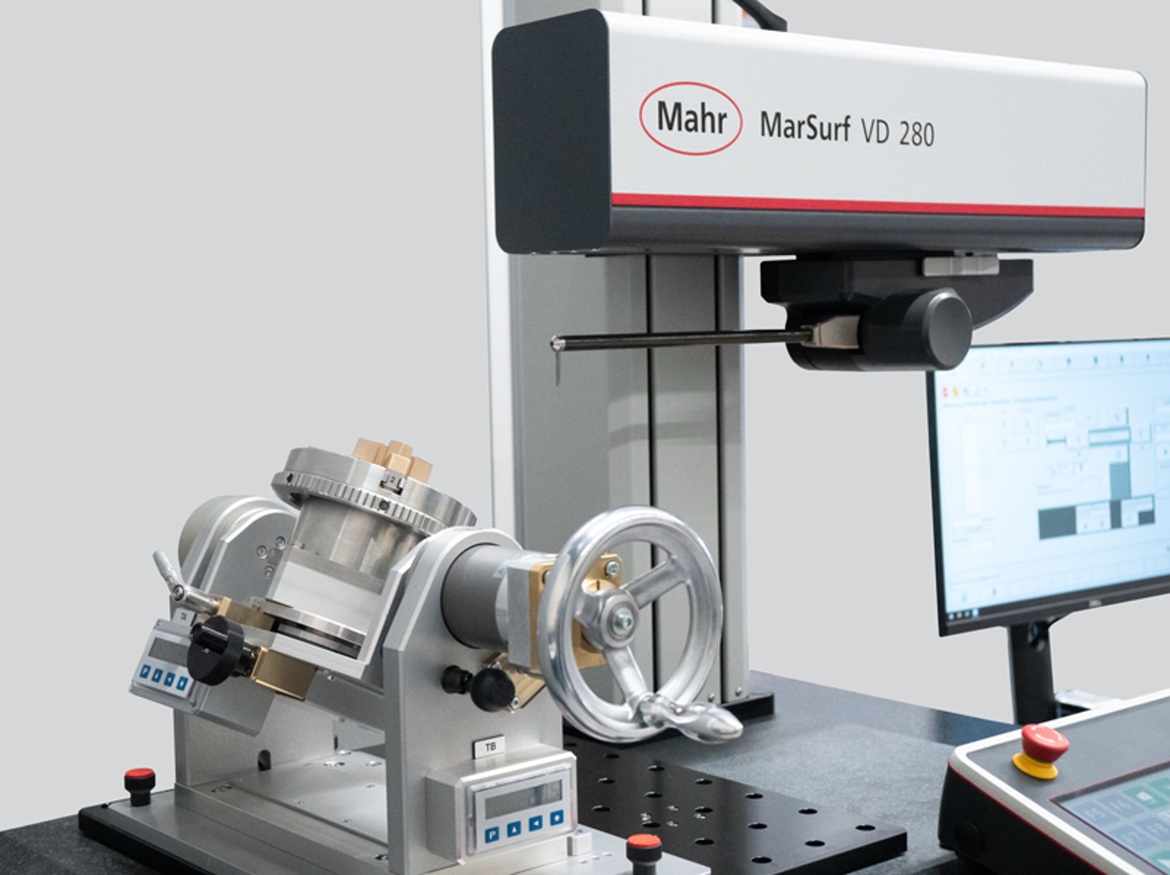

Like any other clamping device, the manual swivel unit can be mounted directly on the perforated plate of the measuring station. This allows the customer to add two rotation axes to the standard TY axis: the workpiece can now be positioned manually with extreme flexibility by swiveling (TB axis +/- 105 °) and rotating (TA axis = 360 °). Both axes have a digital display unit and can therefore be aligned with an accuracy of one tenth of a degree. This makes it easy for the customer to reach the desired measuring points and record the required measuring parameters quickly and, above all, reproducibly.

Set-up instructions for the operator regarding the required angular position of a measurement location can be stored in the Q&E measurement program, for example via illustrated pop-ups. The “MarSurf QE operator guidance” software option, which can be used to combine individual Q&Es created for each measuring location into an overall test sequence, is ideal for preventing several profiles with different angular positions but the same X and Z position from lying on top of each other in the evaluation area.

Suitable for all MarSurf measuring stations

The manual swivel unit can be attached to any standard measuring device in the MarSurf series. MES designs the clamping jaws individually according to customer requirements – depending on the workpiece geometry and clamping location. The customer can also choose the material of the clamping jaws according to their individual requirements. In this case, for example, it is made of bronze, a material that is somewhat softer and therefore particularly gentle on the workpieces. The client for this customer solution was a company in the automotive industry for a MarSurf VD 280 measuring station.

The customer benefits at a glance:

- Flexible positioning and therefore optimum accessibility to the measuring location

- Clamping jaws can be customized according to measuring task and customer requirements

- Suitable for all MarSurf standard measuring stations