In an era where industrial smart manufacturing and digital creation advance in parallel, the innovation of productivity tools directly determines the leap in innovation efficiency and the breakthrough in the value of outcomes. Traditional 3D scanning, limited by cumbersome marker-based operations, insufficient adaptability to the environment, and complex scanning tasks, often becomes a critical shortcoming that constrains project timelines and the realization of creative ideas.

The 3DeVOK MT professional 3D scanner, inheriting the industrial genes of ScanTech, redefines the boundaries of productivity tools with its core technology: a fusion of 34-line blue laser, 22-line infrared laser, and large-area infrared speckle light sources. This scanner not only undergoes a dual upgrade in hardware and software but also streamlines complex scanning tasks into a “one-click” operation, from acquiring 3D point cloud data to outputting common 3D mesh file formats. It liberates 3D engineers, designers, and researchers from time-consuming procedures, allowing them to focus their energies and time on the act of creation itself.

3DeVOK MT Equipment Structure

3DeVOK MT Equipment Structure

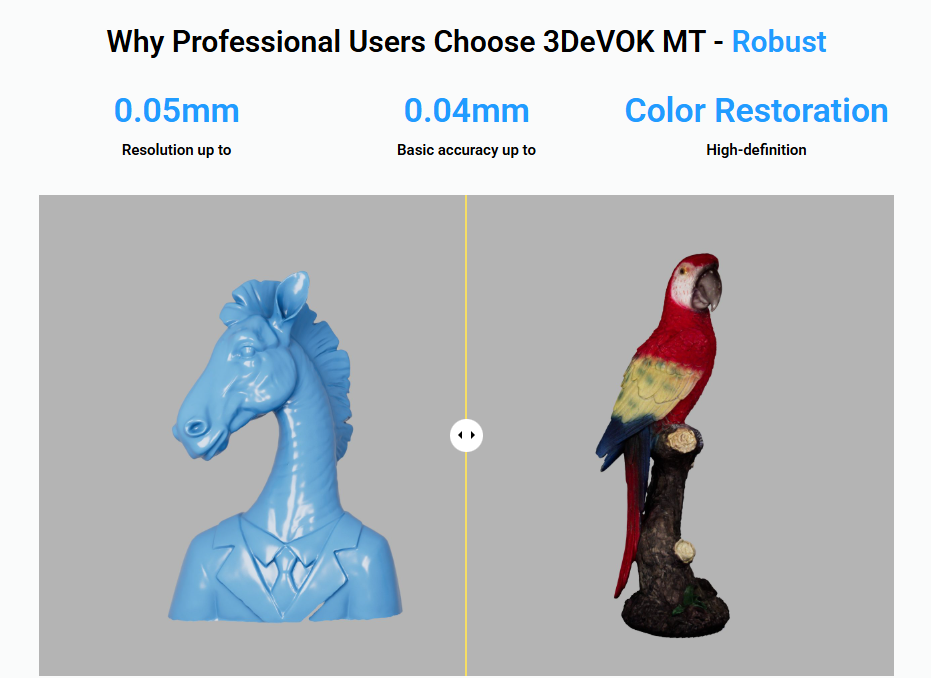

Core Advantage: Data-Driven Exceptional Performance

Efficient Scanning

– Rapid Acquisition: In laser mode, the scanner achieves a peak scanning speed of 4,500,000 points per second, with a frame rate of 70 FPS. The maximum single-frame scanning area can reach 490 mm × 490 mm, significantly enhancing efficiency.

