In Less Time Than It Takes A Rooster To Crow!

Companies who are looking for improvements and evolution of their product may have to reach out to external expertise. Unfortunately, it is not always possible to ship products, no matter how small they are. Creaform Go!SCAN 3D solutions help to overcome these obstacles … in less time than it takes a rooster to crow!

Challenge: Complicated logistics for shipping your products

Exceldor is a renowned brand of chickens raised in Quebec by local producers. Because they care about quality at every step, from the farm to the consumer, they wanted to optimize their packaging. They came up with the idea of wrapping their edible product in shrink-wrap foil and applying a sticker as identification. However, there was a slight downside to this new packaging idea: all adjustments would need to be done in their facility abroad, in Europe. Obviously, since chickens don’t fly, there was no way the factory could take the exact 3D measurements of Canadian chickens to generate accurate specifications for packaging.

Without those 3D measurements, it was impossible to improve the packaging. They wanted to have the perfect fit and labeling. Since they required shapes with dimensions of three standard categories (2kg, 1.5kg, and 1kg), Exceldor decided to turn to 3D technologies to advance their project.

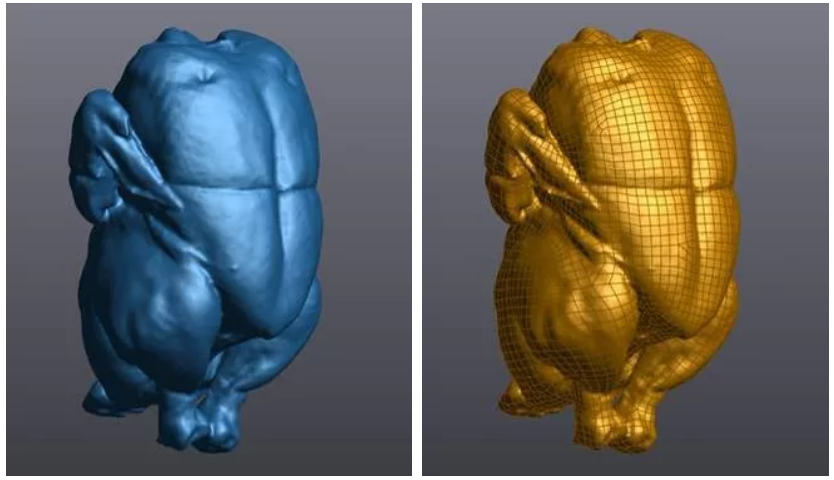

Solution: A 3D chicken model

With the help of the Creaform team, Exceldor went through the whole 3D scanning process, with all the advantages at the tips of their fingers. The goal was to perform a NURBS modelling to create a 3D chicken replica ready to be sent to Europe. To simplify the work, the chicken was placed on a rotisserie – and in a mere 5 minutes, every angle of the chicken was scanned with the Go!SCAN 3D, and the data was imported into VXmodel software. After a few optimizations of the scan, they exported the 3D data into a STEP file. Next, a mold was created by 3D printing, filled with silicon resin, and voilà – they had a perfect silicon replica of a chicken, ready to be packaged and labeled!

Solutions that do not sacrifice a single detail

Because Exceldor seeks quality down to the last detail, from the farm to the processing plant, they leave nothing to chance when it comes to promoting high-quality products from local producers. This is why the company was so satisfied with the 3D measuring services that Creaform provided: in the blink of an eye, they managed to send 3D replicas of the chickens to another continent and create the perfect packaging. And not a single chicken had to flap its wings!

To know more, please check Creaform.