Precision Meets Automation

In the age of Industry 4.0, the demand for precision, flexibility, and efficiency in manufacturing is higher than ever. To meet these challenges, Eleven Dynamics has joined forces with Nebotix and API, bringing together cutting-edge technologies in robotics, metrology, and software to provide a turnkey solution for automated large-part measurement.

The Challenge of Precision in Large-Part Measurement

Industries such as aerospace, automotive, and heavy manufacturing often deal with large components requiring meticulous measurement and inspection. Traditional methods are labor-intensive and prone to inconsistencies, especially as parts grow in complexity and size. The limitations in manual measuring—such as extended setup times, significant labor requirements, and the risk of human error—present a pressing need for a solution that can automate this process with high repeatability and accuracy.

A Three-Partner Solution for Unmatched Measurement Capabilities

In a recent collaboration, Eleven Dynamics, Nebotix, and API presented a fully integrated solution that addresses these needs:

- API’s 9D Ladar: API’s laser scanner system offers non-contact, high-precision measurement across distances up to 25 meters, ideal for scanning large components without sacrificing accuracy.

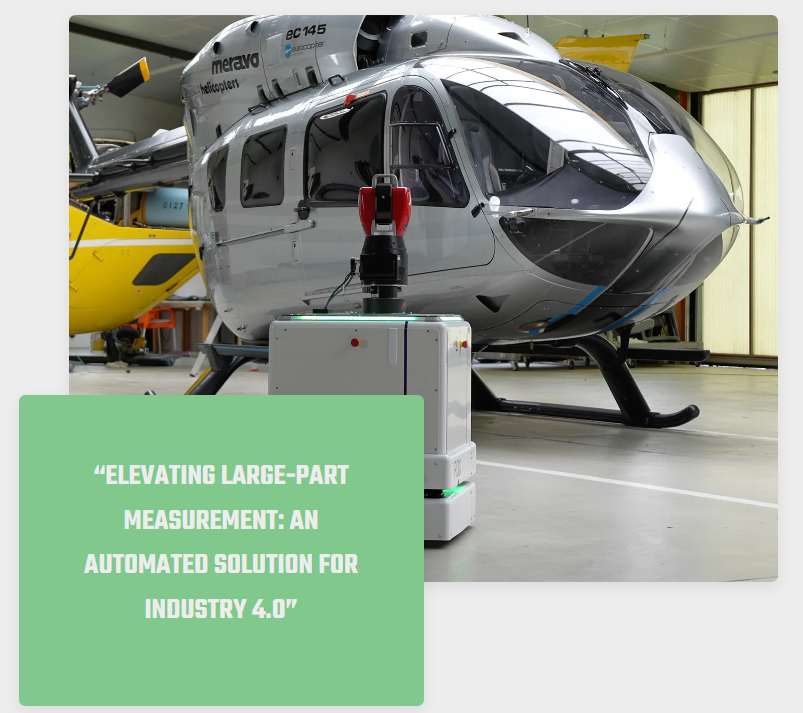

- Nebotix’ Mobile Robots: To maximize the coverage and flexibility of API’s scanning capabilities, Nebotix provides autonomously guided robots (AGVs and AMRs) that transport the laser scanners around the component, eliminating blind spots and enabling complete measurement from multiple angles.

- Eleven Dynamics’ Automation Suite: The Eleven Dynamics Automation Suite serves as the system’s brain, seamlessly coordinating the robot’s movement, the scanning process, and the collection of measurement data. It also includes simulation capabilities, enabling digital twin modeling and virtual setup of each measurement task, reducing real-world setup time and ensuring precision.

Key Benefits: Flexibility, Consistency, and Ease of Use

The synergy between these three systems results in a solution that can autonomously measure complex parts with minimal human intervention. Here are the primary advantages:

- Flexible and Scalable Measurement: With Nebotix’ modular robotic platform, the API scanner can navigate around large components or confined areas with ease, adapting to different use cases and enabling measurement of complex geometries.

- Improved Consistency and Repeatability: By replacing manual measurement processes with fully automated scanning, this solution reduces the influence of human error and delivers repeatable, consistent results every time.

- User-Friendly, Digital Setup: Eleven Dynamics’ software suite allows operators to configure and simulate measurement tasks virtually. Users can adjust scanning paths, specify measurement points, and validate system accuracy without physically interacting with the equipment until the automated measurement begins.

- 24/7 Operation for Enhanced Productivity: With autonomous robots and robust software, the system can run continuous shifts, providing non-stop inspection capabilities that help reduce cycle times and maintain production schedules.

Implementing the Solution: Simple Setup, Advanced ROI

Setting up the solution is as straightforward as defining the measurement features on a CAD model, configuring the AGV’s paths, and simulating the scan. Once these are fine-tuned in the virtual environment, the process can seamlessly transition to the physical production floor. The digital twin functionality allows companies to calculate cycle times, evaluate return on investment, and ensure that each measurement task is optimized for time and resource efficiency.

Redefining the Role of Metrologists in Industry 4.0

This solution not only addresses the demands for automated, consistent measurement but also redefines the role of metrology professionals. Rather than spending hours conducting manual measurements, specialists can focus on strategic tasks such as system configuration, data analysis, and process optimization. By removing the repetitive elements of measurement, this collaborative solution maximizes the value of human expertise while improving overall system productivity.

Looking Ahead: Future Applications and Expansion

The flexibility of this system allows for future adaptability, whether by adding new sensor types, integrating more advanced robotics, or expanding software capabilities. This collaboration is paving the way for a future where automated large-part measurement becomes a standard in manufacturing, offering companies a scalable, versatile solution that can keep pace with evolving production demands.

Conclusion

In today’s fast-paced industrial landscape, manufacturers need solutions that provide precision, flexibility, and efficiency without compromise. This joint approach by Eleven Dynamics, Nebotix, and API is a testament to how powerful cross-industry partnerships can drive innovation and deliver transformative results. By automating large-part measurement, we’re not only enhancing production capabilities but also setting new standards for quality and consistency in the digital age.