When Vision Meets Decision.

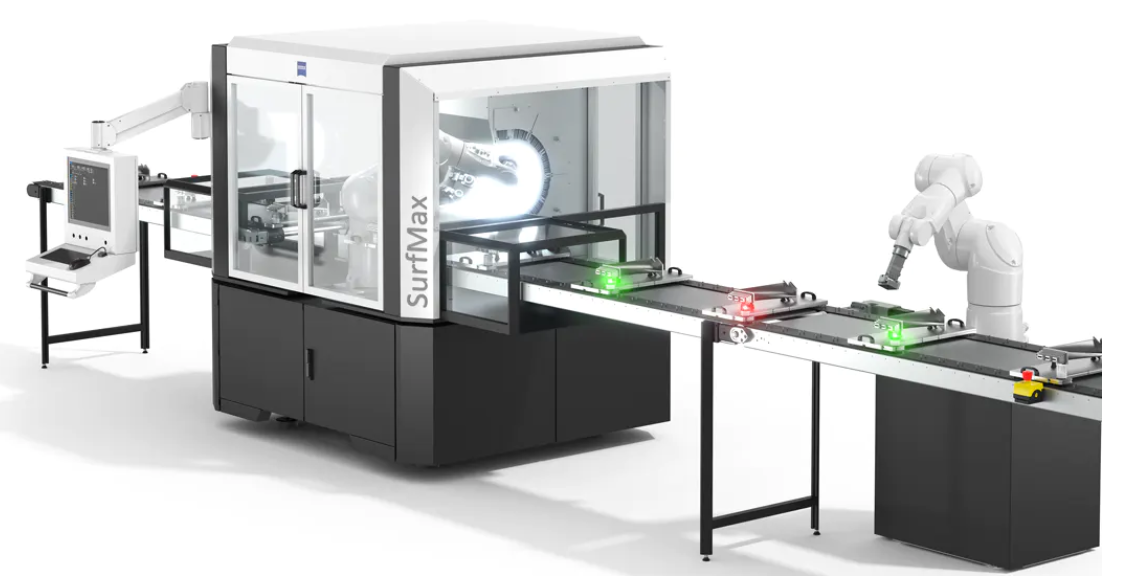

Zeiss SurfMax Surface Defect Detection has:

- Superior Imaging

By combining three channels of information it is possible to detect and separate defect classes. - Decision Making

With machine learning and tailored algorithms, ZEISS SurfMax analyzes, and classifies defects automatically. - Defect Scoring and Adjustable Detection Sensitivity

ZEISS SurfMax scores the severity of a defect and eliminates overkill and escapes to improve your yield.

Optical Technology and Machine Learning for Trusted Surface Defect Inspection

ZEISS SurfMax is a groundbreaking quality assurance solution for reliable high-speed visual defect detection: a perfect combination of deflectometry-based, high-resolution ZEISS optical sensors and machine learning-driven by in-house developed algorithms. ZEISS SurfMax can detect and classify relevant surface defects in products – consistently and in real-time.

Prevent Defective Parts from Getting to Your Customers

Thousands of components and products made for automotive, aerospace, medical, and consumer electronics have specific demands on proper surface quality, both for cosmetic and functional purposes.

Cosmetic Surface Quality

From a cosmetic perspective, how something appears or feels to a customer affects its value and its overall quality. This impacts the way a customer looks at your brand, reputation, and quality.

Functional Surface Quality

Many components also rely functionally on the quality of the surface. Defects can affect performance and reliability. For example, a scratch on a jet engine airfoil could cause cracking on the surface and engine failure.

Reliable for Many Surface Types

Inspect Countless Textures, Finishes, Forms and Shapes

Finish quality on a variety of surface textures.

ZEISS SurfMax is capable of inspecting surfaces ranging from matte to highly reflective, and regardless of color or transparency level. The ability of the system to separate the surface finish from defects enables a repeatable and effective inspection solution.

Gloss levels from matte to mirror finish surfaces.

ZEISS SurfMax provides high luminous output to achieve low cycle times when inspecting matte surfaces. On the opposite end of the gloss spectrum, ZEISS SurfMax excels on mirror-like surfaces where conventional imaging technologies break down.

Surface finish on a full palette of colors.

ZEISS SurfMax has the ability to inspect a wide variety of surfaces regardless of colors and can consistently span color variations. Typically, color may mask defects to the human eye. The system can detect and threshold defects on a wide variety of parts with a full palette of colors and their finishes. Part color does not inhibit effectiveness and ZEISS SurfMax can perform an inspection of black and white parts with the same effectiveness.

Transparency on any type of material.

Transparent surfaces are difficult for humans to inspect, as well as for traditional visual inspection systems. The ability to differentiate surfaces and inspect each for defects is possible with ZEISS SurfMax. Evaluation of the front, back, and interior defects on translucent materials is easily possible.

Wide range of complex forms and shapes.

ZEISS SurfMax provides maximum coverage of complex surfaces for inspection. This is obtained by collecting multiple acquisitions at several angles and orientations to see all of the relevant surfaces of the part. The ability to inspect convex, concave, or freeform surfaces, as well as edges and flat surfaces, ensures that ZEISS SurfMax handles the full inspection task.

To know more, please check Zeiss.