The Problem

Manufacturers are facing unpredictable patterns in consumer demands, the pressure to improve productivity and quality control while reducing waste and costs, and even greater challenges with workforce availability. Vision AI enables manufacturers to improve the quality inspection process beyond the capabilities of conventional machine vision. Neurala VIA software brings

vision AI to the factory floor, without requiring an investment in new hardware, AI-trained personnel, or having to send data off-site.

How Neurala Addresses This Concern

• Saves Money: Neurala VIA works with any GigE Vision Camera, seamlessly plugging into

your existing production line using the cameras already in place.

• Saves Time: Set up a new inspection or modify an existing process in a fraction of the time of other solutions – and it can be done right on the line.

• Easy to Use: Our software walks you through all the necessary steps – you don’t need to be

a machine vision or AI expert to be able to use Neurala VIA.

• Flexible: Neurala VIA works with any controller that can communicate with Modbus

TCP (directly or through a gateway). And configurable Modbus outputs allow for easy

communication with PLCs.

• Installed on-premise: Keep control of your data – no need to have an external internet

connection.

• Minimal data required: Train with dozens, rather than thousands of images, collected directly from your manufacturing line.

Neurala VIA Implementation

Neurala VIA consists of two software programs, Inspector and Brain Builder, which can be

installed on any computer with as little as a CPU. It allows for seamless integration on the factory floor: collecting images from GigE Vision cameras and providing outputs over an industrial network (currently supporting Modbus TCP communication) directly to the PLC controlling the applicable machine.

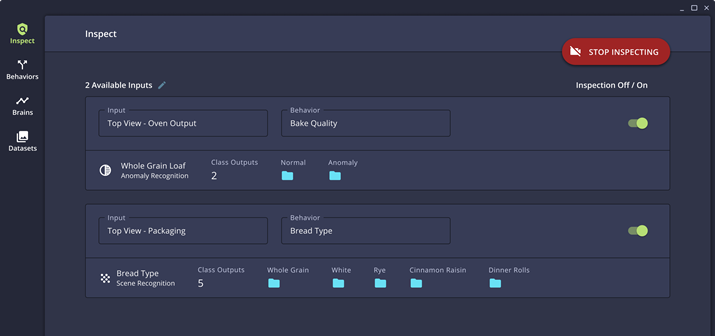

Inspector allows for fast and simple deployment of models created in Brain Builder on the factory floor. In this instance, an Anomaly Recognition brain is inspecting the surface of bread loaves in a commercial bakery for quality, and a Scene Recognition model is used later on in the process during packaging to determine which type of bread is being placed in trays to ensure proper packing and labeling.

Use Cases

Surface Inspection (e.g. bread, sheet metal, lumber)

For surface inspections on bread or other baked items, commercial bakeries look for color, shape, topping distribution, consistency, etc. Due to the complexity of the machine vision required to automate this process, inspection is often done by hand. For example, one out of every fifty trays is pulled off the line. This requires a full-time employee and disrupts the manufacturing flow. With a different person each shift, consistency is challenging, and rarely maintained.

Neurala VIA can automate the inspection process:

- Reduce reliance on scare workforce, require fewer employees on the floor

- Increase inspection (all product versus samples), leading to improved quality

- Improve inspection consistency

- Inspect on the line, no need to pull trays off and disrupt the flow

Component Inspection (e.g. electronics assembly, PCBA inspection)

Contract manufacturers produce a wide mix of PCBAs for their various customers. They manufacture assemblies, from creating the bare board, to final test. AOI machines (Automated Optical Inspection) are often used for quality testing. But AOI machines are slow, expensive, and require skilled programmers.

Neurala VIA can replace or complement existing solutions:

- Implement faster, with less expertise required – operators can program vision AI models

- Reduce cost: the equipment and the software are significantly less expensive

- Provide more flexible inspection options to their customer

- ROI: offer higher quality to the customer at a small increase in cost

Completeness/correctness check (e.g. case packing, kitting)

Case packing, such as cans placed in a cardboard box, are used for a wide of products such as pet food, canned vegetables, canned soup, etc. Different sized cans are packed in different trays, shrink wrapped, then sent to a palletizer. Commonly, visual inspection is done manually by an operator, but only when there are problems at the palletizer. Each case is inspected briefly to determine what is causing issues down the line.

Neurala VIA can automate vision inspection at the shrink-wrap station:

- Prevent downtime from issues with the palletizer due to improperly packed cases

- Increase inspection without increasing employees on the factory floor

- Adapt to fluctuating customer demands, product changes, or short-term promotions, creating new vision AI models on the fly from the factory floor while the line is running

Hardware Requirements and Performance Overview

| Brain Builder and Inspector | |

| Camera | GigE Vision Standard, up to 4 per install |

| Image Type | Color / Monochrome |

| Minimum Defect size for Anomaly | ~50 Pixels |

| Minimum number of images per class | As few as 50 images depending on the application |

| Acquisition Speed* | 100ms for 1 camera |

| Maximum Camera # | 4 |

| Operating System | Windows 10 (Linux support to follow) |

| GPU (Optional) | Nvidia GTX 900 series or better with min. 6GB of RAM |

| CPU | Intel i7, Xeon CPUs (Generation 6 or later) |

| Memory Requirements | 16GB RAM, 32 GB Storage |

| Communication Protocols | Modbus TCP Server (additional protocols to follow) |

| I/O | Configurable via network |

To know more, check Neurala.