This content was originally written and published by the Novacam team on their website. Reproduced here from https://www.novacam.com/products/coordinate-measuring-machine/

Novacam non-contact optical Coordinate measuring machines (CMMs) offer superior performance both in the laboratory and on the production floor. They provide:

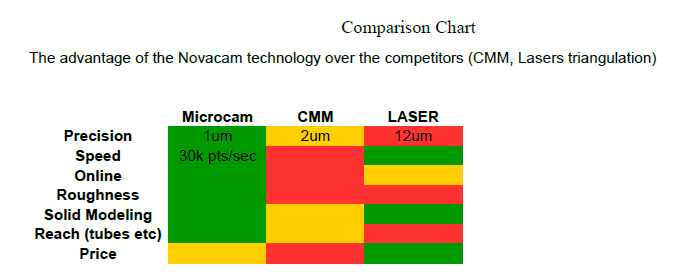

- High precision measurements (better than 1 µm)

- High-speed acquisition (2,100 to 100,000 3D point measurements per second)

- Simultaneous dimensional and surface inspection

- Small non-contact fiber-based probes (as small as 0.5 mm in diameter) for reaching inside tight spaces

- Automation by teaching with the joystick

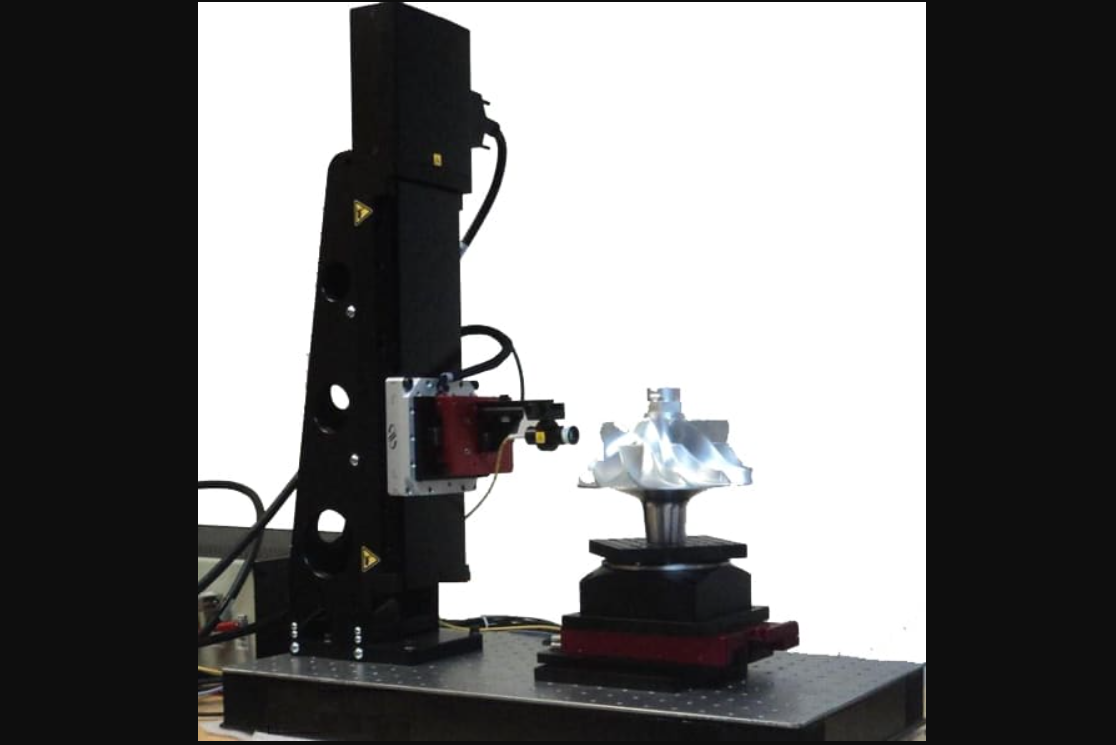

Novacam CMMs are equipped with robust and compact fiber-based probes, and can therefore easily inspect inside tight spaces and even in hostile environments. The CMMs are configured in size, speed, and scanning capabilities for the user’s needs and offer online integration capability, small footprint, and true portability. Depending on the workpiece, ultra-portable CMM inspection stations weighing 20 lbs (10 kg) are available.

Intuitive user interface

First-time users of Novacam CMMs feel comfortable with the intuitive user interface of our advanced metrology software. With a control device (joystick), it is very easy to start the measurement of objects of all levels of complexities. Experienced users appreciate features such as laser pointing and audio feedback which emulate the touch and feel of a conventional CMM.

Applications

The Novacam Coordinate measuring machines (CMMs) product line is made to adapt to any workpiece, regardless of surface properties. Thanks to the underlying technology, low-coherence interferometry, users can measure any type of material – transparent or opaque, specular, diffusive, polished, rough – with ease. Applications include deviation maps from CAD, geometric dimensioning and tolerancing (GD&T), flatness, surface profile, roughness, thickness, volume loss, parallelism, perpendicularity, the profile of a line, angularity, circularity, straightness, symmetry, cylindricity, datum qualification, circular runout, vibration.

Option to combine multiple inspection stations

Novacam profilometers can serve multiple CNC or CMM stations. Optimal scan paths can be achieved by the integration of Novacam’s and 3rd party software.

To know more, please check Novacam.