

Standard replacement parts are not always available or appropriate for every application. In such cases, the integration of reverse engineering and 3D scanning allows for customized solutions tailored to specific requirements.

This approach enhances overall performance and efficiency, ensuring each component functions optimally within its system.

A Practical Example: Overhauling Hydroelectric Turbines

To illustrate the impact of 3D scanning and reverse engineering, consider a hydroelectric facility dealing with turbine blade issues. Traditional repair methods may require the blades to be removed, manually measured, and then replaced, a process fraught with potential errors and delays.

By employing 3D scanning technology, the facility can quickly and accurately capture the geometry of the existing blades, including any signs of wear or damage.

The resulting digital model allows engineers to conduct a detailed analysis, pinpoint specific issues, and design new blades to maximize efficiency, minimize erosion and cavitation, as well as increasing the dynamic stability.

This streamlined process results in faster repairs and enhanced turbine performance, showcasing the effectiveness of integrating modern technology into traditional maintenance practices.

The Future of Hydro Part Maintenance

Looking ahead, the role of 3D scanning in hydro part maintenance is expected to grow even more pronounced. As technology continues to advance, the integration of 3D scanning and reverse engineering will become increasingly sophisticated.

Emerging innovations, including AI-driven analysis and advanced materials, will enhance the capabilities of these tools, resulting in even greater precision and efficiency.

In summary, 3D scanning and reverse engineering are poised to transform hydro part maintenance practices. By providing accurate measurements, accelerating repair processes, and enabling customized solutions, these technologies are setting new benchmarks for the industry.

The ongoing convergence of digital and physical realms will drive continued innovation, ensuring that hydro systems remain efficient and dependable for the long term.

Organizations that embrace these advancements will be better equipped to tackle the complexities of modern hydro part maintenance, ultimately delivering reliable energy solutions.