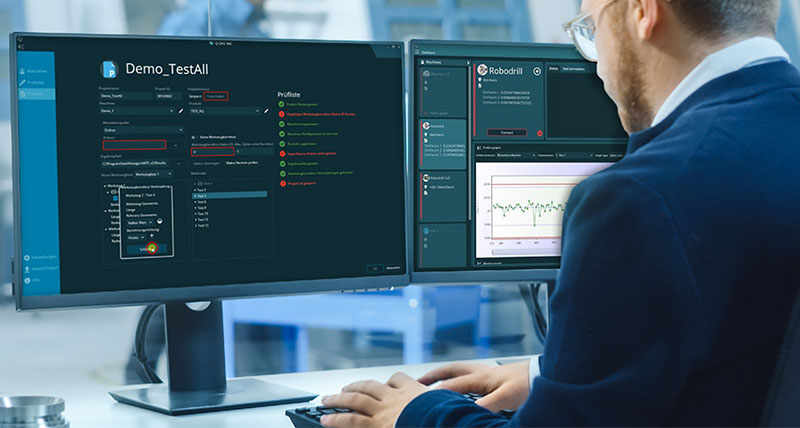

The new version of Q-DAS IMC intelligent machine control software establishes a link between tool data and measured values and enables clear communication between machine tools and the database with additional controllers.

Q-DAS, part of Hexagon’s Manufacturing Intelligence division, has launched Q-DAS IMC version 2 with additional controllers, integration of graphics in the dashboard, and a range of other new features.

Q-DAS IMC enables clear communication between machine tools with Siemens, Fanuc or Heidenhain controllers, and the Q-DAS database. It can manage different machine tools, measuring projects, and feature information.

The software forms the basis for improving data use within manufacturing processes and enables manufacturers to gain detailed insights into data and analyze the history to improve future processes. By creating added value from the preparation, presentation, and analysis of production data, it also helps to drive digitalization.

With the release of Q-DAS IMC V2, operators will no longer have to make manual corrections directly on machine tools. With the introduction of the ‘Manual Correction’ mode, machine operators can easily correct tools in a user-friendly software environment.

The machine operator can select the tools to be corrected in the software and enter the correction values for each tool. In the background, Q-DAS IMC checks the input for incorrect entries. The entered correction value is also checked against reaction limits so incorrect entries are identified. Previously, such input was made directly in the tool table of the controller without this check, increasing the risk of a tool crash or breakage. This new function, therefore, improves production safety. In addition, the operator can store events behind the manual correction in order to document the correction. This ensures quick and easy traceability for both operators and their colleagues. Tracking helps even inexperienced machine operators to learn from experienced colleagues and to see why corrections are made, and a knowledge database is created for each worker.

The main benefit of Q-DAS IMC lies in the ability to increase process capability, achieving a more stable process due to statistically-based tool corrections and fewer human decisions. Through installations at customers’ sites, process capability indices such as CPk have shown a significant increase through more stable manufacturing processes and more consistent production. As a result, the number of reject parts also decreased.

Q-DAS IMC is available within the Q-DAS product portfolio from Hexagon. The software is available on a flexible subscription-based licensing model. More information is available through local Hexagon and Q-DAS commercial operations and dealers.

To know more, please check Hexagon.