GOM announces the new software solution GOM Volume Inspect offering innovative

volume visualization and inspection features for analyzing volume data collected

from any available computed tomography system (CT). It simplifies volume analysis

tasks significantly while giving deep insight on a part’s geometries, voids, or internal

structures as well as multipart assembly situations.

GOM Volume Inspect comes with a full 3D data analysis to evaluate a part’s quality and to

optimize the manufacturing process. As the software features a clever on-demand data

management concept, it delivers high performance at any time – even in case of huge volume data packages – and speeds up analysis processes.

Volume renderer and intuitive generation of sectional views

GOM Volume Inspect includes a powerful volume rendering function that visualizes the

whole part including the internal structures. Furthermore, the user can cut the object at any point and view it layer by layer in order to see the smallest details and gain in-depth information about the quality of the part.

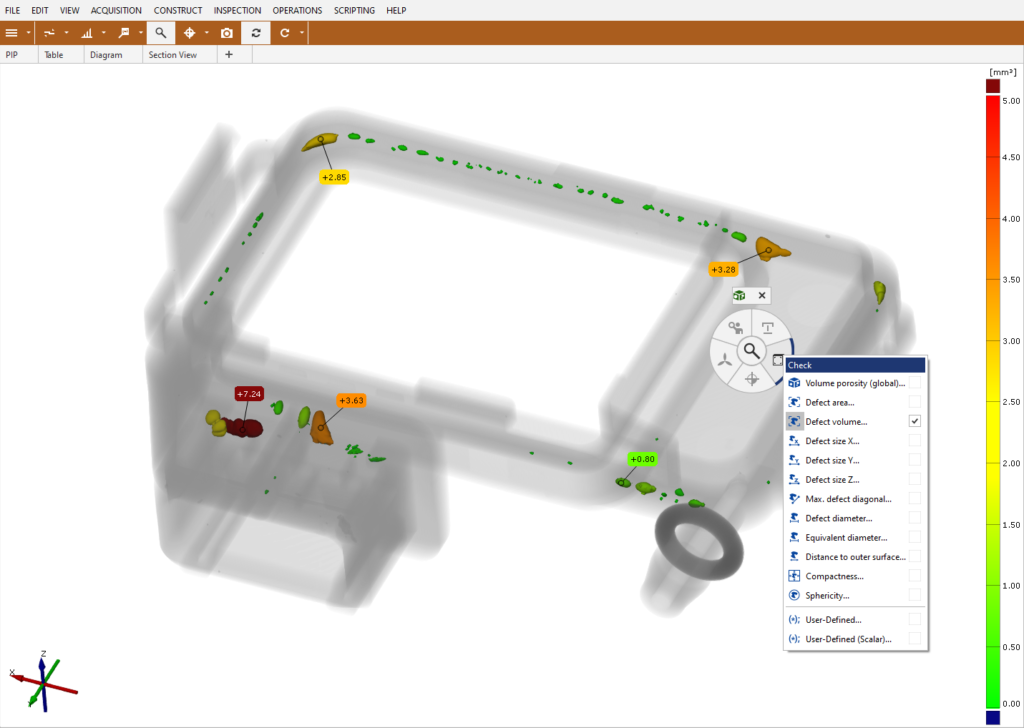

Wide range of analysis criteria and result presentation

The software also automatically detects any volume defect in a part, such as a shrinkage

cavities, and accurately evaluates the quality by checking defect dimensions including volume, diameter, and distance from outer casing.

Moreover, it is possible to evaluate the dimensions of CT volume data – be it full-field

evaluations, GD&T, or inspections of geometric dimensions on the outside of the part as well as on internal structures. GOM Volume Inspect walks the user through the complete analysis process and delivers the measured results in a transparent report with a single mouse click.

The report may include snapshots, images, tables, charts, text, and graphics.

Unique feature: trend analysis and part-to-part comparison

GOM Volume Inspect also includes a function that allows the user to load volume data of

several parts into one project, and execute a trend analysis on this data. This automated

comparison is a true advantage for quality assurance managers who measure parts on a

regular basis in order to derive a quality trend from the measurement data. The function also works on part-to-part comparisons, e. g. when comparing identical parts delivered from different suppliers.

Many volume inspection features for free

GOM Volume Inspect comes with a broad range of volume inspection functionalities for free, including 3D volume rendering, display of 2D volume slices as well as defect detection and visualization.

Additionally, the full version of the GOM Volume Inspect, providing the full extent of the above-described volume data analysis capabilities, is available as a free 30-day trial.

GOM Volume Inspect is part of GOM’s new software platform GOM Inspect Suite, that

embraces and facilitates the complete workflow from scanning to reporting for a maximum ease of use. With its all-in-one GOM Inspect software, 3D metrology specialist GOM has become the gold standard in many industries.

Captions

- Screenshot Shrinkage Cavities

The results can be shown in a clear color representation giving a good overview of the part. - Visual GOM Volume Inspect – Complete CT data analysis in 3D

To know more, check GOM.