The new software product family for data exchange and process management in metrology

- closes the gap between application and reporting software

- centralizes quality data management globally

- enables effective collaboration across locations and provides valuable insights

Seamless integration

Seamless integration is key for global workflows: ZEISS CONNECTED QUALITY is integrated in our application software. Metrology projects are always synced, no additional workspace is needed. The product family is intended for customers with a broad metrology landscape – no matter which system or software. The server-based solution can be integrated in the customer’s IT landscape and offers additional control and security with the comprehensive roles and rights management, the logging of all changes and automated notifications. This simplifies audit processes.

“With ZEISS CONNECTED QUALITY, we enable agnostic, traceable, secure and global quality processes, offer access to system health and utilization data. This is the central collaboration platform for all global quality operations. By adding this completely new layer of data management to our software offering, we enable our customers to scale their leading quality capabilities globally”, says Christoph Grieser, Head of Global Software Sales at ZEISS Industrial Quality Solutions.

ZEISS CONNECTED QUALITY centrally connects systems and operators and offers three independent products for working with measuring systems and process data.

Manage your quality data and operations

ZEISS CONNECTED Inspection is the solution for global inspection management. It allows central planning, releasing and approving of inspection plans and results in one central place. Efficient collaboration, decision-making and alignment across teams or even companies becomes possible, for example global digital assembly projects.

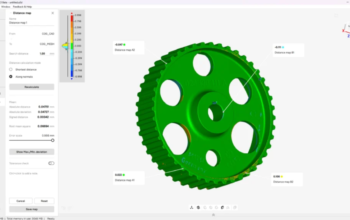

Monitor your measuring systems

The whole product family is hardware and software agnostic and is therefore particularly interesting for customers with a heterogenous metrology landscape. ZEISS CONNECTED Telemetry enables efficient system monitoring across all technologies and systems in just one dashboard.

Access raw data from your systems

With ZEISS CONNECTED Telemetry Data we provide access to our measuring systems’ raw data for the first time relying on the OPC UA standard. This is interesting for customers who want to use system data in a system of their choice or unlock totally new use cases like AI applications.

ZEISS CONNECTED QUALITY was presented to the public for the first time at the ZEISS Quality Innovation Summit in Berlin, where more than 1500 industry experts from around the globe came together to discuss quality challenges and trends. ZEISS Industrial Quality Solutions presented more than ten new launches at this event, ZEISS CONNECTED QUALITY being one of them.