This article was originally written and published by AZom on their website(https://www.azom.com/article.aspx?ArticleID=19851).

With the aging population, the demand for medical tools and devices, such as stents and blood glucose test strips, is increasing. These devices play a key role in improving an individual’s quality of life, so quality assurance, including surface metrology, is essential before their distribution.

Multiple parameters need to be analyzed for each tool, and so the use of multi-sensor systems from FRT is highly beneficial as these can ensure the materials are of high-quality, reproducible, and meet government regulations with the use of a single instrument. Besides, they reduce time, minimize reclamations and rejects, and aid companies with future technology development.

Medical technology tools, such as blood glucose test strips, lab-on-a-chip devices, artificial joints, and stents, are crucial interventions to help improve an individual’s quality of life.1,2 For example, artificial joint replacements offer people a significant improvement in their range of movement and a reduction in persistent pain.3 The National Joint Registry estimates there is approximately 160,000 hip and knee joint replacements performed every year in England and Wales, and with the aging population, this number is set to rise.4 This increasing demand can be seen across the board for medical devices, with the global medical device market size predicted to increase from 425.5 billion US dollars in 2018 to 612.7 billion US dollars in 2025.5

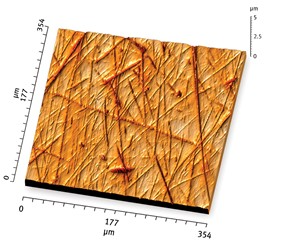

As these tools are used for medical applications, their quality and reproducibility are essential to guarantee patients’ safety and efficacy. As such, they are subject to strict requirements from the Medical Product Act (MPA). Many parameters, including the dimensions, optical, mechanical, electronic, or chemical properties of these devices, can be critical for their function. For example, in artificial joints, the head must be smooth to aid insertion, while the rest of the joint must have a certain roughness for efficient adhesion with the surrounding tissue. There only a few nanometers difference between the two surface types, but it has a significant impact on the joint function.

Image 1: Roughness of an artificial knee joint

Image Credit: FRT

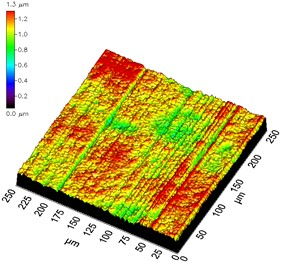

Furthermore, coatings on these joints are used to minimize rejection, and the thickness of this coating impacts its effectiveness. Therefore, three-dimensional metrology is essential to ensure these tools meet the stringent MPA criteria and perform as required.1

Image 2: Layer thickness of a transparent adhesive film

Image Credit: FRT

Accurate and Reliable Measurement of Medical Technology Tools

Depending on the type of medical tool, different characteristics need to be measured, often in different resolutions and processes. Examples of the types of measurements required for various medical technology tools are shown in the table below.2

| Medical Tool | Measurement Requirements | ||

| Lab-on-a-chip | Parallelism | Height | Width |

| Microplates | FlatnessStep height | Pass/fail evaluation | Roughness |

| Blister Packaging | Embossing PatternsAuthenticity | Coat thicknessGeometry | DimensionsTopography |

| Blood Sugar Test Strips | Step height | Thickness | |

| Syringe Needle | AngleRoughness | GeometryStep height | HeightWidth |

| Stent | Roughness | Uniformity |

Multi-sensor metrology instruments can provide numerous different measurement tests with one automated set-up, offering maximum flexibility in the fast-changing and challenging medical devices environment.2

These measurements provide quality assurance on the properties and quality of products. They offer important information that medical technology companies can use to help advance new or existing technology. However, typically, several different instruments are required to obtain all the necessary data, increasing time and cost.6

FRT Offer High-Quality and Flexible Surface Metrology

FRT has 25 years’ experience in metrology and is one of the world’s leading suppliers of surface measuring instruments for the medical industry.2 Their optical Multi-Sensor Technology can be fitted with chromatic white light point sensors, white light interferometers, confocal microscopes, and optical film thickness sensors, which enable tests to be carried out without sample contact, in three dimensions, and with high-precision. Atomic force microscopy (AFM) can also be added to these multi-sensor instruments, allowing for further tests and sub-nanometer resolution to be achieved.2,6

These surface measuring systems are designed with flexibility in mind; the type and number of sensors can be selectively chosen and arranged within the system to meet each customer’s specific requirements. Sensors can also be retrofitted for flexible adaptation of future measuring tasks. And powerful in-house software has also been specially developed to ensure the data collection and analysis of this module-based system is fluent and easy-to-use.2

These unique characteristics enable a wide variety of measurements, including topography, roughness, sample or film thickness, and step height, to be combined in a single tool. The flexible, expandable, and efficient FRT multi-sensor systems ensure manufacturers can be confident of the quality and reproducibility of their products and help drive the development of innovations. These instruments also help companies comply with government regulations and reduce time and cost by avoiding reclamations and high reject rates.2

References

- FRTmetrology.com. (2020). In the Best Health Thanks to Artificial Hips, Dental Implants or Blood Sugar Strips. https://frtmetrology.com/en/news/detail/127801ea523cbf313725fcb60289fbf8-21/

- FRTmetrology.com. (2020). Medical Technology. https://frtmetrology.com/en/applications-industries/medizintechnik/

- NHS.uk (2020). Overview: Hip Replacement. https://www.nhs.uk/conditions/hip-replacement/

- NJRcentre.org.uk. (2020). Joint Replacement Statistics. https://www.njrcentre.org.uk/njrcentre/Patients/Joint-replacement-statistics

- Fortunebusinessinsights.com. (2020) Medical Devices Market. https://www.fortunebusinessinsights.com/industry-reports/medical-devices-market-100085

- FRTmetrology.com. (2020). It is no Longer Possible Without: Non-Contact Surface Measurement Technology for Perfect Medical Technology. https://frtmetrology.com/en/news/detail/medical-engineering/