With the rise of fully integrated and automated manufacturing processes the demand for compact shop floor in-process quality control, with closed-loop feedback, has never been greater.

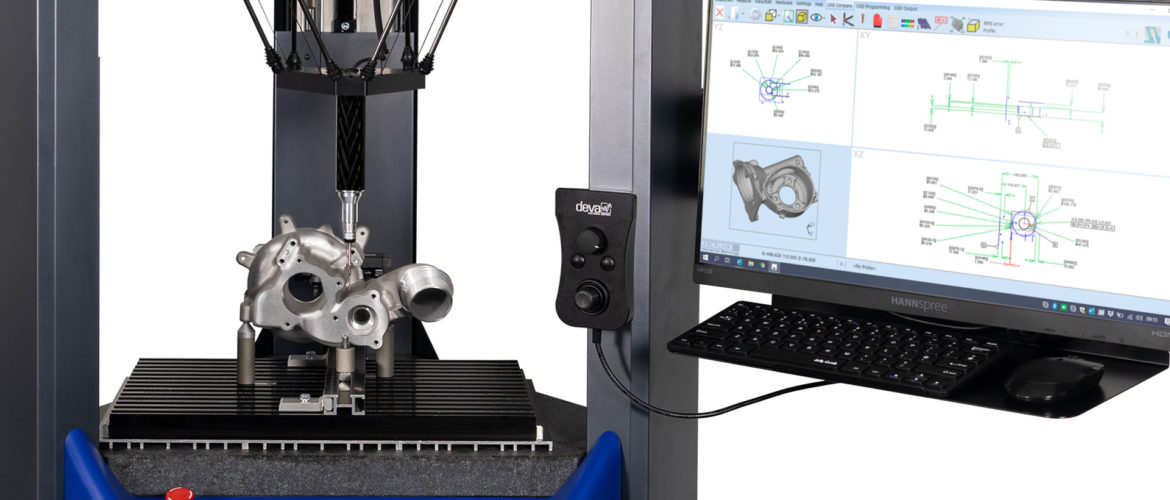

True to Aberlink’s heritage for innovation, the Extol is the world’s first CMM to utilize a delta mechanism. Designed for robustness and reliability, the Extol CMM will run around the clock making it ideal whether it is positioned next to a machine tool, in a manufacturing cell, or used in a dedicated inspection area.

The Extol is sold as standard with a Renishaw TP20 probe but is fully compatible with the TP200 probe. The TP200 uses strain gauge technology, so it does not exhibit lobing characteristics, making it ideal for high accuracy applications and when using longer styli. In addition, the TP200 probe has a longer touch-trigger life expectancy compared to the TP20, also making it ideal for automated and high-volume applications.

Five temperature sensors monitoring both the machine and ambient temperature ensure that the Extol is capable operating in uncontrolled environments, reporting measurements as though they had been taken at 20°C. The software will also produce a warning should the temperature change at a rate that is not conducive with reasonable metrology practice.

The Automatic Tool Offset Correction available within the Aberlink 3D software compliments the attributes of the Extol perfectly, enabling its utilisation as part of a fully automated production process in the most demanding manufacturing environment. With a larger measuring volume and smaller overall footprint than its predecessor, the Xtreme, the Extol CNC CMM can be positioned exactly where the measurement is needed.

The ergonomics of the Extol have also been a significant design factor. It is not only quick and easy to perform one-off inspections, but also has ample access for either batch inspection or to facilitate automatic loading.

The Extol will be supplied with Aberlink’s revolutionary Aberlink 3D measurement software. Widely regarded as the easiest to use software on the market, Aberlink 3D will construct a representation of a component on the monitor as it is measured. Dimensions between measured features can then be picked off and appear exactly as they do on the part drawing. The software incorporates GD & T dimensioning, RPS alignment and SPC data analysis. Further modules are also available for off-line programming of parts from a CAD model and also for comparing measured results to the CAD. Automatic shape recognition means the ‘smart’ software works intelligently to minimise operator input and improve efficiency and hence productivity and profitability. The simplicity of use allows even the most inexperienced of operators to use the Extol with the minimum of training, whilst the software contains all the functionality to satisfy even the most demanding of metrology requirements.

Customers of Aberlink CMMs are entitled to free-of-charge upgrades of their Aberlink 3D measurement software for the life of their CMM. The latest version of software is always available to download from Aberlink website and there are no software maintenance charges ensuring that the cost of ownership is also minimal.

Robust, accurate and reliable, the Extol CNC CMM is the perfect solution to automatically verify part quality for critical components.

To know more, please check Aberlink.