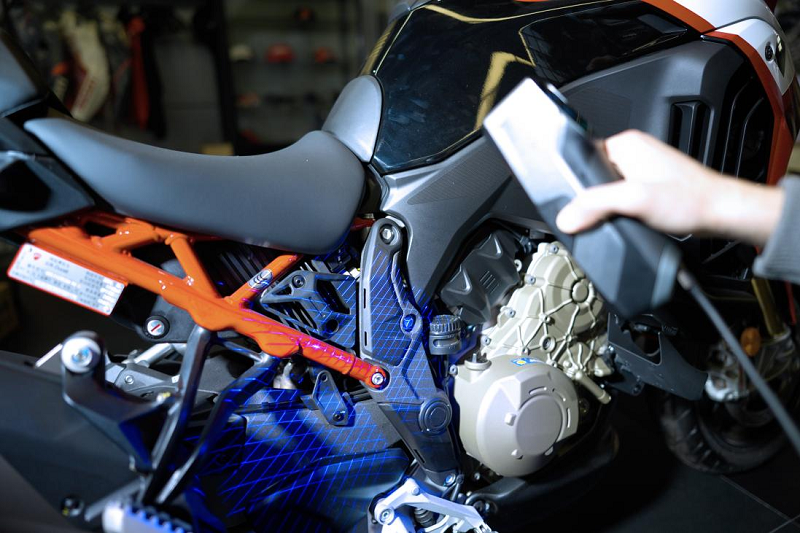

– Marker-Free Scanning: All three light source modes (blue laser/infrared laser/speckle) support marker-free or minimal marker scanning. For objects with rich textures or geometric features, a complete 3D model can be rapidly acquired without applying tracking points.

– Advanced Hybrid Alignment: Integrates multiple alignment methods, including texture, geometric features, and marker-based alignment.

High Precision

– Exceptional Resolution: With a maximum resolution of 0.05 mm, it captures intricate surface details and complex geometries. Volumetric accuracy reaches 0.04 mm + 0.06 mm/m (in marker-based alignment mode), meeting stringent requirements for industrial reverse engineering and precision component inspection.

– Vivid Color: 24-bit high-definition color scanning, combined with high-resolution cameras and texture displacement technology, accurately replicates object textures and colors, supporting applications in artistic design, cultural heritage digitization, and full-color 3D printing.

Reliability

– Multi-Size Compatibility: Capable of scanning objects ranging from 0.05 m to 5 m, from micro precision parts to large industrial components, it accurately captures details to meet cross-scale modeling needs.

– Environmental Adaptability: Breaking through environmental limitations, it can efficiently complete scanning tasks indoors, outdoors, in dark environments, or under direct sunlight. Adaptive light source technology ensures stable data collection.

– Material Versatility: Through the optimization of intelligent algorithms, it effectively handles complex surfaces such as black metals, highly reflective workpieces, dark hair, and multi-colored materials, eliminating scanning blind spots and enhancing data integrity.

Multi-Scenario Applications

– Industrial Reverse Engineering: Supports reverse engineering, automotive customization, and 3D printing. Compatible with mainstream CAD software (exports formats like *.asc and *.stl), with an accuracy of 0.04 mm accuracy and real-time mesh algorithms to accelerate product iteration.

– Art and Cultural Heritage: Light-free scanning mode combined with 0.1 mm resolution effortlessly captures dark sculptures and reflective artifacts, providing reliable data for restoration and digital preservation.

– Medical and Scientific Research: Utilizing eye-safe technology (certified by IEC 60825), it supports full-body scanning or partial scanning (with a maximum scan area of 1100mm x 1000mm), making it suitable for a wide range of disciplines including medical rehabilitation design and plant growth research.

– 3D Printing: With high-precision and high-efficiency 3D data acquisition capabilities and 24-bit high-definition color scanning, the 3D scanner can provide accurate 3D model data for 3D printing, precisely replicating object textures and colors. This meets the needs of reverse engineering for precision parts, art replication, and color 3D printing, facilitating efficient and high-quality 3D printing production.

Scan Now and Embark on a Journey of Creativity!

From reverse engineering of precision components to millimeter-level replication of cultural relics, from medical rehabilitation modeling to rapid inspection of large industrial parts, the 3DeVOK MT handheld 3D scanner harmonizes efficiency and precision with its 4,500,000 points/second scanning speed and industrial-grade 0.04 mm accuracy. Here, productivity is not merely a technical specification—it is the driving force behind every frame of data, accelerating the realization of creativity.