This content was originally written and published by the LMI team on their website. Reproduced here from https://lmi3d.com/company/digital-hub/blog/measuring-impossible-3d-line-confocal-sensors-part-1

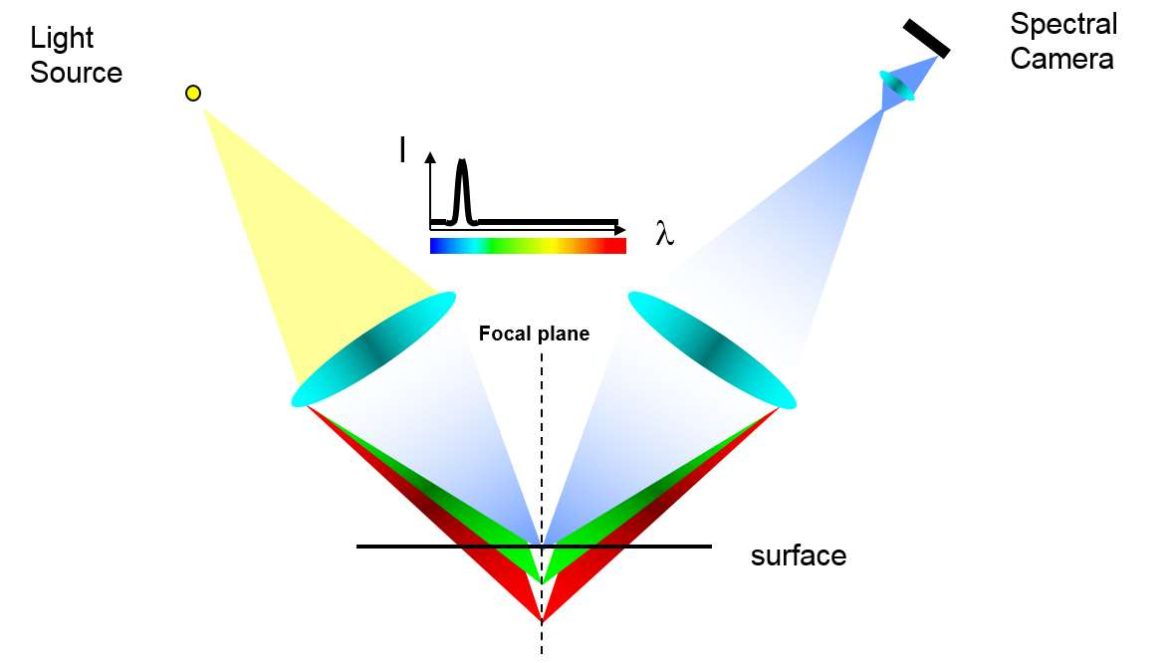

Line confocal imaging (LCI) is a unique optical technology for metrology requiring resolutions down to 50 nm. In the past, confocal technology was limited to a single point or multipoint sensors based on a coaxial design. With 3D Line Confocal Sensors, a major breakthrough is achieved using a novel off-axis confocal design that offers a line scan capability with numerous benefits over the traditional coaxial approach. In this two-part blog post, we examine the advantages of line confocal sensors over traditional point-based solutions.

What Makes 3D Line Confocal Sensors Unique

The key advantage of line confocal sensors is their ability to generate 3D topography (3D surface geometry), 3D tomography (multi-layer 3D geometry and 2D intensity), and 2D intensity data simultaneously over a 2k line scan at fast scan rates (e. g., 3 kHz). Confocal scanning avoids unwanted reflections from shiny metal surfaces and the off-axis arrangement is what permits multi-layer (tomography) scanning.

In addition, confocal sensors are much easier to mount to acquire high-quality scan data with the angular performance of +/- 20 degrees on mirror-like surfaces, and +/- 80 degrees on opaque, matte surfaces. Excellent angular performance makes line confocal sensors less sensitive to surface orientation when acquiring scan data, and line confocal scanning can handle just about any surface—from transparent, mirror-like to opaque and shiny. Before line confocal was possible, single or multiple point coaxial confocal systems were the standard, but required long scanning acquisition to generate a profile or area and were limited to measuring the top surface only.

Application Examples

Curved Edge Display Inspection

Line confocal sensors are used to scan, measure, and inspect the profile of curved screen glass used in cell phone and tablet designs at a surface angle of up to +/- 20 degrees, making this sensor ideal for quality control of 2.5D and 3D display glass. Conventional vision solutions can only capture quality data on surface angles of +/- 7 degrees or less.

Multi-Layered Transparent Material Inspection

Line confocal sensors are ideal for transparent material inspection and quality control. One of the key applications in capturing the surface of mobile device displays and detecting layers inside and under the screen.

The combination of 3D tomography (multi-layer) and 2D intensity imaging is used to identify defects such as delamination, scratches, or dust on the surface or inside of laminated glass, mobile phone displays, or any other type of transparent multilayered material like sealed medical packages. And, contrary to other types of imaging systems, line confocal sensors detect not only the location of the defect, but they also identify in which layer the defect exists. The sensor even measures the dimensions of the defect down to the sub-micron level.

Additional Advantages of Using 3D Line Confocal Sensor

• No additional filtering is required for analysis

• Ability to scan and measure materials with any color combination

• Ability to measure all surface types including mirror-like, glossy, transparent, translucent, curved, convex, concave, soft, fragile, or porous

• Metrology-grade resolution and accuracy are provided at high speed (up to 3 kHz at full measurement range)

• Easy to mount and acquire clean scan data on any surface feature

To know more, please check LMI.